Preparation method of cleaning type bactericidal gelatin film

A gelatin film, cleaning technology, applied in the field of gelatin film preparation, can solve the problems of easy oil leakage, oxidative deterioration, moldy and other problems, and achieve the effect of sterilization, side effects, low toxicity and strong entanglement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

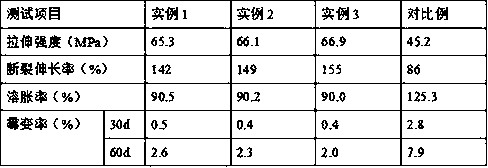

Examples

example 1

[0025] Take 100g Kochia scoparia, put it in a conical flask, add 300mL deionized water to the conical flask, and soak for 22 hours to obtain an impregnating liquid, put the impregnating liquid in an ultrasonic cleaner, start the cleaner, wash for 15 minutes, and wash repeatedly 2 times to obtain the Kochia scoparia medicinal liquid, filter the Kochia scoparia medicinal liquid with a non-woven fabric, remove the filter residue, obtain the filtrate, suction filter the filtrate, remove the residue, collect the extract, and transfer the extract to an evaporating dish , heat up to 45°C, evaporate and dry for 2 hours, and obtain liquid medicine powder; take 40g of dried grass carp scales and add them to a beaker filled with 400mL of sterile deionized water, heat the beaker in a water bath, and heat up to 35°C, then add 4g of trypsin Add it into a beaker, keep it warm for enzymolysis for 4 hours, filter and remove the filtrate to obtain enzymatic fish scales, wash the enzymatic fish s...

example 2

[0027] Take 115g of Kochia scoparia, put it in a conical flask, add 325mL of deionized water to the conical flask, and soak for 23 hours to obtain an impregnating liquid, put the impregnating liquid in an ultrasonic cleaner, start the cleaner, wash for 18 minutes, and wash repeatedly 3 times to obtain the Kochia scoparia medicinal liquid, filter the Kochia scoparia medicinal liquid with a non-woven fabric, remove the filter residue, obtain the filtrate, suction filter the filtrate, remove the residue, collect the extract, and transfer the extract to an evaporating dish , heat up to 48°C, evaporate and dry for 2.5 hours, and obtain liquid medicine powder; take 45g of dried grass carp fish scales and add them to a beaker filled with 425mL of sterile deionized water, heat the beaker in a water bath, and heat up to 38°C, then add 4.5g Add trypsin into a beaker, keep it warm for 4.5 hours, filter and remove the filtrate to obtain enzymatic fish scales, wash the enzymatic fish scales...

example 3

[0029] Take 120g Kochia scoparia, put it in a conical flask, add 350mL deionized water to the conical flask, and soak for 24 hours to obtain an impregnating liquid, put the impregnating liquid in an ultrasonic cleaner, start the cleaner, wash for 20 minutes, and wash repeatedly 4 times to obtain the Kochia scoparia medicinal liquid, filter the Kochia scoparia medicinal liquid with a non-woven fabric, remove the filter residue, obtain the filtrate, suction filter the filtrate, remove the residue, collect the extract, and transfer the extract to an evaporating dish , heat up to 50°C, evaporate and dry for 3 hours, and obtain liquid medicine powder; take 50g of dried grass carp scales and add them to a beaker filled with 450mL of sterile deionized water, heat the beaker in a water bath, and heat up to 40°C, then add 5g of trypsin Put it into a beaker, heat it for enzymatic hydrolysis for 5 hours, filter and remove the filtrate to obtain enzymatic fish scales, wash the enzymatic fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com