High visible-light catalytic activity material for BiOCl/ZnO heterojunction and preparation method thereof

A catalytically active material and visible light technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as limited contact area of semiconductors, separation of photogenerated electron-hole pairs, and hindered transfer rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

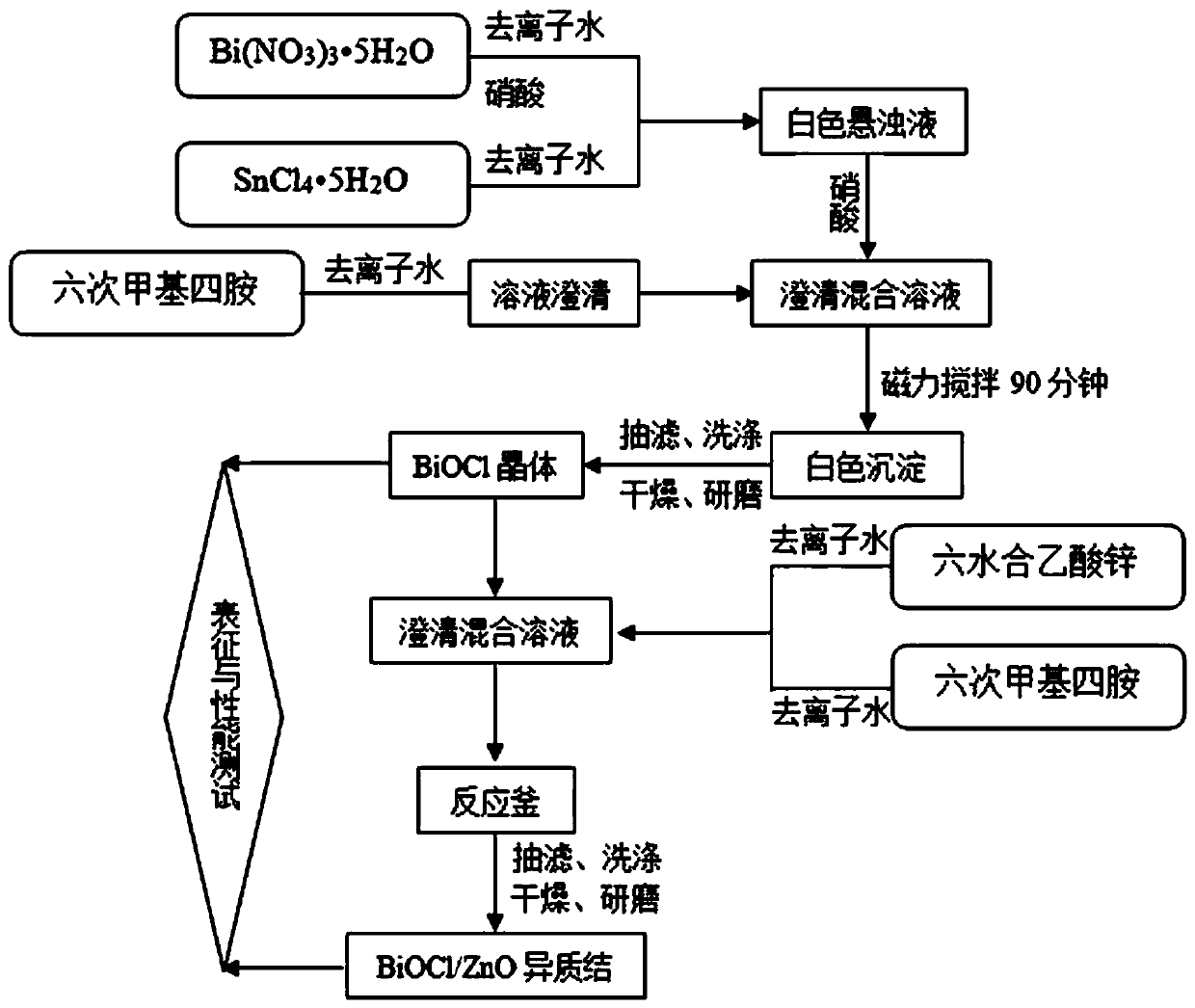

[0041] refer to figure 1, a preparation method of a BiOCl / ZnO heterojunction highly visible light catalytic active material, comprising the steps of:

[0042] 1) Bi(NO 3 ) 3 • 5H 2 O was dissolved in deionized water, stirred evenly, and nitric acid was added dropwise therein to form a clear solution A;

[0043] 2) The crystallized SnCl 4 Dissolve in deionized water, stir evenly, and make solution B;

[0044] 3) Mix solution A and solution B according to the molar ratio of Bi:Sn=(0.5-2):1, stir evenly, a white suspension will form during the stirring process, add nitric acid dropwise, and make a clear mixture C ;

[0045] 4) Add hexamethylenetetramine aqueous solution dropwise to the mixed solution C, and continue to stir for 90 minutes to produce a white precipitate, and the reaction product is suction filtered, washed, dried, cooled and ground to obtain flower-shaped BiOCl crystals;

[0046] 5) Dissolve zinc acetate hexahydrate and hexamethylenetetramine in different d...

example 1

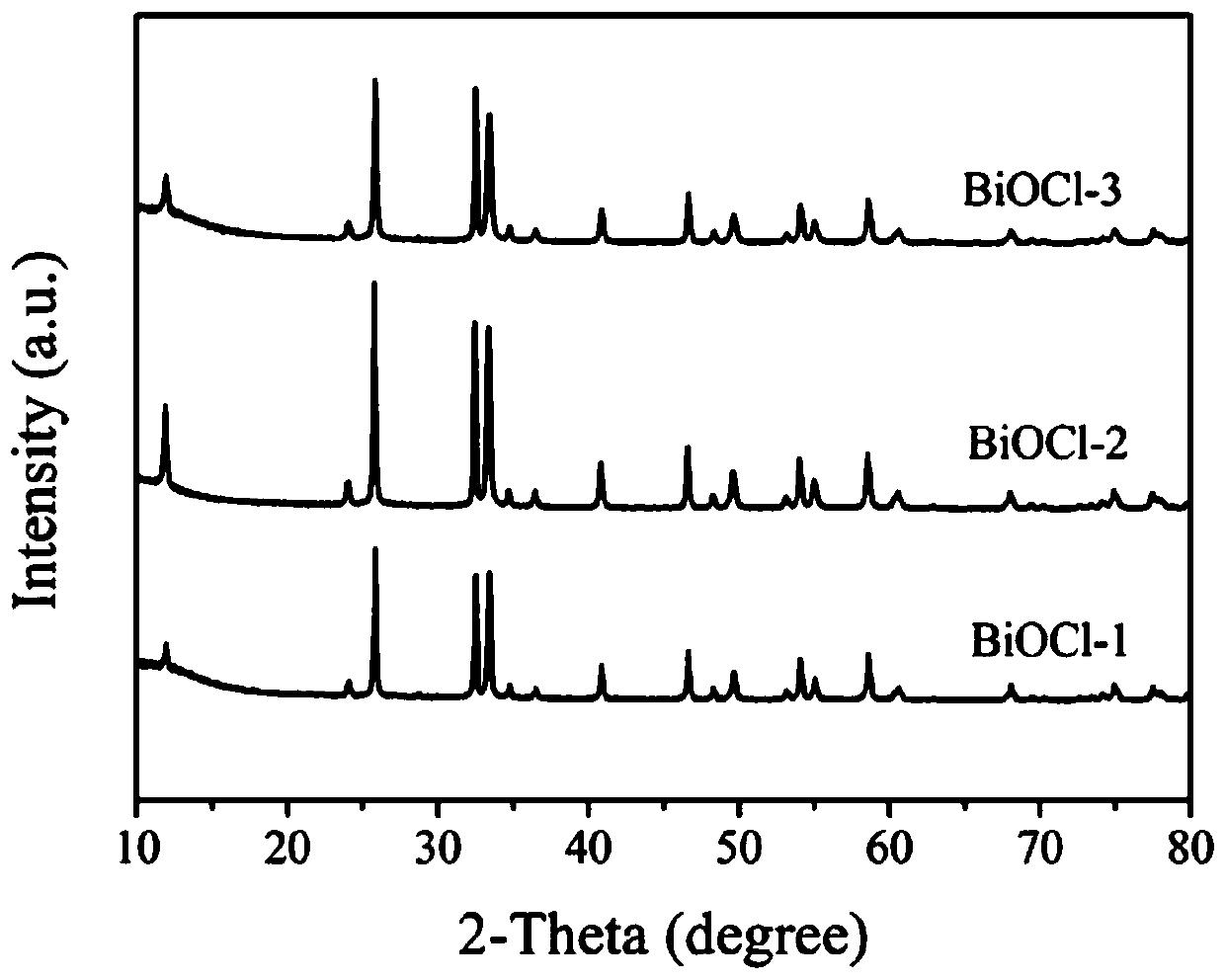

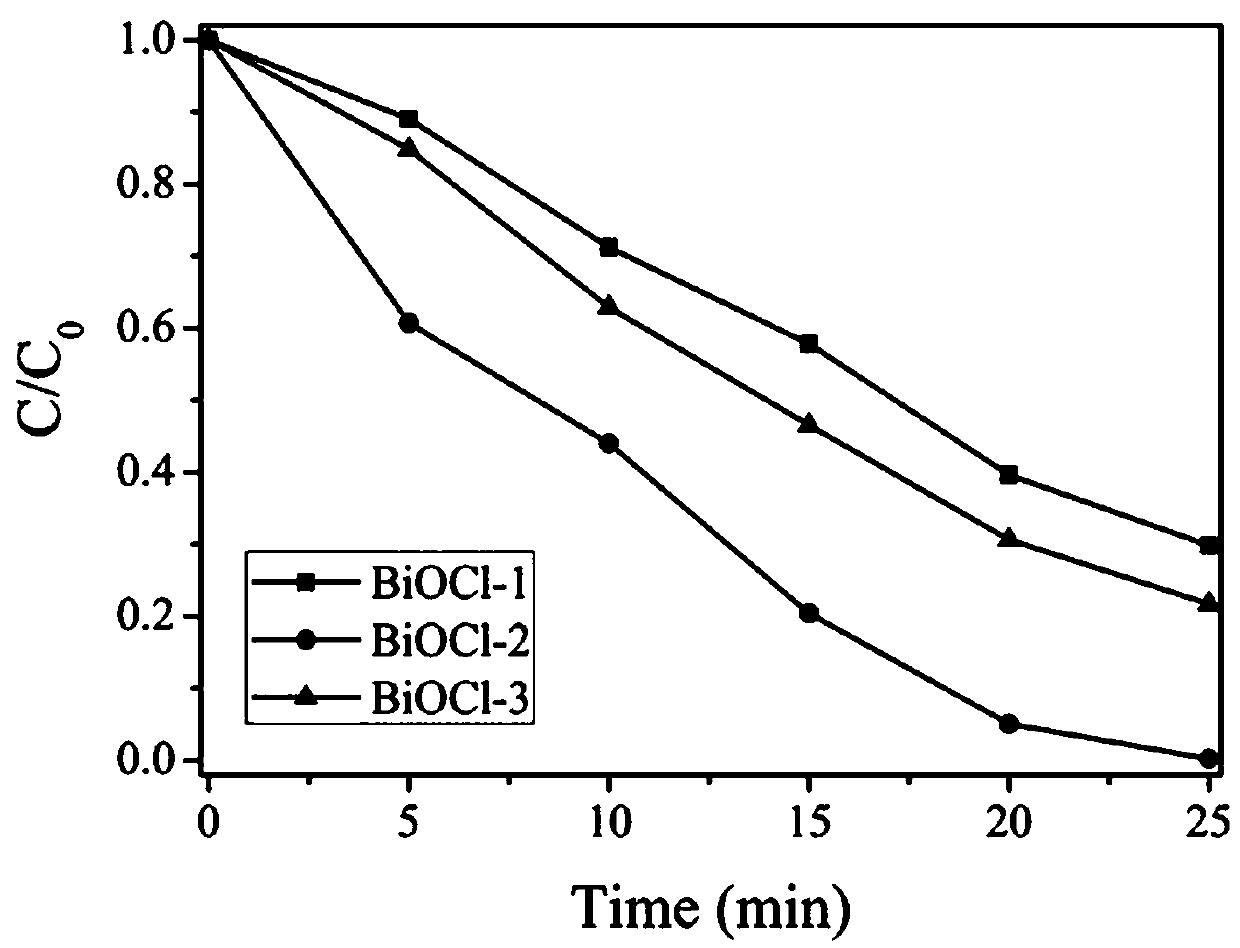

[0058] Example 1, prepare pure BiOCl when the molar ratio is Bi:Sn=0.5:1:

[0059] Take 10mmol Bi(NO 3 ) 3 • 5H 2 O was dissolved in 100mL deionized water, stirred evenly, and then 1mL nitric acid was added dropwise to it every 5 minutes until a clear solution A was formed; 20mmol crystalline SnCl 4 Dissolve in 100mL deionized water, stir well to make solution B; then stir and mix solution A and solution B evenly, a white suspension will be formed during the stirring process, continue to add 1mL nitric acid every 5 minutes until clear Mixed solution C: Dissolve 2 mmol of hexamethylenetetramine in 400 mL of deionized water to form solution I. After the solution of solution I is complete, add it to mixed solution C, and keep stirring for 90 min to produce a large amount of white precipitate. The resulting product Suction filtration, repeated washing with deionized water and absolute ethanol three to five times, and finally drying at 60°C for 12 hours; cooling and grinding to ...

example 2

[0060] Example 2, preparing pure BiOCl when the molar ratio is Bi:Sn=1:1:

[0061] Take 10mmol Bi(NO 3 ) 3 • 5H 2 O was dissolved in 100mL deionized water, stirred evenly, and then 1mL nitric acid was added dropwise to it every 5 minutes until a clear solution A was formed; 10mmol crystalline SnCl 4 Dissolve in 100mL deionized water, stir well to make solution B; then stir and mix solution A and solution B evenly, a white suspension will be formed during the stirring process, continue to add 1mL nitric acid every 5 minutes until clear Mixed solution C: Dissolve 2mmol hexamethylenetetramine in 400mL deionized water to make solution I. After the solution I solution is complete, add it to mixed solution C and keep stirring for 90min to produce a large amount of white precipitate. Pump the resulting product Filter, wash with deionized water and absolute ethanol three to five times, and finally dry at 60°C for 12 hours; cool and grind to obtain a powder that is pure BiOCl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com