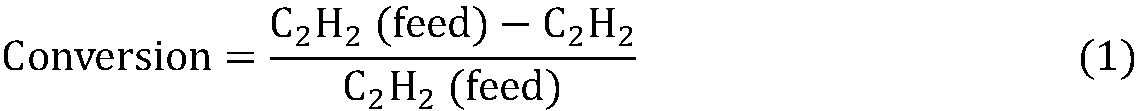

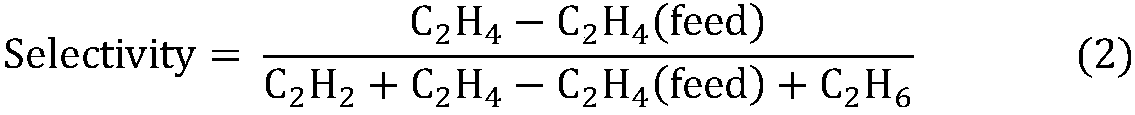

Method for selective hydrogenation of acetylene to ethylene

A selective, acetylene hydrogenation technology, applied in chemical instruments and methods, hydrogenation to hydrocarbons, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of low selectivity of Pd catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Will H 2 PdCl 4 0.01mol·L -1 And Ni(C 2 H 3 O 2 ) 2 0.01mol·L -1 Dissolve in tetrahydrofuran, add 1 times equivalent of PPh to the system 3 Ligand. After stirring for 0.5h, add a certain amount of sodium borohydride to make the concentration of sodium borohydride 0.1mol·L -1 . After stirring for 2h, the solvent was evaporated, the product was washed with n-hexane, and finally extracted with dichloromethane. Dissolve the metal cluster protected by the ligand in methanol, add a certain amount of tetramethylorthosilicate to make the final mass ratio of total metal to silica 0.01%, and add concentrated ammonia (mass Concentration 28%), until all silicone ester is hydrolyzed. After washing and drying, it is calcined under oxygen at 200℃ for 1h. Take H 2 1%, ethylene 50%, acetylene 0.1%, the rest is helium, normal pressure, reaction temperature is 50℃, space velocity is 10000h -1 , Carry out selective hydrogenation reaction. The conversion rate is 90%, and the ethylene sel...

Embodiment 2

[0015] Put Ni(C 2 H 3 O 2 ) 2 0.01mol·L -1 Dissolve in tetrahydrofuran, add 1 equivalent of PPh to the system 3 Ligand. After stirring for 0.5h, add a certain amount of sodium borohydride to make the concentration of sodium borohydride 0.1mol·L -1 . After stirring for 2h, the solvent was evaporated, the product was washed with n-hexane, and finally extracted with dichloromethane. Dissolve the metal cluster protected by the ligand in methanol, add a certain amount of tetramethylorthosilicate to make the final mass ratio of total metal to silica 0.01%, and add concentrated ammonia (mass Concentration 28%), until all silicone ester is hydrolyzed. After washing and drying, it is calcined in oxygen at 200℃ for 1h. Take H 2 1%, ethylene 50%, acetylene 0.1%, the rest is helium, normal pressure, reaction temperature is 50℃, space velocity is 10000h -1 , Carry out selective hydrogenation reaction. The conversion rate is 85%, and the ethylene selectivity is 95%.

Embodiment 3

[0017] Will H 2 PdCl 4 0.01mol·L -1 With Cu(C 2 H 3 O 2 ) 2 0.01mol·L -1 Dissolve in tetrahydrofuran, add 1 equivalent of PPh to the system 3 Ligand. After stirring for 5h, add a certain amount of sodium borohydride to make the concentration of sodium borohydride 0.1mol·L -1 . After stirring for 2h, the solvent was evaporated, the product was washed with n-hexane, and finally extracted with dichloromethane. The metal cluster protected by the ligand is dissolved in methanol, and a certain amount of tetramethyl orthosilicate is added to make the final mass ratio of total metal to silicon dioxide 0.01%. Add ammonia (mass concentration) dropwise to the system. 28%), until the silicone ester is completely hydrolyzed. After washing and drying, it is calcined at 200℃ for 1h under a condition of oxygen. Take H 2 1%, ethylene 50%, acetylene 0.1%, the rest is helium, normal pressure, reaction temperature is 50℃, space velocity is 10000h -1 , Carry out selective hydrogenation reaction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com