A kind of production method of low odor coumarone resin

A technology of coumarone resin and production method, which is applied in the production of coumarone resin, the preparation of coumarone resin, and the preparation of low-odor coumarone resin, and can solve problems such as product environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

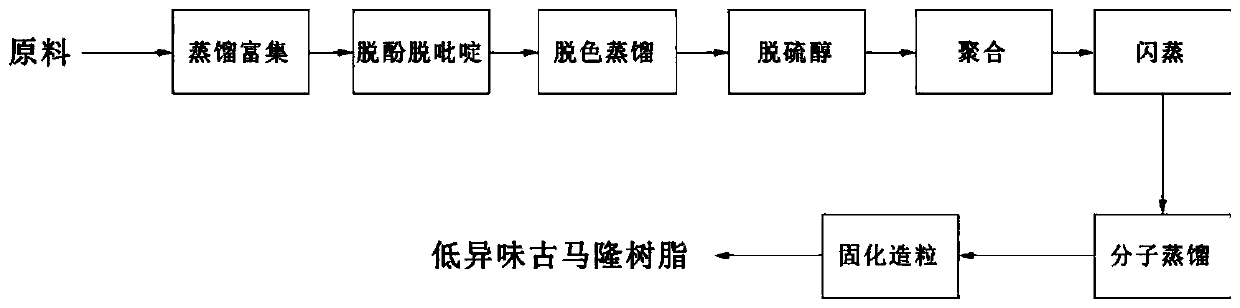

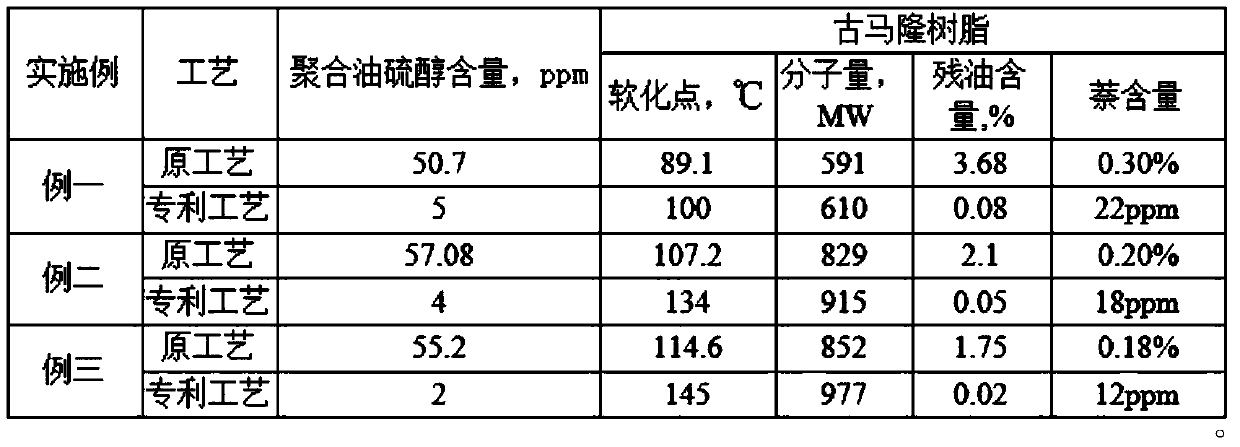

[0024] The key procedure of the method provided by the invention is: first the raw material (crude indene) is distilled, and the polymerizable components in the raw material (polymerizable components refer to active components that can be polymerized such as indene, methyl indene, styrene, etc.) , coumarone and other aromatics or olefins containing double bonds) for enrichment, while controlling the naphthalene content to less than 3%. Second: sweetening system; the sweetening tower is filled with activated carbon or molecular sieve, which can remove mercaptans, etc.; third, molecular distillation removes residual solvents of coumarone resin and oligomer resin.

[0025] The detailed technical plan includes the following steps:

[0026] 1) Raw material distillation: the raw material is cut through a distillation tower to obtain a fraction with a boiling point of 135-195° C. to obtain the crude coumarone fraction RCSN. Light and heavy oils are removed while enriching aggregatea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com