Preparation method of high-strength bacteria-inhibiting medical gauze

A high-strength, gauze technology, applied in medical science, biochemical fiber treatment, absorbent pads, etc., can solve problems such as low strength and poor antibacterial properties, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

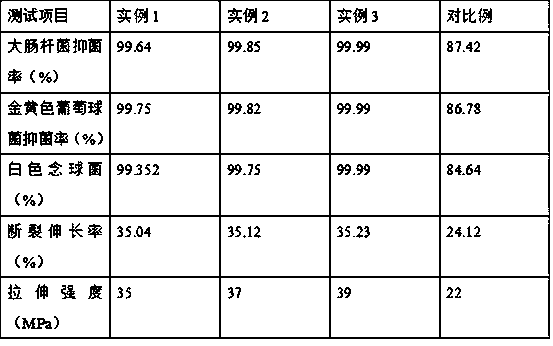

Examples

example 1

[0026]Take by weighing 30g of silkworm chrysalis shells and put them into a beaker with 60mL mass fraction of 10% hydrochloric acid solution, mix and soak for 1 day at a temperature of 25°C, then add 90mL mass fraction of 30% sodium hydroxide solution into the beaker, Continue mixing and immersion at a temperature of 80°C for 1 hour to obtain the alkali-washed substance, and rinse the alkali-washed substance with 15% hydrogen peroxide for 3 times, control the pH value of the alkali-washed substance to 10, and remove the deacetylated carapace after washing Home-made chitosan; according to the mass ratio of 1:2:1, the home-made chitosan, glacial acetic acid solution with a mass fraction of 98% and polyvinyl alcohol were mixed and stirred for 45 minutes to obtain a modified home-made chitosan solution. The modified self-made chitosan solution is transported to the porous leaking plate, and the wire is drawn at a speed of 1500r / min to obtain the modified self-made chitosan fiber; t...

example 2

[0028] Take by weighing 35g silkworm chrysalis shells and put them into a beaker with 70mL mass fraction of 10% hydrochloric acid solution, mix and soak for 1 day at a temperature of 30°C, then add 100mL mass fraction of 30% sodium hydroxide solution to the beaker, Continue mixing and immersion at a temperature of 85°C for 1.5h to obtain the alkali-washed substance, and rinse the alkali-washed substance with 15% hydrogen peroxide for 4 times, control the pH value of the alkali-washed substance to 11, and remove the deacetylated substance after rinsing. Chitin is self-made chitosan; according to the mass ratio of 1:2:1, the self-made chitosan, glacial acetic acid solution with a mass fraction of 98% and polyvinyl alcohol were mixed and stirred for 50 minutes to obtain a modified self-made chitosan solution , the modified self-made chitosan solution is transported to the porous leaking plate, and the wire is drawn at a speed of 1700r / min to obtain the modified self-made chitosan ...

example 3

[0030] Take by weighing 40g silkworm chrysalis shells and put them into a beaker with 80mL mass fraction of 10% hydrochloric acid solution, mix and soak for 2 days at a temperature of 35°C, then add 110mL mass fraction of 30% sodium hydroxide solution to the beaker, Continue mixing and soaking at a temperature of 90°C for 2 hours to obtain the alkali-washed substance, and rinse the alkali-washed substance with 15% hydrogen peroxide for 5 times, control the pH value of the alkali-washed substance to 12, and remove the deacetylated carapace after washing Home-made chitosan; according to the mass ratio of 1:2:1, the home-made chitosan, glacial acetic acid solution with a mass fraction of 98% and polyvinyl alcohol were mixed and stirred for 60 minutes to obtain a modified home-made chitosan solution. The modified self-made chitosan solution was transported to the porous leaking plate, and the wire was drawn at a speed of 2000r / min to obtain the modified self-made chitosan fiber; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com