Cmp slurry composition for polishing organic film and polishing method using same

A technology of grinding slurry and chemical machinery, which is applied to polishing compositions containing abrasives, chemical instruments and methods, and other chemical processes. It can solve problems such as difficulty in ensuring the stability of oxidants and corrosion of diamond discs, and achieve excellent grinding effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0055] Formation of an organic film: a 5000 angstrom thick silicon oxide film was deposited on a patterned wafer having an engraved pattern on its surface as a grinding stop film, and then a 2650 angstrom thick SOH film (Samsung (Samsung) was formed on the surface of the silicon oxide )SDI) to fill the engraving pattern. Here, the SOH film is formed by baking at 400°C.

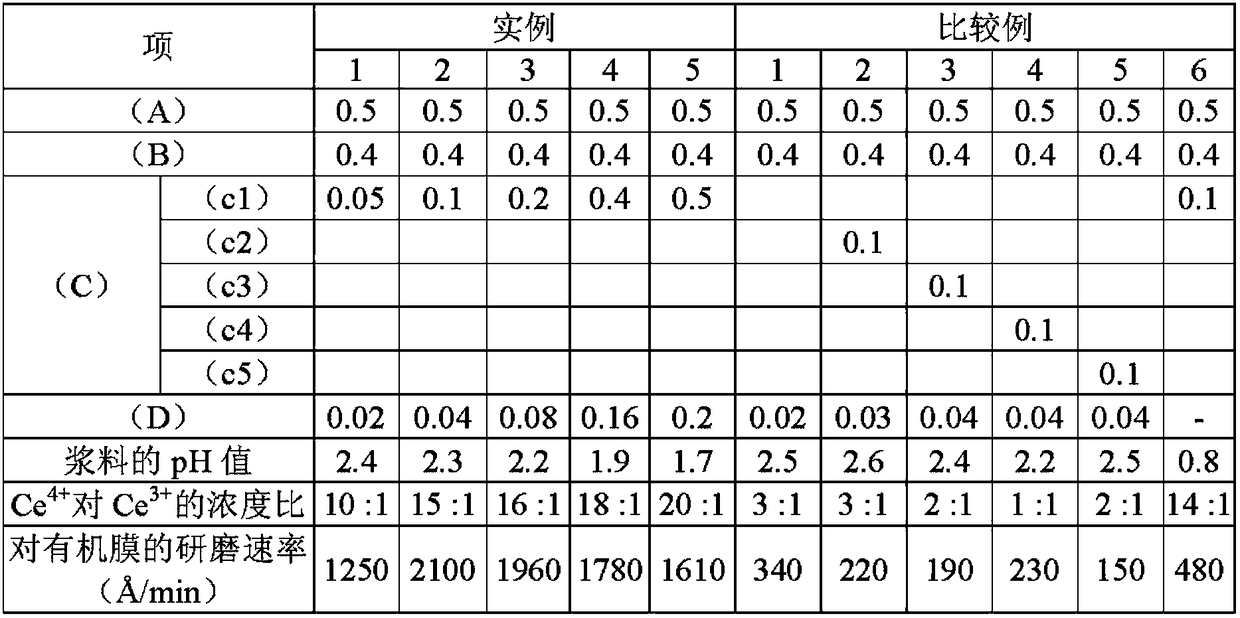

[0056] CMP slurry composition: A CMP slurry composition was prepared by mixing the following components with ultrapure water in the amounts listed in Table 1 (weight % based on the total weight of the CMP slurry composition).

[0057] The SOH film was polished using the prepared CMP slurry composition under the following polishing conditions.

[0058] Polishing conditions: An H800 CMP pad (FUJIBO Co., Ltd.) was used as a polishing pad. Under the conditions of 1.0 pounds per square inch (psi) compression pressure, 200 ml / min slurry flow rate, 90 rpm table speed and 90 rpm spindle speed Grinding was performed...

example 2 to example 5 and comparative example 1 to comparative example 6

[0060] An organic film was formed under the same conditions as in Example 1, and a CMP slurry composition was prepared using the components listed in Table 1, and then the organic film was ground in the same manner as in Example 1. Next, the grinding rate was measured. The results are shown in Table 1.

[0061] Details of the components of the CMP slurry composition

[0062] (A) Abrasive: Colloidal silica (EVONIC Co., Ltd.) with an average particle diameter of 35 nm was used.

[0063] (B) Contains Ce 4+ Ionic cerium salt: Ammonium cerium nitrate (Samchun Chemical Co., Ltd.) was used.

[0064] (C) Oxidizing agent

[0065] (c1) Hydrogen peroxide: Hydrogen peroxide (Dongwoo Fine-Chem Co., Ltd., oxidation potential: 1.77 eV) was used.

[0066] (c2) Nitric acid: Nitric acid (Samchun Chemical Co., Ltd., oxidation potential: 0.80 eV) was used.

[0067] (c3) Perchlorate: Perchlorate (Samchun Chemical Co., Ltd., oxidation potential: 0.17 eV) was used.

[0068] (c4) Hydrochlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com