Preparation method of porous nano-optical fiber heterostructure photocatalysis filter net

A heterostructure, nano-fiber technology, applied in the field of nanomaterials, can solve the problems of low ability of filter screen to adsorb organic pollutants, low catalytic efficiency of photocatalytic materials, inability to make full use of sunlight, etc., so as to increase the specific surface area of photocatalysis, Small size, the effect of increasing size and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

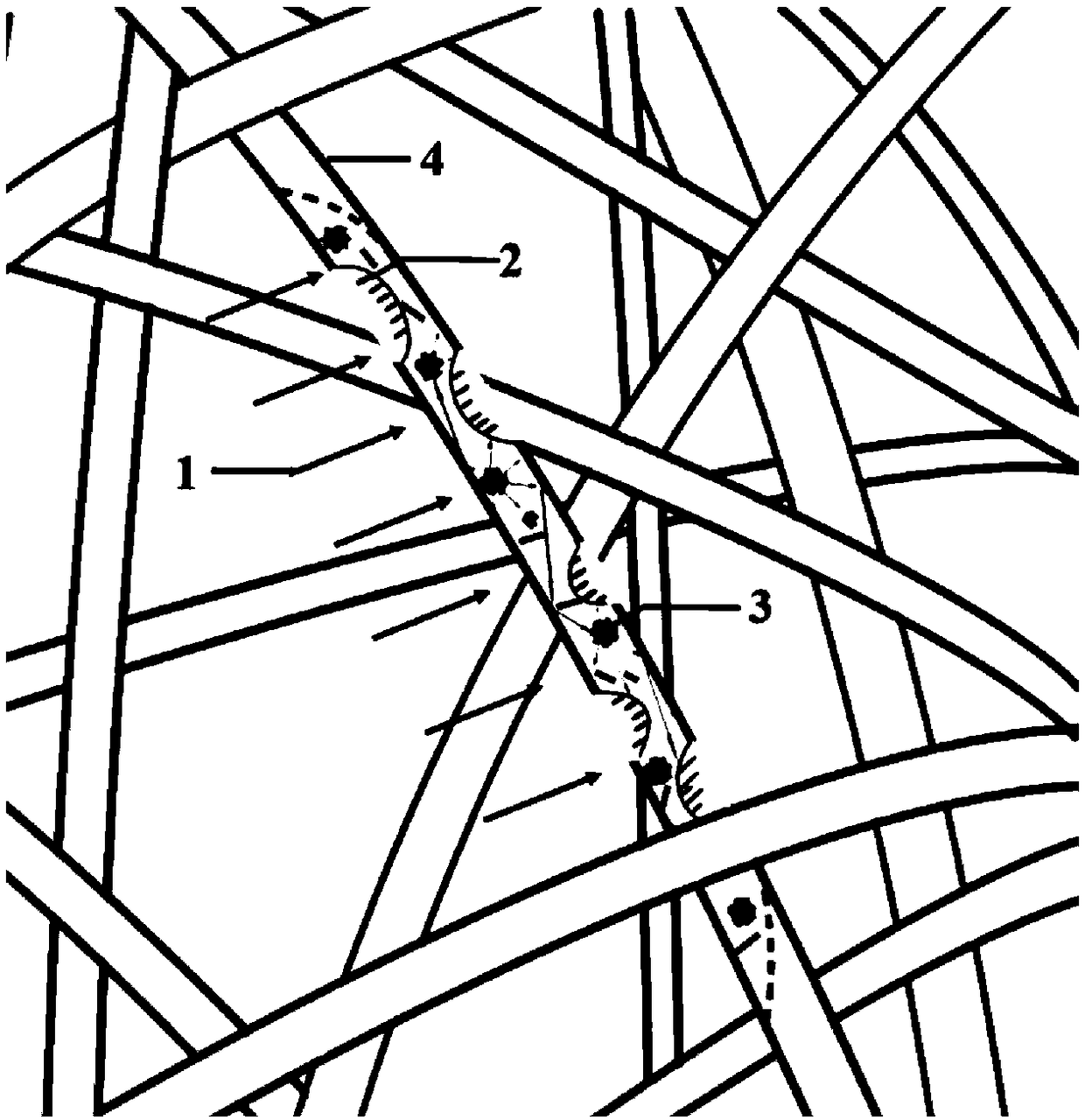

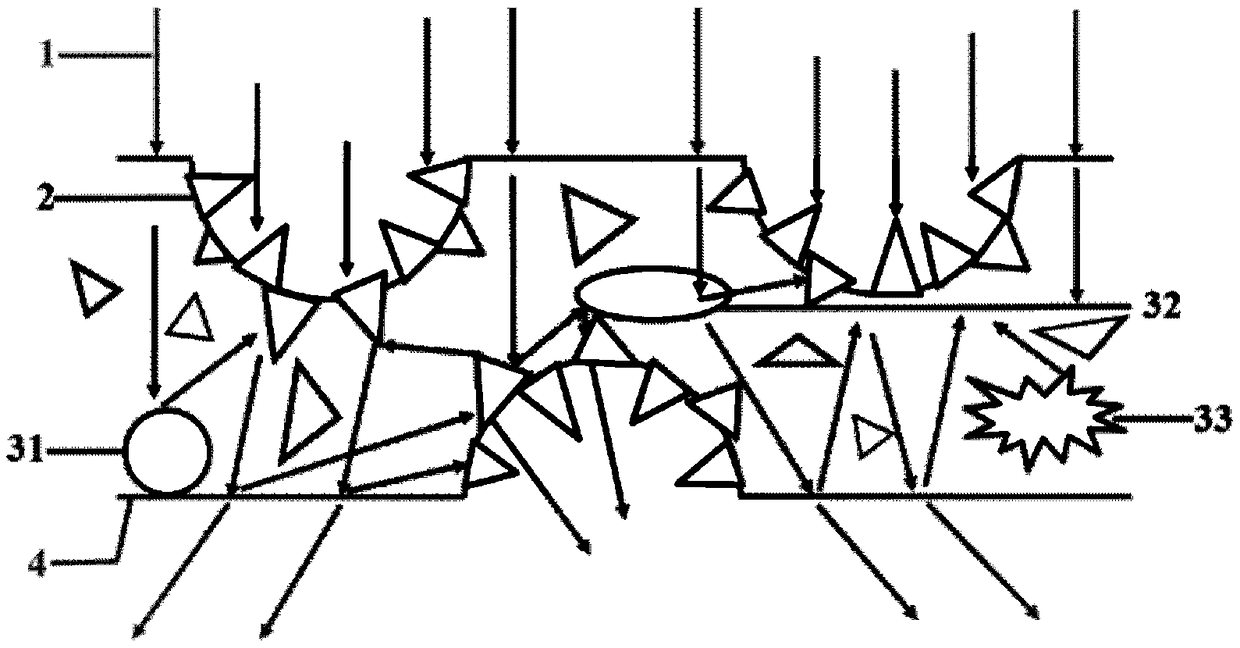

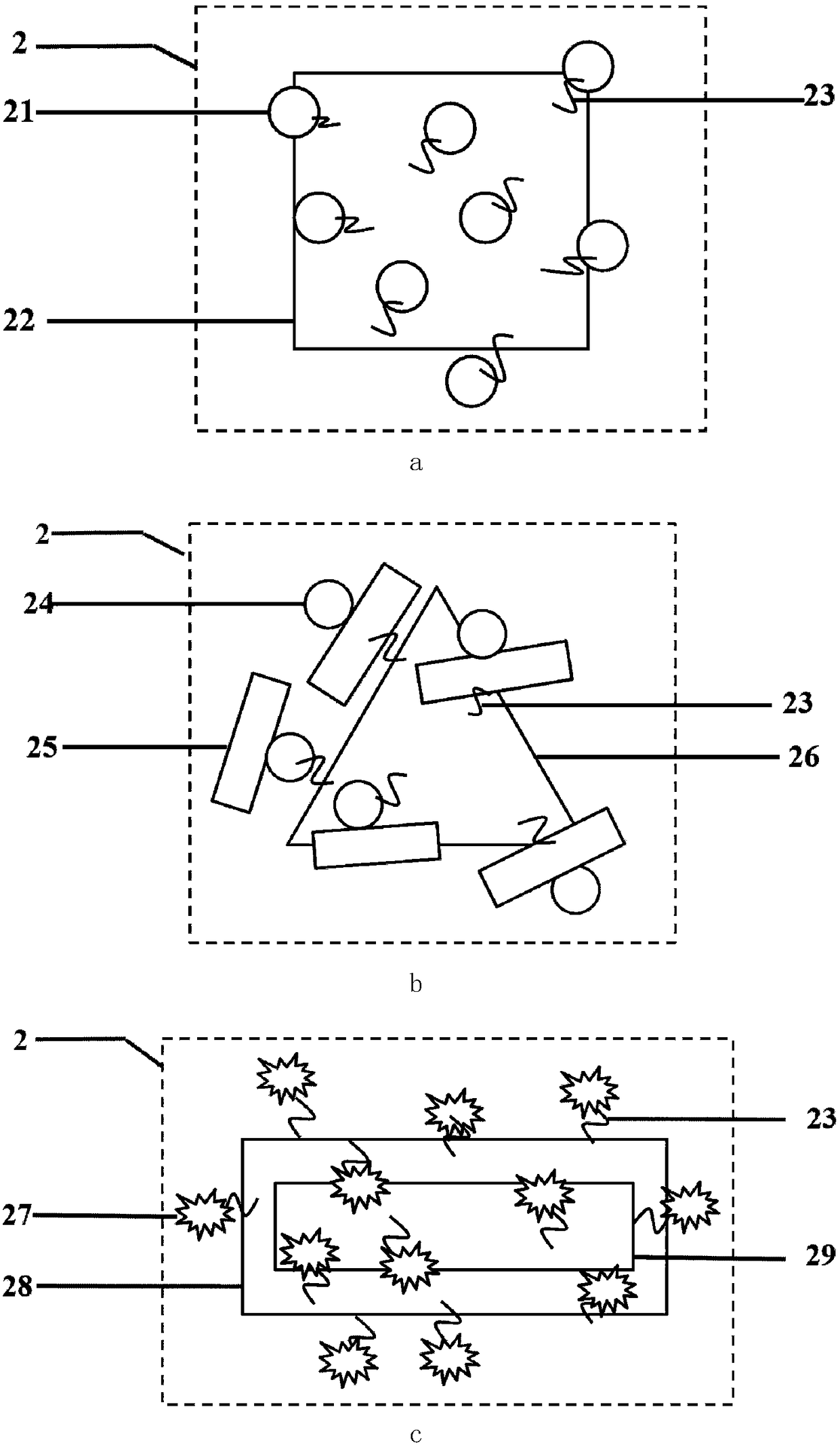

[0032] Step 1: Preparation of photocatalytic heterostructures composed of plasmonic metal nanostructures and semiconductor nanostructures with tunable spectra from visible to infrared bands

[0033] The gold nanocubes with tunable spectra in the visible to infrared bands were centrifuged three times at 4500 rpm for 15 min, the precipitate was dissolved in deionized water, and an initial solution a with a concentration of 0.1 mol / L was prepared. Centrifuge the cadmium sulfide nanosphere solution at 10,000rpm for 20min five times, dissolve the precipitate in deionized water, and configure it as an initial solution b with a concentration of 3mol / L; dissolve polyethylene glycol molecules in deionized water, and configure it with a concentration of 6mol / L initial solution c; take 20ml each of initial solution b and initial solution c, mix well, then centrifuge 3 times at 5000rpm for 15min, and dissolve the precipitate in deionized water to obtain a mixed solution d with a concentra...

specific Embodiment 2

[0039] Step 1: Preparation of photocatalytic heterostructures composed of plasmonic metal nanostructures and semiconductor nanostructures with tunable spectra from visible to infrared bands

[0040] Centrifuge the silver triangle solution with adjustable spectrum from visible to infrared band at 6000rpm for 25min twice, dissolve the precipitate in deionized water, and prepare initial solution a with a concentration of 0.5mol / L. The heterostructure solution composed of titanium dioxide nanorods and silver nanospheres was centrifuged three times at 8000rpm for 10min, and the precipitate was dissolved in deionized water to form an initial solution b with a concentration of 1mol / L; dimercapto-polyethylene glycol molecules Dissolve in deionized water and configure initial solution c with a concentration of 1mol / L; mix 20ml of initial solution b and initial solution c, stir thoroughly, then centrifuge 3 times at 6000rpm for 15min, and dissolve the precipitate in deionized water to ob...

specific Embodiment 3

[0046] Step 1: Preparation of photocatalytic heterostructures composed of plasmonic metal nanostructures and semiconductor nanostructures with tunable spectra from visible to infrared bands

[0047] Centrifuge the gold-silver alloy nanorod solution with adjustable spectrum from visible to infrared bands at 8000rpm for 15min three times, dissolve the precipitate in deionized water, and prepare initial solution a with a concentration of 2mol / L. Centrifuge the zinc oxide nanostar solution twice at 10,000rpm for 5min, dissolve the precipitate in deionized water, and configure the initial solution b with a concentration of 5mol / L; dissolve 3-aminopropyl triethoxy silicon in deionized water, Prepare the initial solution c with a concentration of 8mol / L; take 20ml each of the initial solution b and the initial solution c, mix them thoroughly, then centrifuge 3 times at 3000rpm and 10min, and dissolve the precipitate in deionized water to obtain a concentration of 5mol / L. mixed soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com