Animal and plant source anti-fatigue chewable tablets and preparation method thereof

A technology of anti-fatigue and chewable tablets, which is applied in the field of animal and plant source anti-fatigue chewable tablets and its preparation, can solve the problems of single function, large dosage, inconvenient carrying, etc. damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

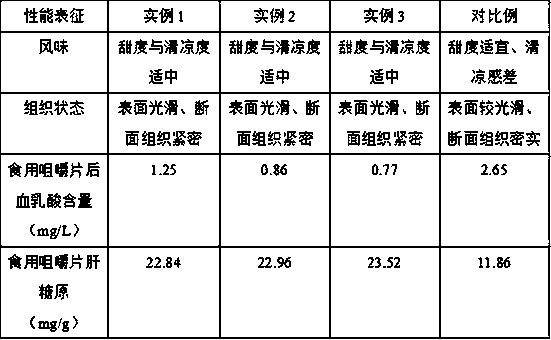

Examples

example 1

[0027] Take 300g of defatted eel meal, add 3L of deionized water, stir at 300r / min for 30min, add enzyme amount 1000U / g alkaline protease, enzymatically hydrolyze at 50℃, pH 7.5 for 2h, then add enzyme amount 1000U / g Neutral protease, incubate at pH 7.0 for 3 hours to obtain enzymatic hydrolysate. Place the enzymatic hydrolysate in a high-temperature sterilization pot, sterilize it at 120°C for 20 minutes, and then transfer it to a centrifuge at a rate of 30,000 r / Min centrifugation to obtain the precipitate, the precipitate was dried in a freeze-drying box for 15 hours to obtain eel oligopeptides, 500g of tea tree sprouts were taken, washed twice with deionized water and then dried naturally, and then added to a pulverizer to pulverize, over 60 Mesh sieve, take 100g of the tea tree bud powder after sieving, add 1L of deionized water, and adjust the pH to 2 with 10% acetic acid, extract at 80℃ for 2h, and then transfer to the centrifuge at 3000r / min Centrifuge for 10 minutes, ...

example 2

[0029] Take 350g of defatted eel meal, add 3L of deionized water, stir at 350r / min for 35min, add enzyme amount 1250U / g alkaline protease, enzymatically hydrolyze at 52℃, pH 7.7 for 2h, then add enzyme amount 1250U / g Neutral protease, incubate at pH 7.3 for 3.5 hours to obtain enzymatic hydrolysate. Place the enzymatic hydrolysate in a high-temperature sterilization pot, sterilize it at 123°C for 25 minutes, and then transfer it to a centrifuge for 3500r / min centrifugation to obtain the precipitate, put the precipitate in a freeze-drying box for 17h to obtain eel oligopeptides, take 650g of tea tree sprouts, wash with deionized water twice, then dry naturally, and then add to the grinder to pulverize. 60 mesh sieve, take 150g of tea tree sprout powder after sieving, add 1L of deionized water, and adjust the pH to 3 with 10% acetic acid, extract at 85℃ for 2.5h, and then transfer it to the centrifuge to 3500r Centrifuge for 13 min. Take the supernatant. Concentrate the supernat...

example 3

[0031] Take 400g of defatted eel meal, add 4L of deionized water, stir at 400r / min for 40min, add enzyme amount 1500U / g alkaline protease, enzymatically hydrolyze at 55℃, pH 8.0 for 3h, then add enzyme amount 1500U / g Neutral protease, incubate at pH 7.5 for 4 hours to obtain enzymatic hydrolysate. Place the enzymatic hydrolysate in a high-temperature sterilization pot, sterilize it at 125°C for 30 minutes, and then transfer it to a centrifuge at 4000r / After centrifugation for minutes, the precipitate was dried in a freeze-drying cabinet for 20 hours to obtain eel oligopeptides. 800g of tea tree sprouts were taken, washed with deionized water for 3 times, and then dried naturally, and then added to a pulverizer for pulverization. Mesh sieve, take 200g of tea tree bud powder after sieving, add 2L deionized water, adjust pH to 3 with 10% acetic acid, extract at 90℃ for 3h, then transfer to centrifuge at 4000r / min Centrifuge for 15 minutes, take the supernatant, concentrate the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com