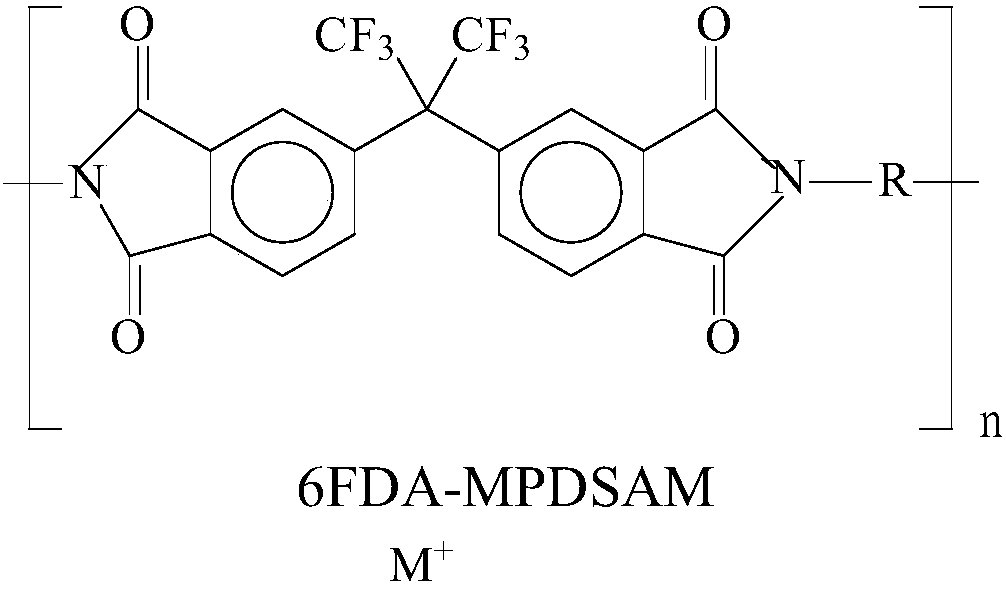

Polyimide gas separation membrane material, and preparation and application thereof

A technology of gas separation membrane and polyimide, which is applied in the field of polyimide polymer, can solve the problems of unrelated separation performance and low selectivity, and achieve the effect of good solubility and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

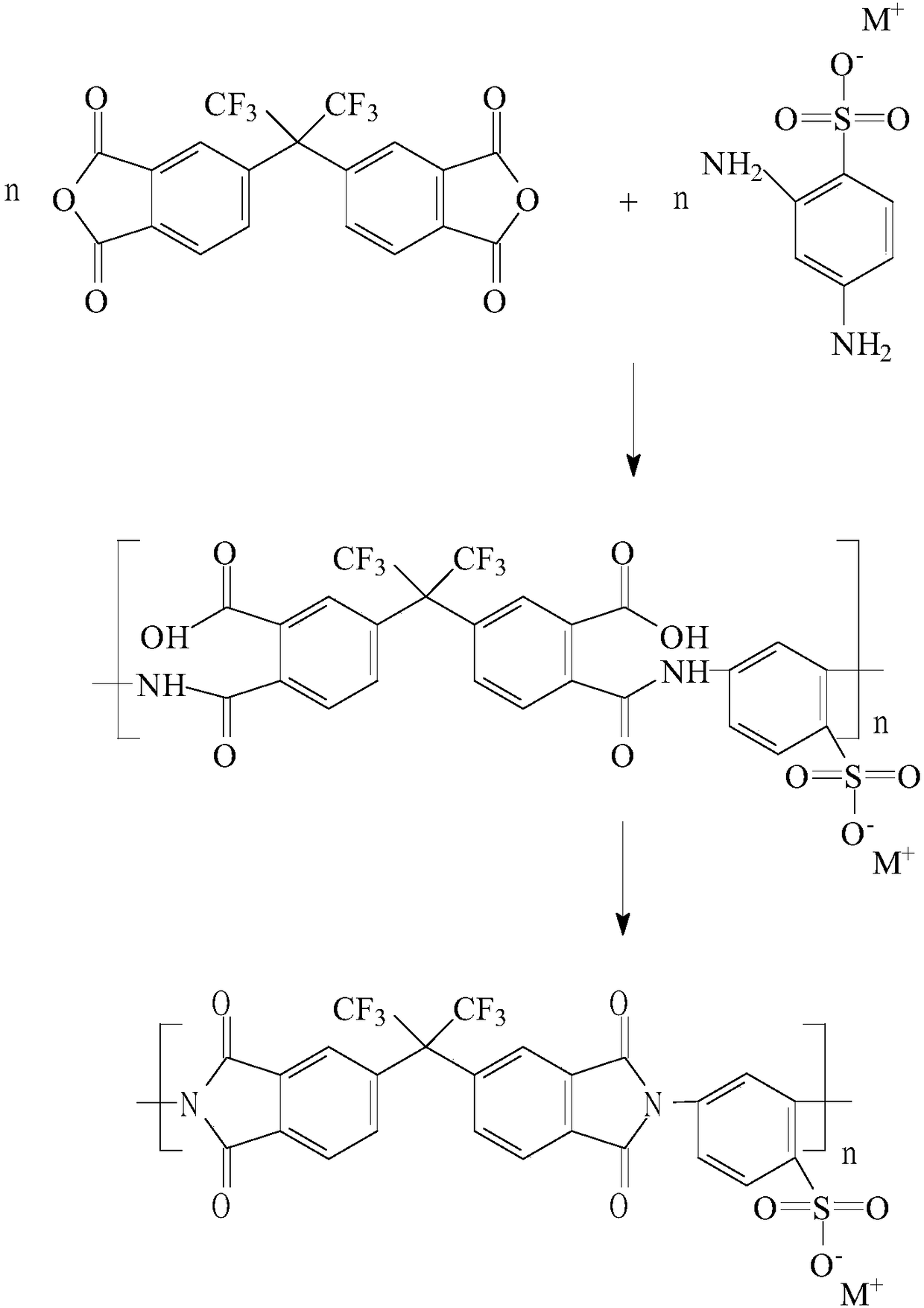

Method used

Image

Examples

Embodiment

[0027] Place a 100mL four-necked round-bottomed flask with mechanical stirring, nitrogen inlet and outlet, and a thermometer in a constant temperature water bath. Dissolve 0.01 mol of diamine monomer MPDSALi salt in 20 mL of NMP. Then 0.01 molar 6FDA was added together with another 20 mL of NMP. The solution was stirred at room temperature for 24 hours to form a viscous polyamic acid solution; then 0.05 mole of acetic anhydride and 0.05 mole of triethylamine were added for imidization, and the polymer was allowed to settle in methanol after reacting for 20 hours at room temperature. It was washed three times with methanol, filtered, air-dried at room temperature for 1 hour, and then dried in a vacuum oven at 100-250° C. for 24 hours. After the oven is naturally cooled to room temperature, the polymer film is taken out.

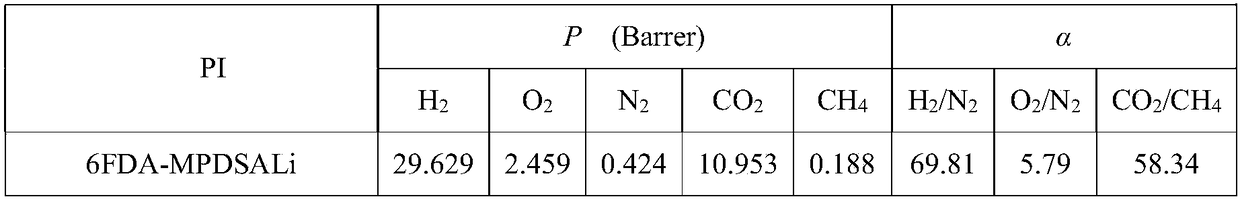

[0028] The polyimide 6FDA-MPDSALi prepared above was dissolved in NMP at room temperature to form a 10% (mass content) solution, and the solution was filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com