Graphite lithium ion battery negative electrode material with multiple layers of graphene surfaces and preparation method thereof

A multi-layer graphene and lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as poor temperature controllability, low safety factor, and large material consumption, and achieve easy diffusion and lithium storage capacity Large, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

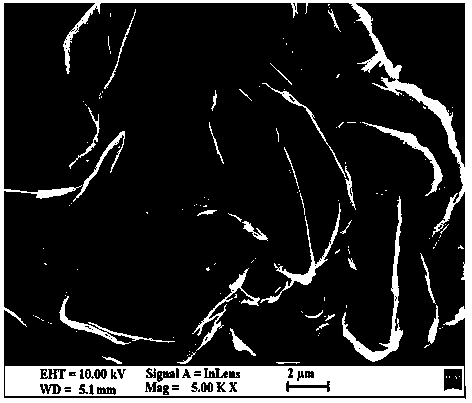

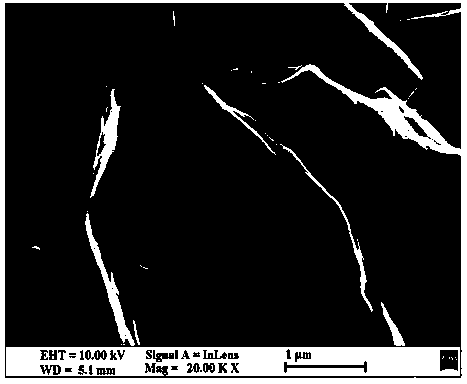

Image

Examples

Embodiment 1

[0028] A preparation method of a graphite lithium-ion battery negative electrode material with multilayer graphene on the surface, comprising the following steps:

[0029] (1) Take 0.5g of graphite samples and 8.42g of KNO in the particle size range of 10~50μm 3 , ball milled for 30 minutes until uniform without graininess, then weighed 12g of mixed salt a and continued ball milling evenly. The obtained mixture was sintered in a tube furnace at 360°C with a heating rate of 2°C / min for 6~12h in an air atmosphere, cooled to room temperature naturally, the obtained mixture was ball-milled for 2h, then washed with 3L deionized water, and vacuumed at 80°C. After drying for 12 hours, a graphite material with multi-layer graphene on the surface is obtained.

[0030] The specific preparation process of the mixed salt a is as follows: Weigh LiCl and KCl respectively according to a mass ratio of 1:1, and dissolve the weighed salt in water of 70 to 90 times the mass. Stir and heat at 6...

Embodiment 2

[0034] A negative electrode material and preparation method of graphite lithium ion battery with multilayer graphene on the surface, comprising the following steps:

[0035] (1) Take 0.5g and 4.21g KNO samples of graphite with a particle size range of 10~40μm 3 with 2.23g NH 4 Cl, ball milled for 30min, then weighed 12g of mixed salt a and continued ball milling evenly. The obtained mixture was sintered in a tube furnace at 360°C with a heating rate of 2°C / min for 6~12h in an air atmosphere, cooled to room temperature naturally, the obtained mixture was ball-milled for 2h, then washed with 3L deionized water, and vacuumed at 80°C. After drying for 12 hours, a graphite material with multi-layer graphene on the surface is obtained.

[0036] The specific preparation process of the mixed salt a is as follows: respectively weigh LiCl and KCl according to a mass ratio of 6:7, and dissolve the weighed salt in water of 70 to 90 times the mass. Stir and heat at 60~90°C for evaporati...

Embodiment 3

[0039] A negative electrode material and preparation method of graphite lithium ion battery with multilayer graphene on the surface, comprising the following steps:

[0040] (1) Take 0.5g and 4.21g KNO samples of graphite with a particle size range of 10~40μm 3 with 2.23g NH 4 Cl with 3.33g NH 4 NO 3, ball milled for 30min, then weighed 12g of mixed salt a and continued ball milling evenly. The obtained mixture was sintered in a tube furnace at 370°C with a heating rate of 2°C / min for 6-12h in an air atmosphere, cooled naturally to room temperature, ground for 2h, washed with 3L deionized water, and vacuum-treated at 80°C. After drying for 12 hours, a graphite material with multi-layer graphene on the surface is obtained.

[0041] The specific preparation process of the mixed salt a is as follows: respectively weigh LiCl and KCl according to a mass ratio of 5:7, and dissolve the weighed salt in water of 70 to 90 times the mass. Stir and heat at 60~90°C for evaporation, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com