Si@C composite anode material and preparation method thereof

A negative electrode material, silicon-carbon composite technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor conductivity and high expansion rate, so as to facilitate absorption and storage, improve circulation, and increase lithium ion production capacity. The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

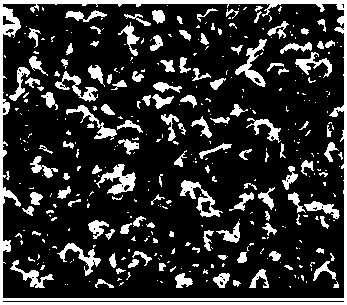

Image

Examples

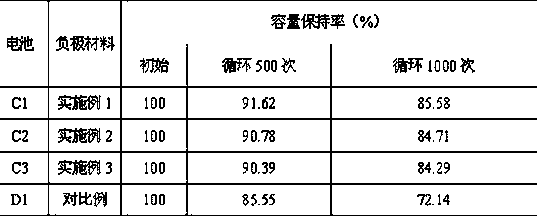

Embodiment 1

[0015] Step ①Lithium metaaluminate solution configuration:

[0016] Weigh 5g of lithium metaaluminate, 5g of graphene, and 15g of polyvinylidene fluoride, add them to 150ml of N-methylpyrrolidone, stir evenly, and disperse for 3 hours through a high-speed disperser to finally obtain a lithium metaaluminate solution.

[0017] Step ② Spherical SiO 2 Precursor preparation:

[0018] Under magnetic stirring, add 100ml ethanol, 6mL H 2 O, 0.6mL NH 3 •H 2 Slowly add 3mL tetraethylorthosilicate (TEOS) dropwise to the mixed liquid of O, stir for 5h, centrifuge, wash and dry for later use to obtain spherical SiO 2 The precursor is spherical silica powder.

[0019] Step ③ SiO 2 Preparation of @C balls:

[0020] 0.6g of spherical SiO 2 The precursor was evenly mixed with 0.1 g of polyvinylidene fluoride PVDF powder and dispersed in 6 mL of N-methylpyrrolidone (NMP), then dried in an oven at 120 °C for 2 h under vacuum, and then the dried sample was placed in a tube furnace , ...

Embodiment 2

[0024] Step ① Lithium metaaluminate configuration:

[0025] Weigh 1 g of lithium metaaluminate, 1 g of graphene, and 10 g of polyvinylidene fluoride, add them to 100 ml of N-methylpyrrolidone, and disperse uniformly at high speed for 3 hours to obtain a lithium metaaluminate solution.

[0026] Step ② Spherical SiO 2 Precursor preparation:

[0027] Under magnetic stirring, add 100ml ethanol, 6mL H 2 O, 0.6mL NH 3 •H 2 Slowly add 1.0mL tetraethyl orthosilicate (TEOS) dropwise to the mixed liquid of O, stir for 5h, centrifuge, wash and dry for later use to obtain spherical SiO 2 The precursor is spherical silica powder.

[0028] Step ③ SiO 2 Preparation of @C balls:

[0029] 0.2 g of spherical SiO 2 The precursor was evenly mixed with 0.05 g of polyvinylidene fluoride PVDF powder and dispersed in 6 mL of N-methylpyrrolidone (NMP), then vacuum-dried in an oven at 120 °C for 2 h, and then the dried sample was placed in a tube furnace , and calcined at 400°C for 3h unde...

Embodiment 3

[0033] Step ① Preparation of lithium metaaluminate solution: Weigh 10 g of lithium metaaluminate, 10 g of graphene, and 20 g of polyvinylidene fluoride, add them to 200 ml of N-methylpyrrolidone, and disperse uniformly at high speed for 3 hours to obtain a lithium metaaluminate solution.

[0034] Step ② Spherical SiO 2 Precursor preparation:

[0035] Under magnetic stirring, add 100ml ethanol, 6mL H 2 O, 0.6mL NH 3 •H 2 Slowly add 5mL tetraethylorthosilicate (TEOS) dropwise to the mixed liquid of O, stir for 5h, centrifuge, wash and dry for later use to obtain spherical SiO 2 The precursor is spherical silica powder.

[0036] Step ③ SiO 2 Preparation of @C balls:

[0037] 0.8 g of spherical SiO 2 The precursor was mixed evenly with 0.2g of polyvinylidene fluoride PVDF powder and dispersed in 6mL of N-methylpyrrolidone (NMP), then vacuum-dried in an oven at 120°C for 2h, and then the dried sample was placed in a tube furnace , and calcined at 600°C for 3h under a ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com