Makeup removing lotion and preparation method thereof

A technology of cleansing milk and emulsifier, applied in the field of cleansing milk and its preparation, can solve the problems of no skin care function, strong irritation, strong degreasing power, etc., and achieve the effect of reducing the formation of melanin, reducing skin damage, and reducing wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

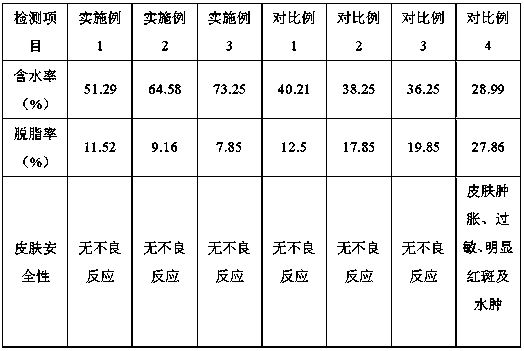

Examples

Embodiment 1

[0027] Each phospholipase A2: purchased from Novozymes (Novozymes).

[0028] Shells: obtained from discarded oyster shells in the seafood market; dispersant 5040: purchased from Guangzhou Desong Chemical Co., Ltd.

[0029] Emulsifier: Take soybean lecithin and add absolute ethanol at a mass ratio of 1:9, and extract under reflux at 35°C for 300min.

[0030] Repeat the reflux extraction process twice, combine the extracts, filter, take the filtrate and rotary evaporate, wash the rotary evaporator A with acetone, remove the acetone by distillation under reduced pressure, and dry in vacuum for 18 hours to obtain the dry extract, calculated in parts by mass, take 1 part Dry extract, 2 parts anhydrous CaCl 2 , 10 parts Tris-HCl buffer, 0.1 part phospholipase A 2 , reflux reaction at 35°C for 7 hours to obtain the product. The product was distilled under reduced pressure and dried under vacuum at 0.08MPa for 18 hours to obtain the dried product. In terms of parts by mass, 18 parts...

Embodiment 2

[0035] Each phospholipase A2: purchased from Novozymes (Novozymes).

[0036] Shells: obtained from discarded oyster shells in the seafood market; dispersant 5040: purchased from Guangzhou Desong Chemical Co., Ltd.

[0037] Emulsifier: Take soybean lecithin and add absolute ethanol at a mass ratio of 1:9, and extract under reflux at 37°C for 35 minutes.

[0038] Repeat the reflux extraction process twice, combine the extracts, filter, take the filtrate and rotary evaporate, wash the rotary evaporator A with acetone, remove the acetone by distillation under reduced pressure, and dry in vacuum for 22 hours to obtain the dry extract, calculated in parts by mass, take 1 part Dried extract, 2~32 parts anhydrous CaCl 2 , 12 parts of Tris-HCl buffer, 0.1 part of phospholipase A 2 , reflux reaction at 36°C for 7 hours to obtain the product. The product was distilled under reduced pressure and dried in vacuum at 0.08MPa for 20 hours to obtain the dried product. In terms of parts by ma...

Embodiment 3

[0043] Each phospholipase A2: purchased from Novozymes (Novozymes).

[0044] Shells: obtained from discarded oyster shells in the seafood market; dispersant 5040: purchased from Guangzhou Desong Chemical Co., Ltd.

[0045] Emulsifier: take soybean lecithin and add absolute ethanol at a mass ratio of 1:9, reflux extraction at 40°C for 40 minutes, repeat the reflux extraction process 3 times, combine the extracts, filter, take the filtrate and rotary evaporate, wash the rotary evaporator A with acetone, Remove acetone by distillation under reduced pressure, and dry in vacuum for 24 hours to obtain a dry extract. In terms of parts by mass, take 2 parts of the dry extract and 3 parts of anhydrous CaCl 2 , 15 parts of Tris-HCl buffer, 0.2 parts of phospholipase A 2 , reflux reaction at 38°C for 8 hours to obtain the product. The product was distilled under reduced pressure and dried under vacuum at 0.08MPa for 24 hours to obtain the dried product. In terms of parts by mass, 25 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com