Method for producing cellulose protic ionic liquid by using cellulose

A technology of ionic liquid and cellulose, applied in the chemical field, can solve the problems of poor controllability of reaction, severe cellulose degradation, complicated preparation process, etc., and achieve the effect of easy preparation and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

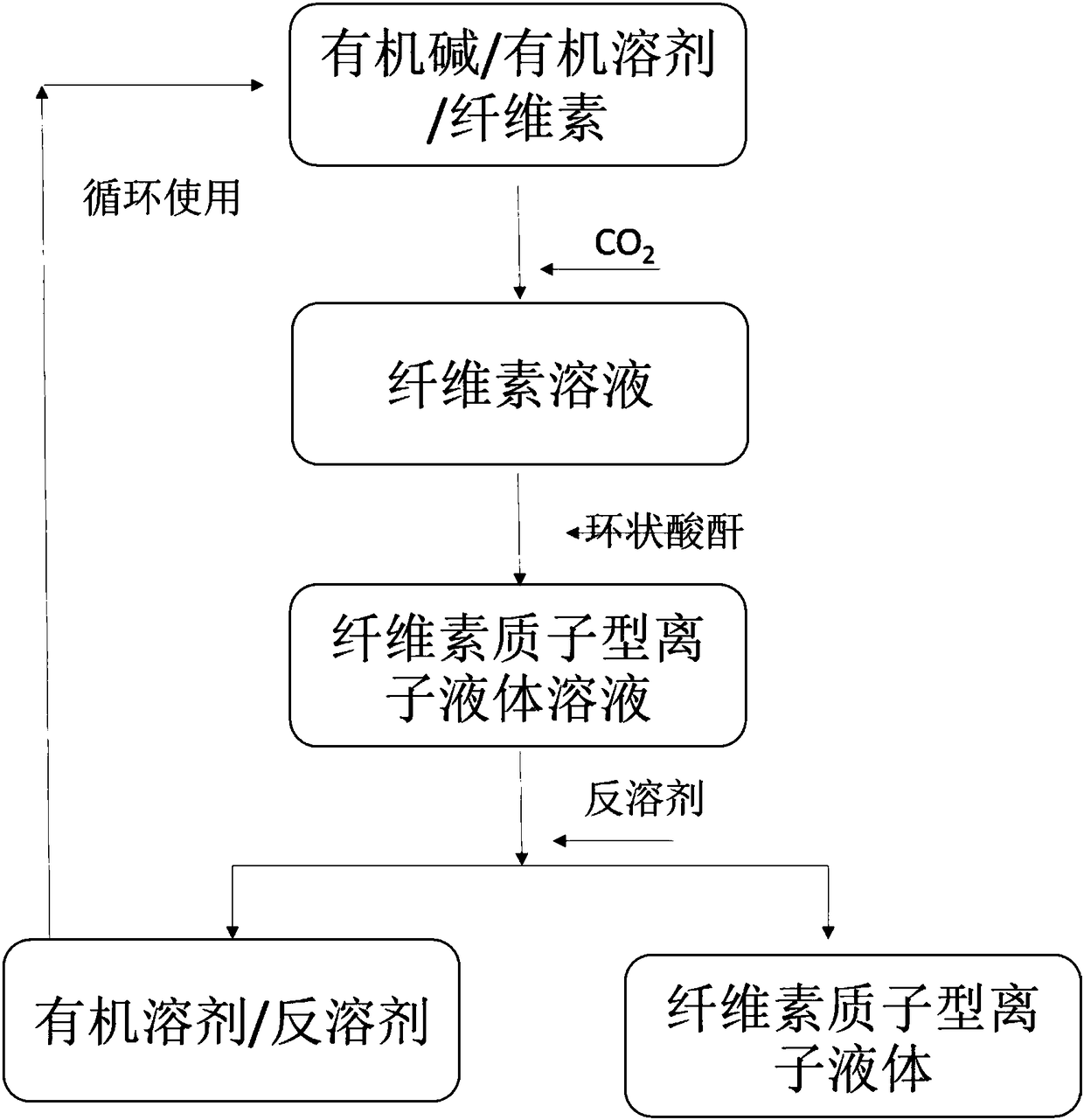

[0067] Embodiment 1 of the present invention: utilize cellulose to produce the method for cellulose proton type ionic liquid, comprise the steps:

[0068] 1) Use straw cellulose as cellulose, 1,8-diazabicyclo-bicyclo(5,4,0)-7-undecene (DBU) as organic base, and DMSO as aprotic polar Organic solvent, mix 2g cellulose, 2g organic base, and 10g aprotic polar organic solvent;

[0069] 2) Put the mixed system into the autoclave, cover the autoclave, and pass 0.2MPa of CO 2 , at a temperature of 80 °C, sealed with vigorous mechanical stirring for 6 hours, a one-pot reaction was performed to dissolve the cellulose. Obtain clear and transparent CO with cellulose base 2 Solutions of reversible polyionic compounds;

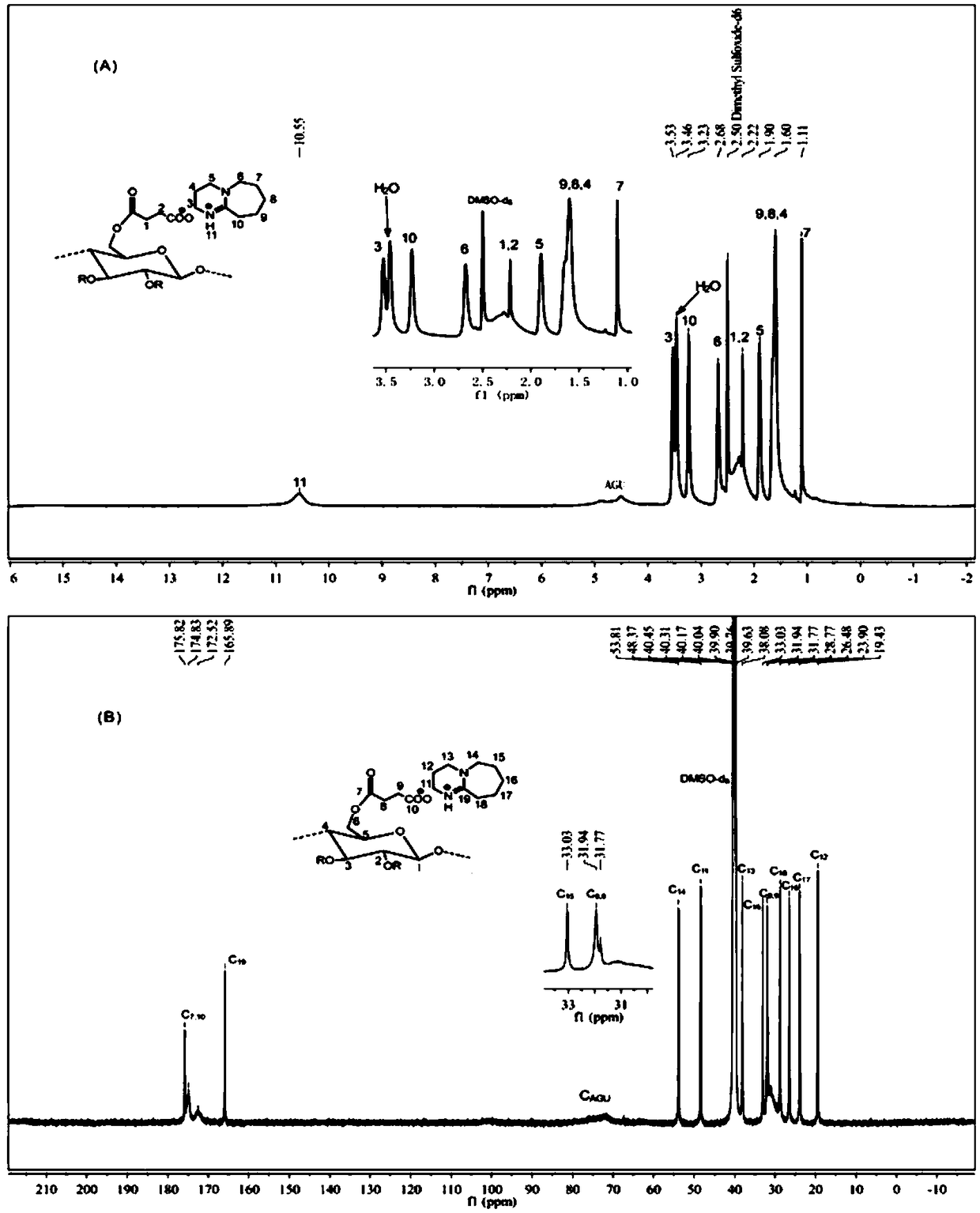

[0070] 3) Under a nitrogen atmosphere, lower the temperature of the reaction mixture to 40°C, add succinic anhydride to the cellulose solution at the same time, the molar ratio of succinic anhydride to cellulose hydroxyl is 1.2:1, raise the temperature to 50°C, Reacted ...

Embodiment 3

[0083] Embodiment 3 of the present invention: according to the step of embodiment 1, take by weighing about 0.6g of microcrystalline cellulose, 0.43g of tetramethylguanidine and about 9g of DMSO (the ratio of the molar number of tetramethylguanidine to the hydroxyl molar number in cellulose) The ratio is 1:1), put them into the autoclave together, cover the autoclave, and pass 0.4MPa of CO 2 , temperature at 40°C, sealed and vigorously mechanically stirred for 3 hours to carry out a one-pot reaction to dissolve cellulose. A clear and transparent cellulose solution was obtained, and the concentration of the cellulose solution was 5% (mass fraction). The temperature was raised to 50° C., and at the same time, 1.6 grams of maleic anhydride was added to the cellulose solution and reacted for 48 hours. After the reaction was completed, the product was precipitated with 4 times the amount of methanol, and vacuum-dried at room temperature for 24 hours.

[0084] The recovery of orga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com