Hydrolysis resistant waterborne polyurethane dispersoid and preparation methd thereof

A technology of water-based polyurethane and dispersion, applied in the field of water-based polyurethane, can solve the problems of poor water resistance, achieve the effects of improving lipophilicity, good hydrolysis resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

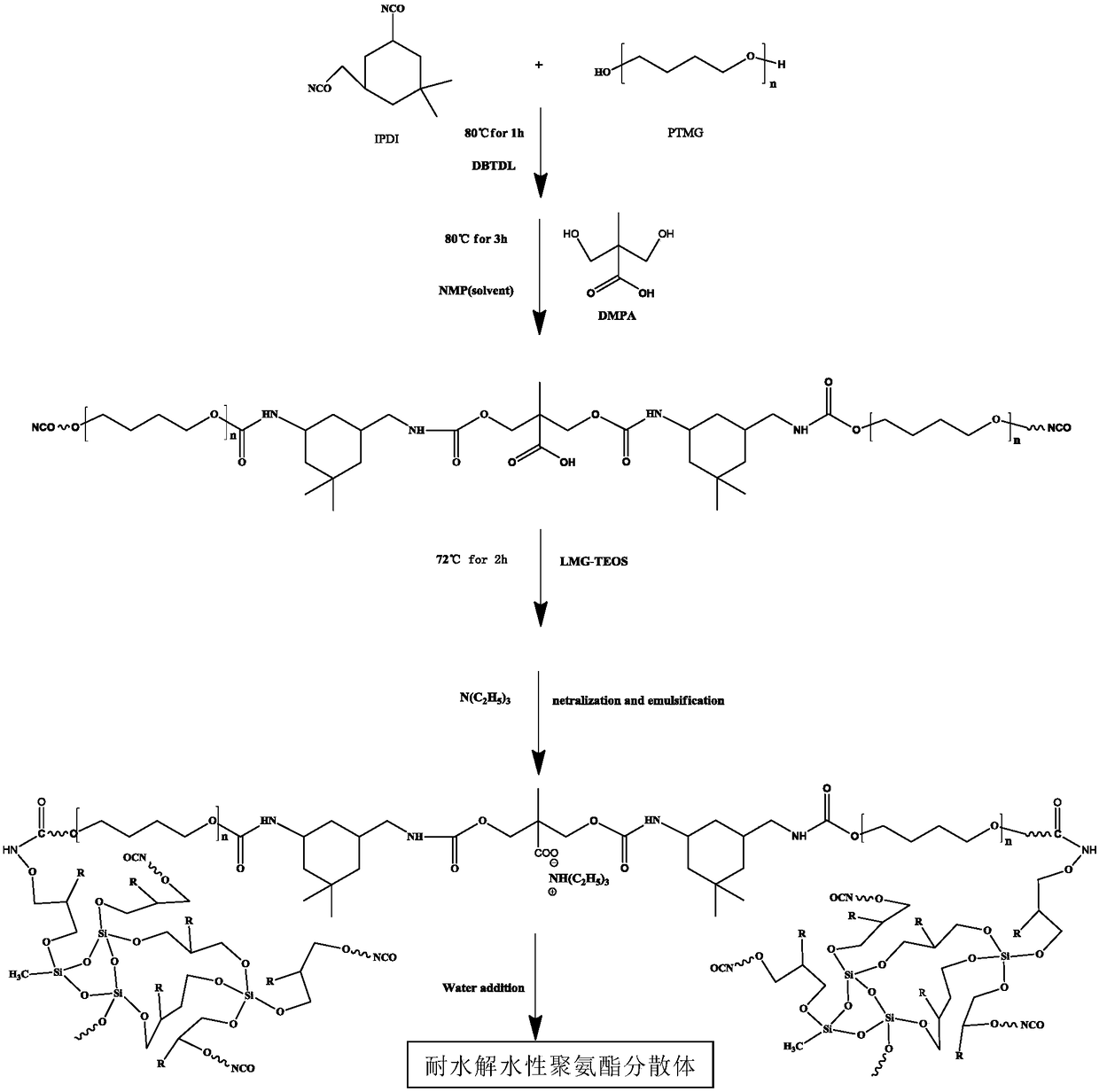

[0027] A kind of hydrolysis-resistant aqueous polyurethane dispersion, it is prepared by following method:

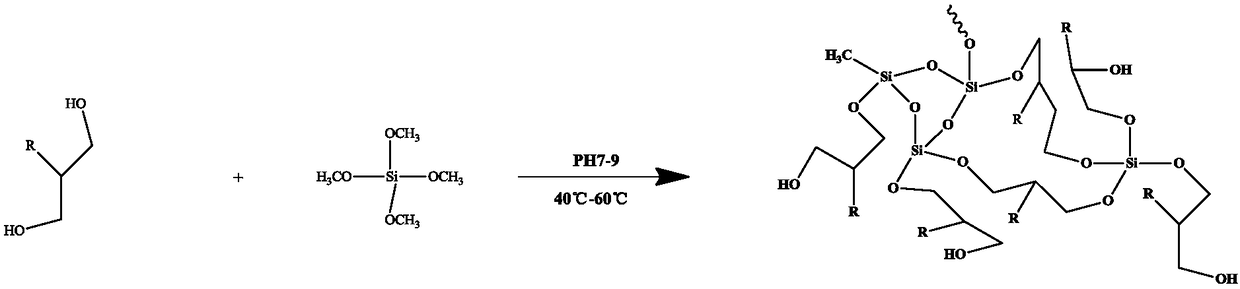

[0028] S1. In a 100mL three-neck flask, blow nitrogen, take 0.5227g monolinolenic acid glyceride (LMG) and dissolve it in 15mL methyl ethyl ketone solvent, and adjust the solution to weak alkaline (pH=8) with ammonia water, stir at 60°C for one hour, Then, 0.0528g tetraethyl orthosilicate (TEOS) was dissolved in 5mL methyl ethyl ketone solvent and added dropwise to a three-necked flask, and reacted for 3h to obtain a compound containing glycerol monolinolenate and tetraethyl orthosilicate.

[0029] (LMG-TEOS nanocomposite) mixed solution, the specific reaction equation of S1 is as figure 1 shown;

[0030] S2. In a 250mL four-neck bottle equipped with a reflux device and a mechanical stirrer and protected by nitrogen, add 3g of polytetrahydrofuran (PTMG2000), 25mL of acetone and 0.3g of dibutyltin dilaurate (DBTDL) after drying , add and then heat up to 80°C, after the...

Embodiment 2

[0032] A kind of hydrolysis-resistant aqueous polyurethane dispersion, it is prepared by following method:

[0033] S1. In a 100mL three-neck flask, blow nitrogen, take 0.60g of monolinolenic acid glyceride (LMG) and dissolve it in 15mL of methyl ethyl ketone solvent, and adjust the solution to weak alkaline (pH=9) with ammonia water, and stir at 40°C for one hour. Then 0.06g tetraethyl orthosilicate (TEOS) was dissolved in 5mL methyl ethyl ketone solvent and added dropwise to a three-necked flask, and reacted for 4h to obtain a complex containing glycerol monolinolenate and tetraethyl orthosilicate.

[0034] (LMG-TEOS nanocomposite material) mixed solution;

[0035] S2. Add 3g (0.0015mol) of dried polytetrahydrofuran (PTMG2000), 30mL of acetone and 0.4g of dilauric acid di Add butyltin (DBTDL) and heat up to 75°C. After the system becomes a uniform and stable solution, add 0.0082mol of isophorone diisocyanate (IPDI), react at 75°C for 1 hour, add 0.0018mol of 2,2-dimethylol ...

Embodiment 3

[0037] A kind of hydrolysis-resistant aqueous polyurethane dispersion, it is prepared by following method:

[0038]S1. In a 100mL three-neck flask, blow nitrogen, take 0.50g of monolinolenic acid glyceride (LMG) and dissolve it in 15mL of methyl ethyl ketone solvent, and adjust the solution to weak alkaline (pH=7) with ammonia water, and stir at 40°C for one hour. Then 0.05g tetraethyl orthosilicate (TEOS) was dissolved in 5mL of methyl ethyl ketone solvent and added dropwise to a three-necked flask, and reacted for 3 hours to obtain a complex containing glycerol monolinolenate and tetraethyl orthosilicate (LMG-TEOS nanocomposite material) mixture;

[0039] S2. Add 3g (0.0015mol) of dried polytetrahydrofuran (PTMG2000), 28mL of acetone and 0.6g of dilauric acid di Add butyltin (DBTDL) and heat up to 85°C. After the system becomes a uniform and stable solution, add 0.0098mol of isophorone diisocyanate (IPDI), react at 85°C for 1 hour, add 0.0023mol of 2,2-dimethylol Propionic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com