Grape residue sludge-based high-efficiency biological carbon and preparation method and application thereof

A technology of grape pomace and biochar, which is applied in the field of solid waste treatment and recycling, can solve the problems of adverse social impact, lower economic value, and no comprehensive utilization, and achieve low cost, simple process, and strong adsorption and decontamination capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

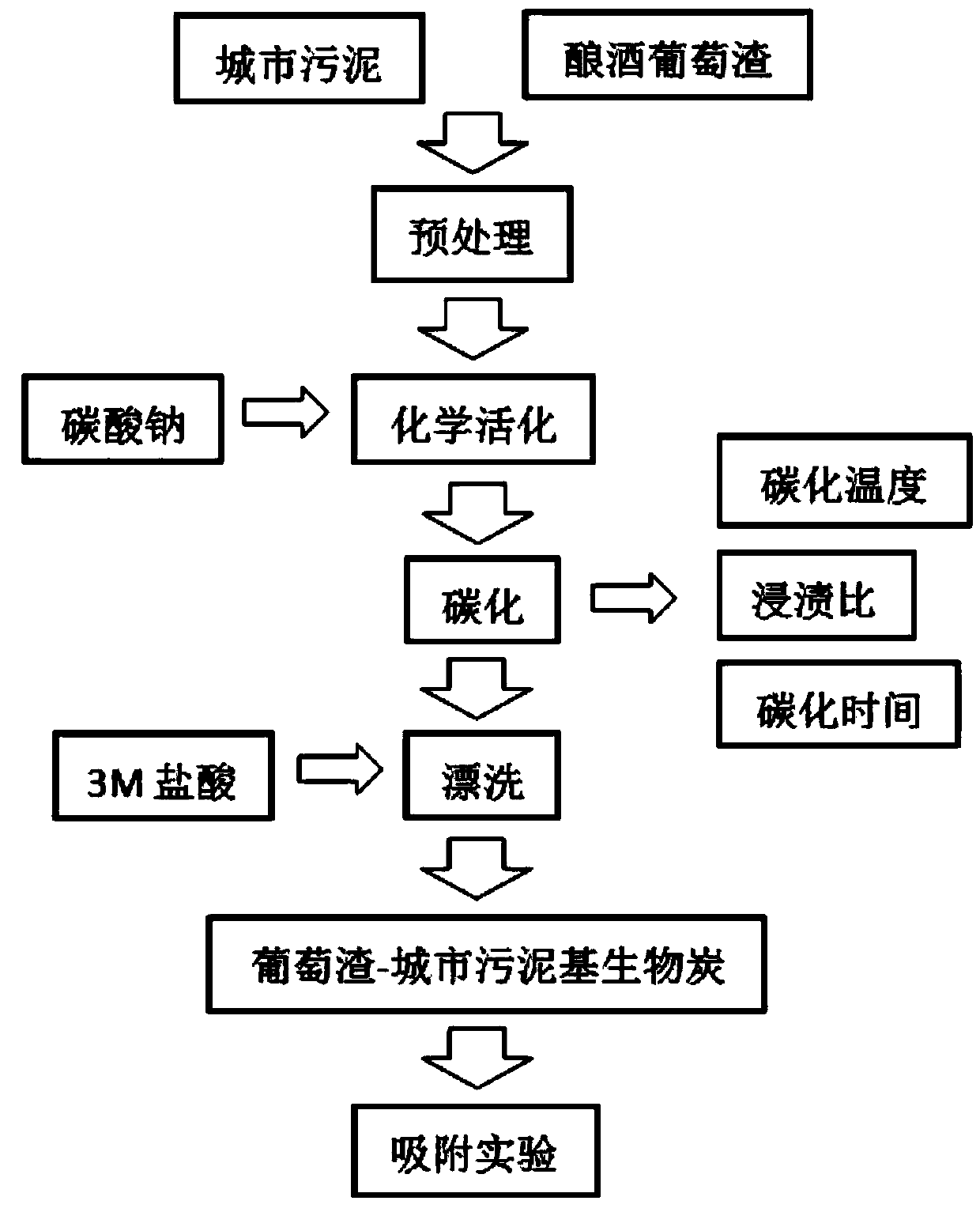

[0034] Embodiments of the present invention provide a method for preparing the above-mentioned grape marc sludge-based high-efficiency biochar, such as figure 1 As shown, it includes the following steps:

[0035] S1. Press filter the urban sludge from the urban sewage treatment plant, and dry it at 100-115°C until the moisture content is below 10%, to obtain dried sludge; press filter the grape pomace, and dry it at 100-115°C, that is Dried pomace.

[0036] S2. In parts by weight, mix and grind 0.5-2 parts of dried sludge and 1-4 parts of dried grape pomace, add a chemical activator, and dip for activation for 20-30 hours.

[0037] In this embodiment, the dried sludge and dried grape pomace can be crushed and ground separately, and passed through a 20-mesh stainless steel sieve, or the dried sludge and dried grape pomace can be mixed and then crushed and ground, passed through a 20-mesh stainless steel sieve, and the mixing and grinding The sequence is not limited.

[0038]...

Embodiment 1

[0049] This embodiment provides a kind of high-efficiency biochar based on grape marc sludge, such as figure 1 As shown, it is prepared according to the following preparation method:

[0050] (1) Air-dry the remaining sludge (with a moisture content of about 80%) collected from the tail end of the belt filter press of Tangxun Lake Sewage Treatment Plant in Wuhan City under natural conditions, and put it into a blast drying oven at 105°C to dry until constant Heavy, remove debris such as stones, crush and grind with a crusher, pass through a 20-mesh stainless steel sieve, and perform the same pretreatment on wine grape residue as urban sludge.

[0051] (2) The above-mentioned dry and ground municipal sludge and grape pomace are fully mixed into a mixed raw material in a ratio of 1:2 by weight, and Na 2 CO 3 As an activator, the mass ratio of the activator to the mixed raw material is 0.5:1, and a certain volume of deionized water is added to stir, so that the mixed raw materi...

Embodiment 2

[0057] This embodiment provides a kind of high-efficiency biochar based on grape marc sludge, such as figure 1 As shown, it is prepared according to the following preparation method:

[0058] (1) Air-dry the remaining sludge (with a moisture content of about 80%) collected from the tail end of the belt filter press of Tangxun Lake Sewage Treatment Plant in Wuhan City under natural conditions, and put it into a blast drying oven at 105°C to dry until constant Heavy, remove debris such as stones, crush and grind with a crusher, pass through a 20-mesh stainless steel sieve, and perform the same pretreatment on wine grape residue as urban sludge.

[0059] (2) The above-mentioned dry and ground municipal sludge and grape pomace are fully mixed in a ratio of 1:2 by weight, and the 2 CO 3 As an activator, the mass ratio of the activator to the mixed raw material is 3:1, and a certain volume of deionized water is added to stir, so that the mixed raw material is in full contact with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com