Prussian blue derivative Fe-Co-Ni sulfide and preparation method and application thereof

A technology of cobalt-nickel sulfide and Prussian blue, applied in electrical components, battery electrodes, circuits, etc., can solve the problem that the electrochemical performance of materials needs to be improved, and achieve industrialized large-scale application, simple preparation method, and high specific capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add potassium ferricyanide, potassium cobalt cyanide, and potassium nickel cyanide with a molar ratio of 1:1:1 into 0.2mol / L hydrochloric acid solution to make potassium ferricyanide, potassium cobalt cyanide, and potassium nickel cyanide The concentrations are respectively 0.1 mol / L; polyvinylpyrrolidone equivalent to 40 times the total mass of potassium ferricyanide, potassium cobalt cyanide, and potassium nickel cyanide is added. The solution was placed in an oven and heated at 80°C for 24 hours. Then centrifuge in a high-speed centrifuge at 10000 rpm to obtain the precipitate, wash it with deionized water and ethanol, and dry to obtain the iron-cobalt-nickel-based cubic structure Prussian blue powder, the structure of which is as figure 1 Shown.

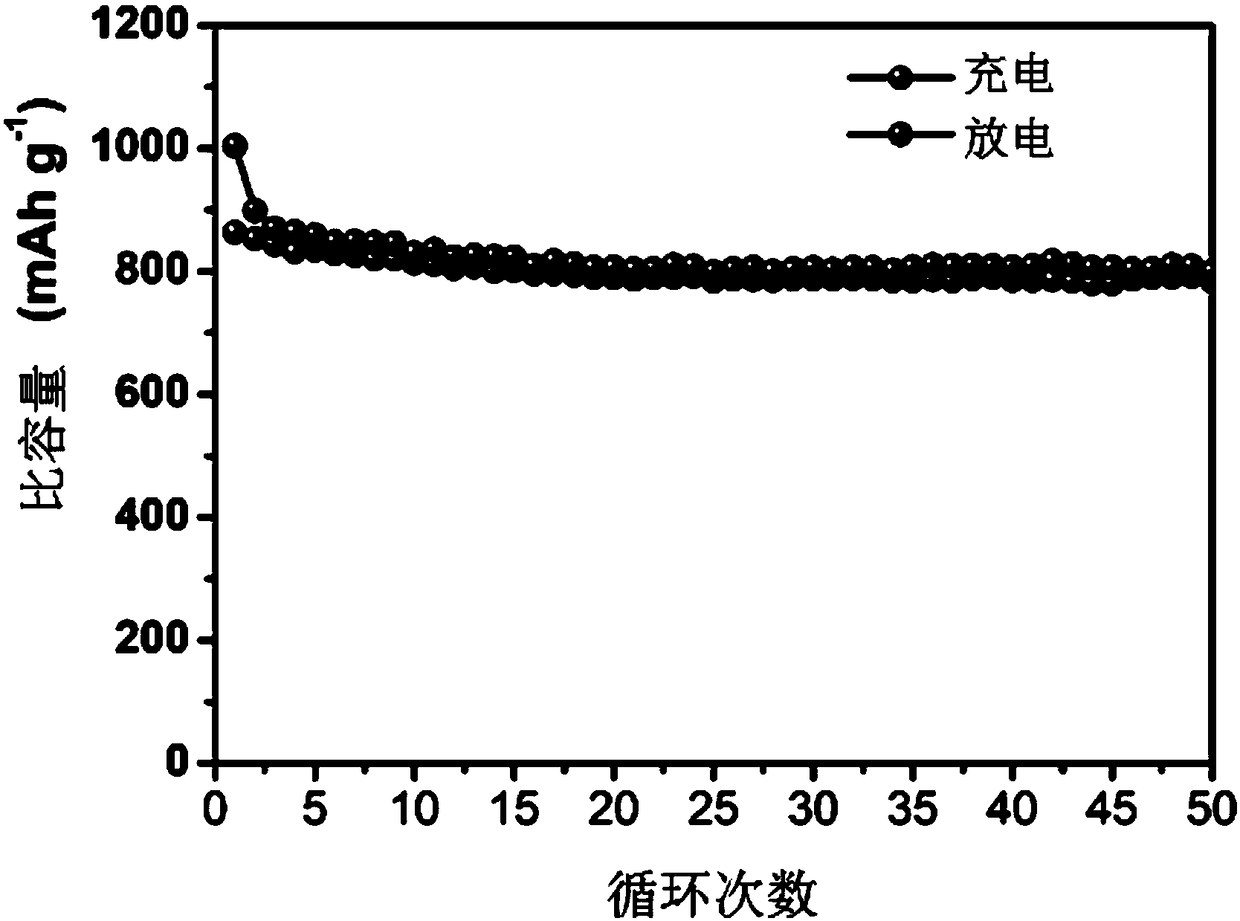

[0033] Mix the iron-cobalt-nickel-based cubic structure Prussian blue powder prepared above with sulfur powder and place it in a tube furnace, and heat it to 600°C at a heating rate of 2°C / min and keep it for 2 hours to obtai...

Embodiment 2

[0035] Add sodium ferricyanide, sodium cobalt cyanide and sodium nickel cyanide with a molar ratio of 1:1:1 into 0.5mol / L hydrochloric acid solution to make the sodium ferricyanide, sodium cobalt cyanide and sodium nickel cyanide The concentrations are respectively 0.1 mol / L; polyvinylpyrrolidone equivalent to 5 times the total mass of sodium ferricyanide, sodium cobalt cyanide and sodium nickel cyanide is added. The solution was placed in an oven and heated at 80°C for 24 hours. Then, the precipitate is obtained by centrifugation in a high-speed centrifuge with a rotation speed of 10,000 rpm, washed with deionized water and ethanol, and dried to obtain iron-cobalt-nickel-based cubic structure Prussian blue powder.

[0036] The iron-cobalt-nickel-based cubic structure Prussian blue powder prepared above is mixed with sulfur powder and placed in a tube furnace, heated to 800°C at a temperature rise rate of 5°C / min, and kept for 2h to obtain the Prussian blue Derived Fe-Co-Ni sulf...

Embodiment 3

[0038] Add potassium ferricyanide, potassium cobalt cyanide, and potassium nickel cyanide with a molar ratio of 5:3:2 to 0.2mol / L hydrochloric acid solution to make potassium ferricyanide, potassium cobalt cyanide, and potassium nickel cyanide The concentrations are respectively 0.5mol / L, 0.3mol / L and 0.2mol / L; polyvinylpyrrolidone equivalent to 40 times the total mass of potassium ferricyanide, potassium cobalt cyanide, and potassium nickel cyanide is added. The solution was placed in an oven and heated at 80°C for 24 hours. Then, the precipitate is obtained by centrifugation in a high-speed centrifuge with a rotation speed of 10,000 rpm, washed with deionized water and ethanol, and dried to obtain iron-cobalt-nickel-based cubic structure Prussian blue powder.

[0039] The iron-cobalt-nickel-based cubic phase Prussian blue powder prepared above is mixed with sulfur powder and placed in a tube furnace, heated to 600°C at a heating rate of 2°C / min, and kept for 2h to obtain the Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com