Clean production method of co-precipitation process positive material carbonate precursor

A cathode material and co-precipitation technology, which is applied in the field of clean production of carbonate precursors of cathode materials in co-precipitation method, can solve the problem of high product yield, achieve simple operation, simple production process and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

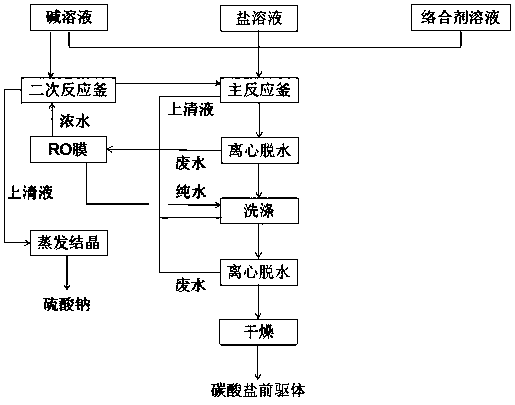

[0025] like figure 1 As shown, a clean production method for a carbonate precursor of a positive electrode material by a co-precipitation method includes the following steps:

[0026] 1) Use deionized water to prepare 1 mol / L nickel sulfate, cobalt sulfate and manganese sulfate mixed salt solution, 1 mol / L sodium carbonate solution and 0.25 mol / L ammonia solution, respectively, and add them to the main reactor at a certain rate, The pH value of the main reactor is controlled at about 7.8, and the co-precipitation reaction is carried out by stirring in a constant temperature water bath at 60°C;

[0027] 2) After the solid precipitation product of the main reactor in the above step 1) is subjected to 3 centrifugal dehydration and 2 washing with water, the sodium sulfate content of the waste water is 320 ppm, and then drying treatment is performed to obtain the positive electrode material carbonate precursor. ;

[0028] 3) The supernatant of the main reactor in the above step 1...

Embodiment 2

[0032] A clean production method for a co-precipitation cathode material carbonate precursor, comprising the following steps:

[0033] 1) Use deionized water to prepare 2.5mol / L nickel sulfate, cobalt sulfate and manganese sulfate mixed salt solution, 2.5mol / L sodium carbonate solution and 0.45mol / L ammonia solution, and add them to the main reaction at a certain rate. The pH value of the main reaction kettle is controlled at about 8.4, and the co-precipitation reaction is carried out by stirring in a constant temperature water bath at 60 °C;

[0034] 2) After the solid precipitation product of the main reactor in the above step 1) is subjected to 5 times of centrifugal dehydration and 4 times of washing with water, the sodium sulfate content of the waste water is 480ppm, and then drying treatment is performed to obtain the positive electrode material carbonate precursor. ;

[0035] 3) The supernatant of the main reactor in the above step 1) and the waste water after centrifu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com