Lithium-sulfur battery electrode and preparation method thereof, and lithium-sulfur battery structure containing lithium-sulfur battery electrode

A lithium-sulfur battery and electrode technology, applied in battery electrodes, lithium storage batteries, structural parts, etc., can solve the problems of discontinuous conductive network inside the electrode, low utilization rate of active materials, peeling of active materials, etc., and improve the utilization rate of active materials. and cycle life, achieving large-scale production, and the effect of mild experimental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Dissolve 2g of binder PVDF-HFP in 40g of N-methylpyrrolidone (NMP), stir for 1h, add 4g of S / A-KB600 (sulfur-filling 75%), stir for 4h, adjust the scraper to 300μm, and place on a glass plate Squeegee coating on the top to form a film (no metal film is used as a current collector), and then quickly immerse the glass plate and the electrode coating on the top of the scrape in water. After 10 minutes, the electrode coating falls off on the glass plate and is taken out. Dry overnight at 65°C Finally, the activation pretreatment solution is used as the electrolyte, the electrode substrate and the nickel sheet are used as the negative electrode and the positive electrode respectively, and the surface area relative to the electrode substrate is 10mA / cm 2 Activation at current density for 4 minutes. The composition of the activation pretreatment solution is a hydrochloric acid aqueous solution with a concentration of 240g / L nickel chloride at PH=3; the electrode substrate afte...

Embodiment 2

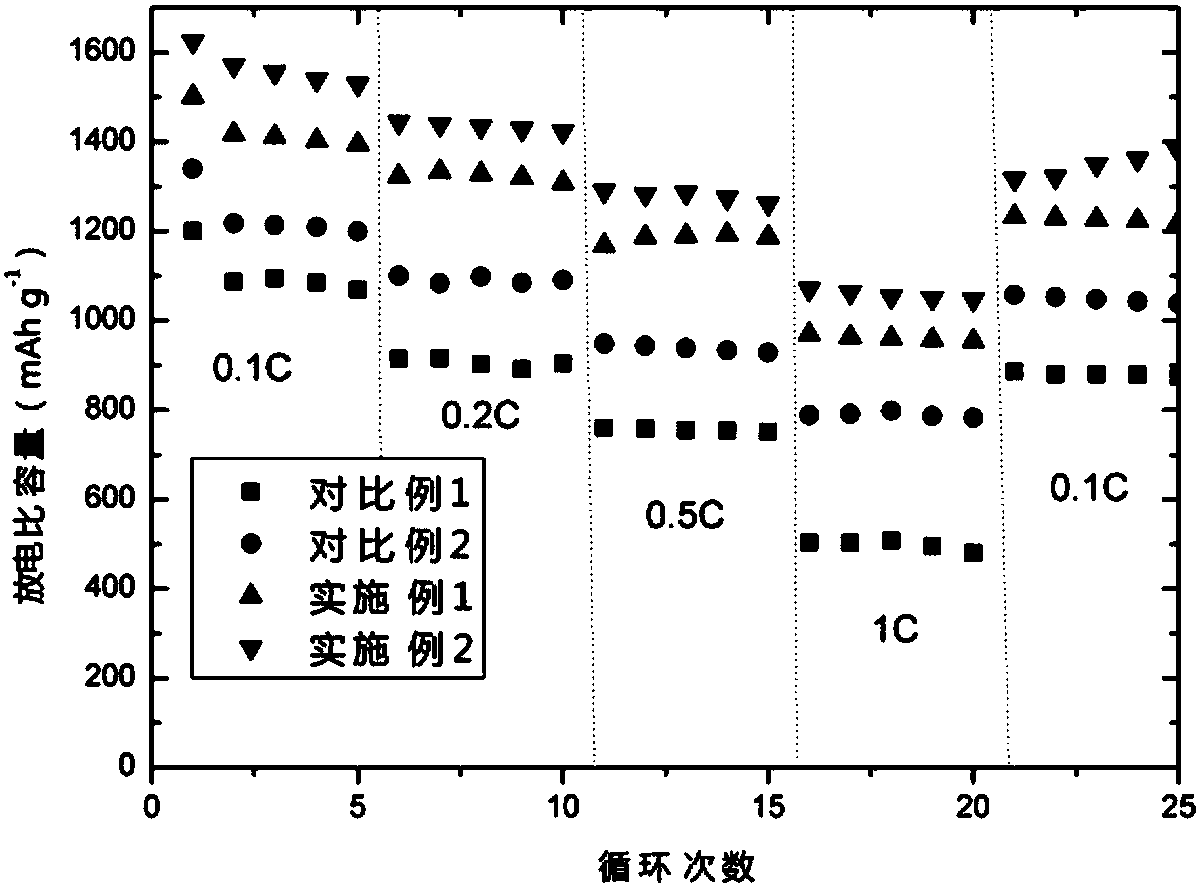

[0037] Electrode matrix preparation and electroless plating modification operation process is the same as that of Example 1, the parameters of modulation are electroless plating time is 50 minutes, the thickness of the nickel layer deposited on the electrode surface is about 1.0 μm, and the assembled battery is operated at a rate of 0.1C. Cycle performance test, rate performance test at 0.1C-1C rate.

[0038] The specific capacity of the first cycle discharge is 1625mAh g -1 , the capacity maintained at 1124mAh g after 100 cycles -1 ; When the rate is increased to 1C, the specific discharge capacity is 1070mAh g -1 .

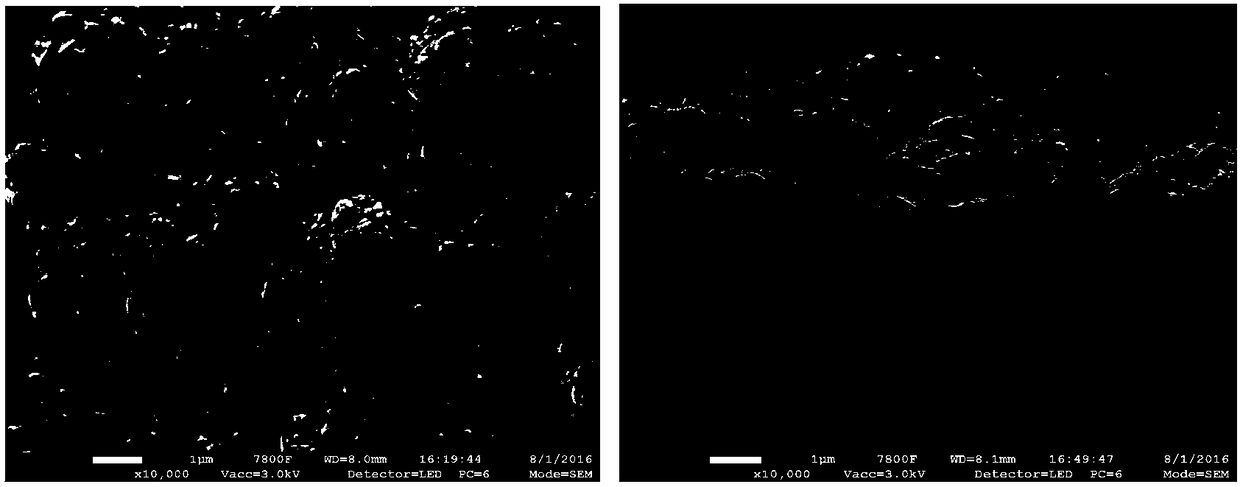

[0039] Depend on figure 1 As shown, the lithium-sulfur cathode material modified by electroless Ni plating will deposit a layer of nickel layer with metallic luster on its surface, which has the effect of inhibiting polysulfide shuttles. figure 2 As shown, the surface of the nickel layer is dense, and its plating layer is uniformly deposited on the electrod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com