Livestock manure biodegradation mixed culture, carrier and method

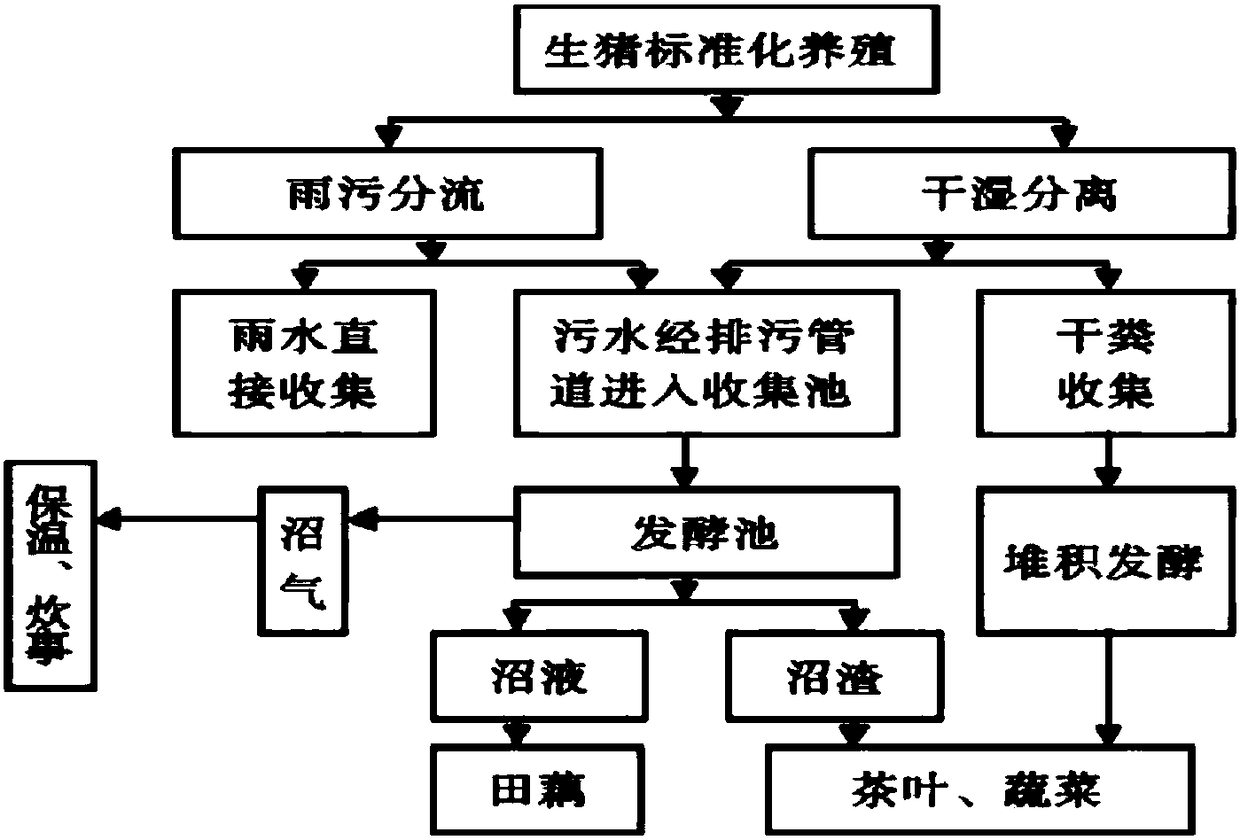

A technology of mixing bacteria and feces, which is applied in the field of mixed bacteria for the degradation of biological feces of livestock and poultry, can solve the problems of high cost, many equipment and long time period, saving construction costs, saving land resources, and maintaining a constant temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] Step 1, preparation of mixed strains

[0051] According to a certain ratio of the number of bacteria, take an appropriate amount of Bacillus subtilis, Bacillus pumilus, Bacillus cereus, Bacillus licheniformis, Acinetobacter ruckeri and Alcaligenes faecalis to prepare the required mixed strains, the specific The preparation process is:

[0052] (1) Slope culture of strains:

[0053] Bacillus subtilis, Bacillus pumilus, Bacillus cereus, Bacillus licheniformis, Acinetobacter ruckeri and Alcaligenes faecalis in cryopreservation tubes were respectively activated on a slant, and then placed in suitable petri dishes for Purify to obtain Bacillus subtilis, Bacillus pumilus, Bacillus cereus, Bacillus licheniformis, Acinetobacter ruckeri and Alcaligenes faecalis for later use.

[0054] In step (1), the specific steps for the activation of Bacillus subtilis in the slant are: use an inoculation loop to inoculate Bacillus subtilis on the sterilized slant medium I, and then cultiva...

Embodiment 1

[0080] A mixed bacterial species for the degradation of livestock and poultry biological manure, which is composed of the following microorganisms: Bacillus subtilis, Bacillus pumilus, Bacillus cereus, Bacillus licheniformis, Acinetobacter ruckerii, Alcaligenes faecalis and microbial metabolic active products , the mixed strain is a yellow liquid, and the range ratio of the bacterial count of each strain is: the colony count of Bacillus subtilis in the mixed strain is 6-3 billion cfu / g, and the colony count of Bacillus pumilus in the mixed strain is 7-3.5 billion cfu / g, the number of colonies of Bacillus cereus in the mixed strains is 6-3.5 billion cfu / g, the number of colonies of Bacillus licheniformis in the mixed strains is 7-3 billion cfu / g, Lu The number of colonies of Acinetobacter faecalis in the mixed strains is 300-1500 million cfu / g, and the number of colonies of Alcaligenes faecalis in the mixed strains is 400-1200 million cfu / g.

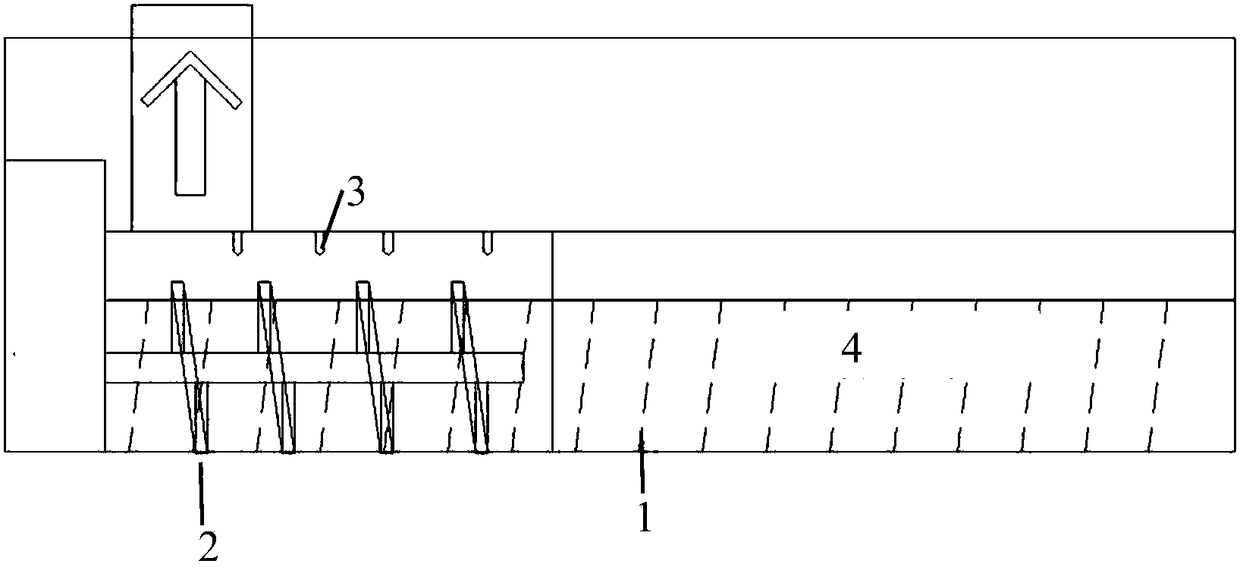

[0081] The carrier used to carry t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com