Microgroove group radiator

A technology of micro-grooves and radiators, which is applied to electric solid devices, semiconductor devices, and semiconductor/solid-state device components, etc., can solve the problems of heat transfer deterioration, drying of liquid working medium, etc. Improves wetting length and optimizes liquid film distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

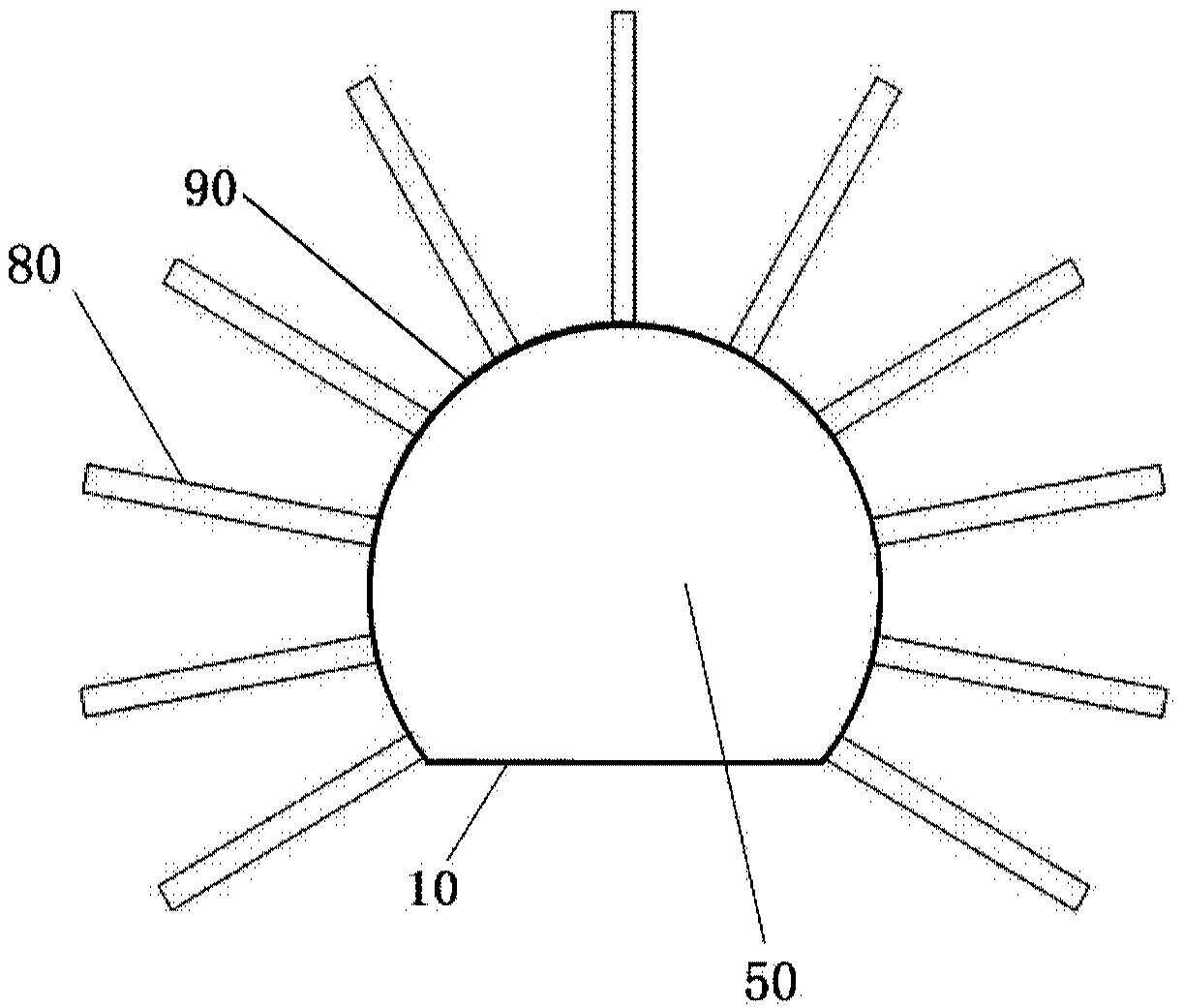

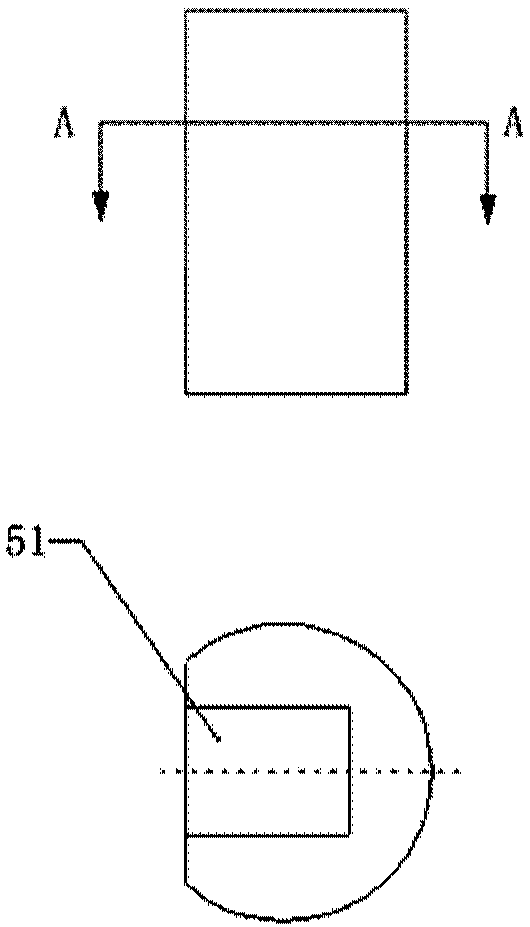

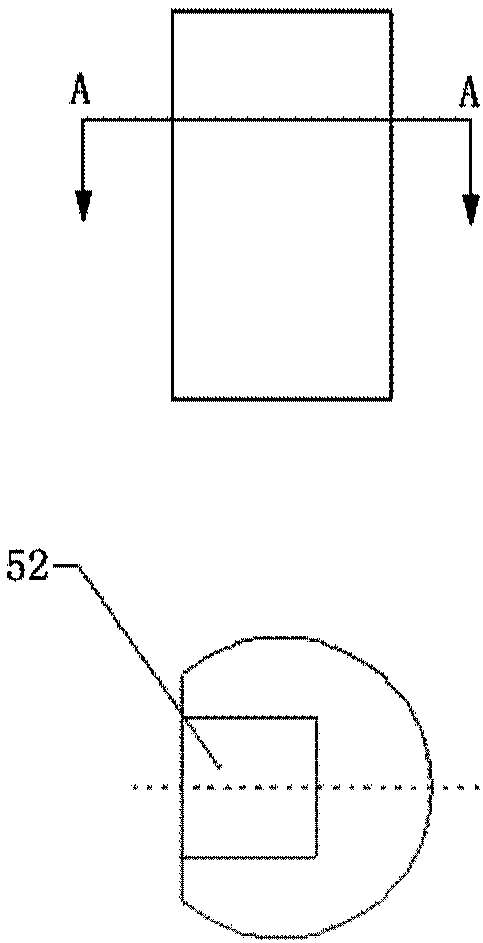

[0058] The disclosure provides a micro-groove group radiator, which includes a micro-nano composite structure surface heat sink heat-taking surface and a heat-dissipating surface, wherein the micro-nano composite structure surface heat sink has a hydrophilic nano-coating; the heat-taking surface and the heat dissipation surface The surface forms a closed cavity, which contains a liquid working medium. In the cavity, a high-voltage electric field is applied to the surface heat sink of the micro-nano composite structure to form an EHD effect. The ultra-high surface energy of the hydrophilic nano-coating on the surface of the micro-nano composite structure of the micro-groove group radiator of the present disclosure strengthens the surface energy and roughness of the liquid working medium in the micro-channel, and improves the surface wetting characteristics , the electric field exerts directional traction on the liquid working medium, increases the mass flow rate of the liquid wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com