Technology for shortening extracting time of chondroitin sulfate

A chondroitin sulfate and extraction time technology is applied in the technical field of shortening chondroitin sulfate extraction time, and can solve the problems of low protein removal rate, low yield, poor enzymatic hydrolysis effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

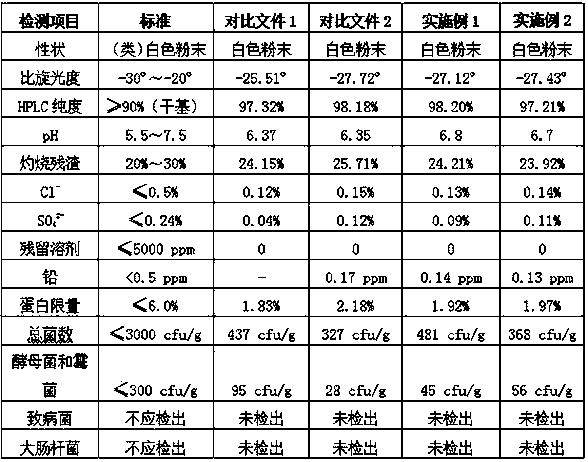

Examples

Embodiment 1

[0029] A process for shortening the extraction time of chondroitin sulfate, comprising the following steps:

[0030] (1) Cartilage pretreatment: Weigh 1000kg of bovine nasal bone, and use ultrasonic wave in 0.02mol / L NaHCO 3 Wash in the cleaning solution, then put the cleaned cartilage into the extraction tank, add 8 times distilled water, heat it with coil tube and direct steam to 105°C, keep it warm for 3 hours, then take out the upper layer of bone oil, control the stirring speed to 60rpm, use The coil cools the cooking liquor to 50°C;

[0031] (2) Double enzymatic hydrolysis: adjust the pH value of the cooking liquid to 9.0, add alkaline protease 2709 with 0.8% cartilage mass, stir at 40 rpm, and enzymatically hydrolyze for 2 hours; readjust the pH value to 8.7, and add 6% cartilage mass protease Activation of porcine pancreas (crushed porcine pancreas, activated at 25-35°C for 50 h), stirring at 40 rpm, enzymatic hydrolysis for 2 h;

[0032] (3) Deproteinization: raise ...

Embodiment 2

[0040] A process for shortening the extraction time of chondroitin sulfate, comprising the following steps:

[0041] (1) Cartilage pretreatment: Weigh 1000kg of bovine nasal bone, and use ultrasonic wave in 0.05mol / L NaHCO 3 Wash in the cleaning solution, then put the cleaned cartilage into the extraction tank, add 7 times of distilled water, heat it with coil tube and direct steam, heat it to 105°C, keep it warm for 3 hours, then take out the upper layer of bone oil, and control the stirring speed to 60 rpm , using coils to cool the cooking liquid to 50°C;

[0042] (2) Double enzymatic hydrolysis: adjust the pH value of the cooking liquid to 9.0, add alkaline protease 2709 with 0.9% cartilage mass, stir at 40 rpm, and enzymolyze for 2 h; readjust the pH value to 8.7, add 5% cartilage mass Activated porcine pancreas (crushed porcine pancreas, activated at 25-35°C for 40 h), stirred at 40 rpm, and enzymatically hydrolyzed for 2 h;

[0043] (3) Deproteinization: raise the temper...

Embodiment 3

[0053] Except that the bovine nasal bone was replaced by the bovine throat pipe, the others were the same as in Example 1, the yield of chondroitin sulfate was 18.8%, the purity was 96.8%, and the extraction time was 7 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com