Epitaxial growth method of silicon substrate GaN-based LED

A technology of epitaxial growth and silicon substrate, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of epitaxial wafer cracking, large epitaxial layer, large lattice mismatch, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to allow those skilled in the art to understand the present invention more clearly and intuitively, the present invention will be further described below.

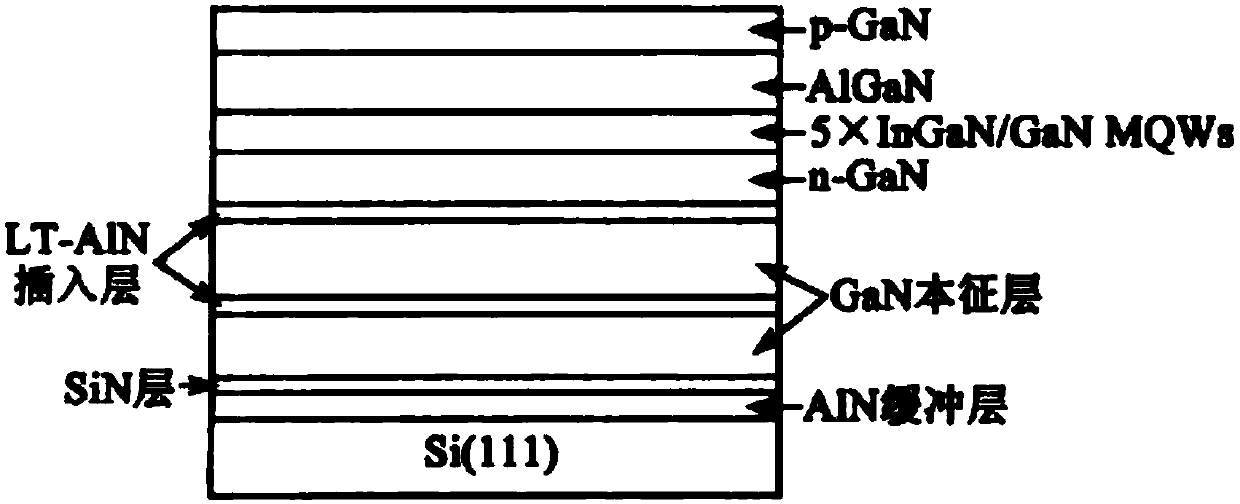

[0014] A GaN-based LED epitaxial growth method on a silicon substrate, using Thomas Swan's LP-MOCVD system, using Si(111) as the substrate, trimethylgallium (TMGa), trimethylaluminum (TMAl), trimethylindium (TMIn) and high-purity NH3 are Ga, Al, In and N sources respectively, H2 and N2 are carrier gases, silane (SiH 4 ) and Magnesium (CP 2 Mg) are n-type and p-type dopants respectively; the Si substrate should be cleaned before growth to remove pollutants and impurities to obtain a clean surface;

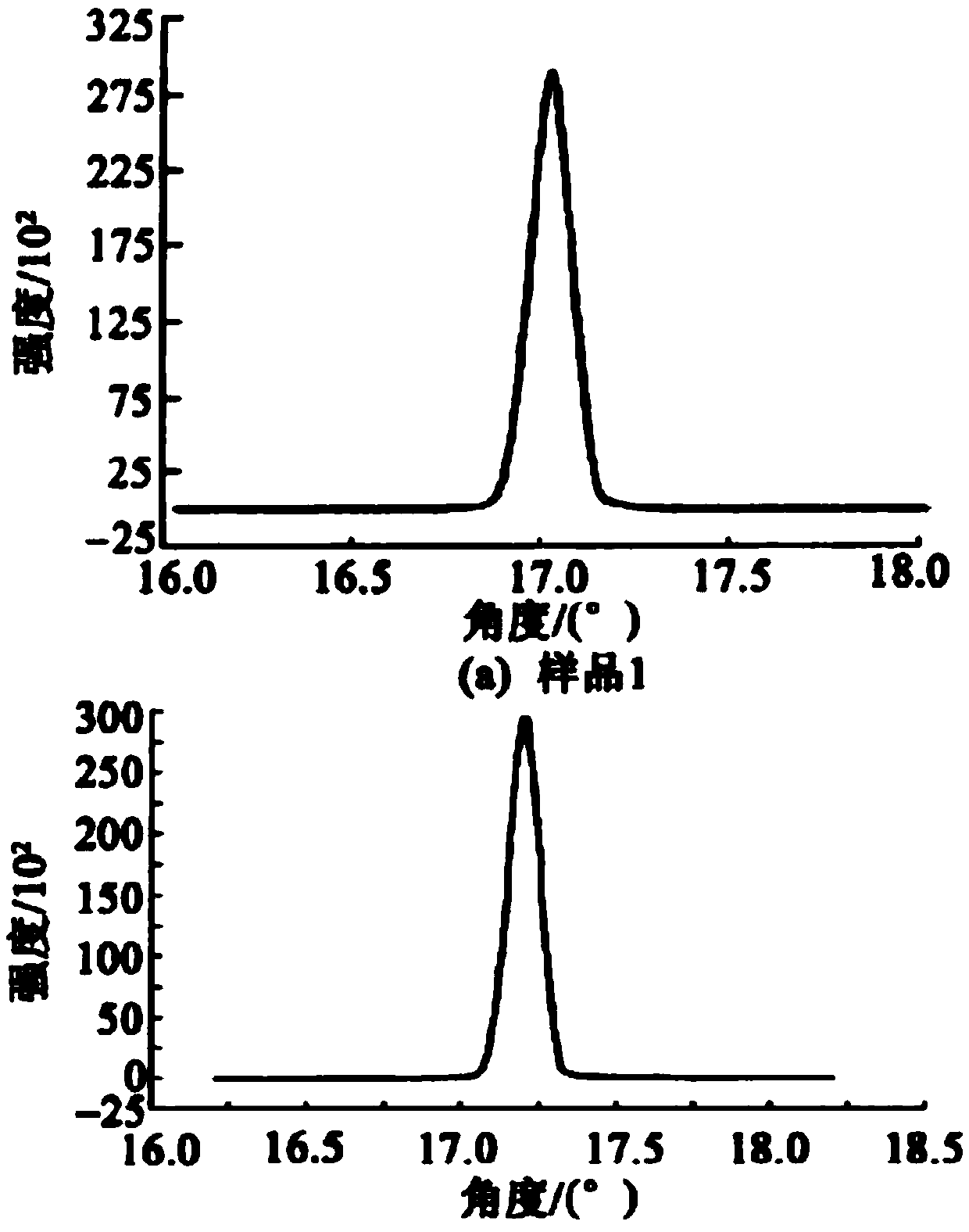

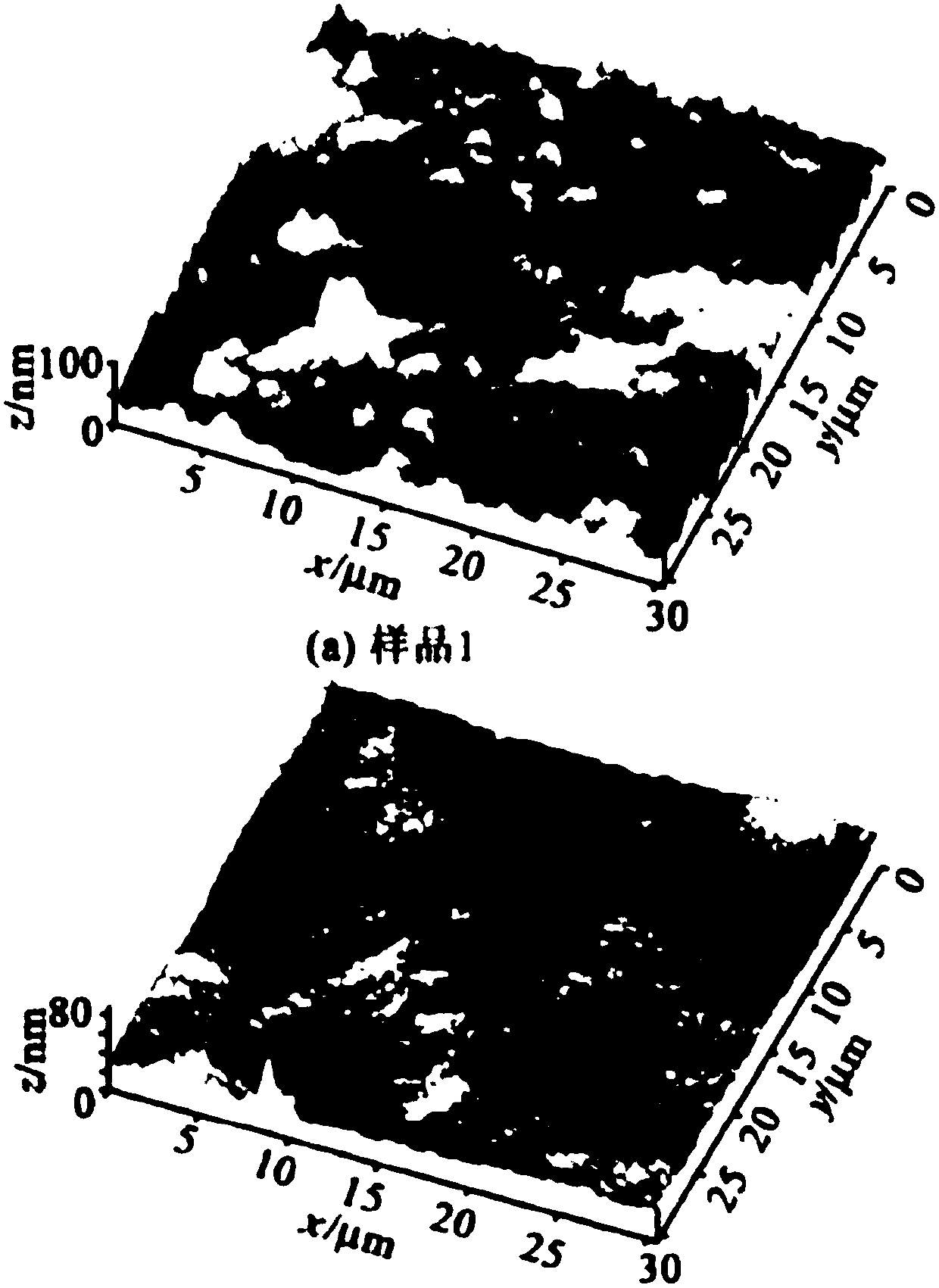

[0015] The epitaxial growth process is as follows: Sample 1 was first grown at 1100 °C, H 2 Hydrogenation under the atmosphere for 10min to clean the surface of the silicon wafer; after hydrogenation treatment, the temperature was lowered to 1060°C to grow the AlN buffer layer and the high-temperature GaN layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com