Semiconductor device and manufacturing method, and electronic device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve the problems of polysilicon damage, active area etching damage, affecting the overall performance and yield of the device, etc. The effect of improving performance and yield, improving margins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

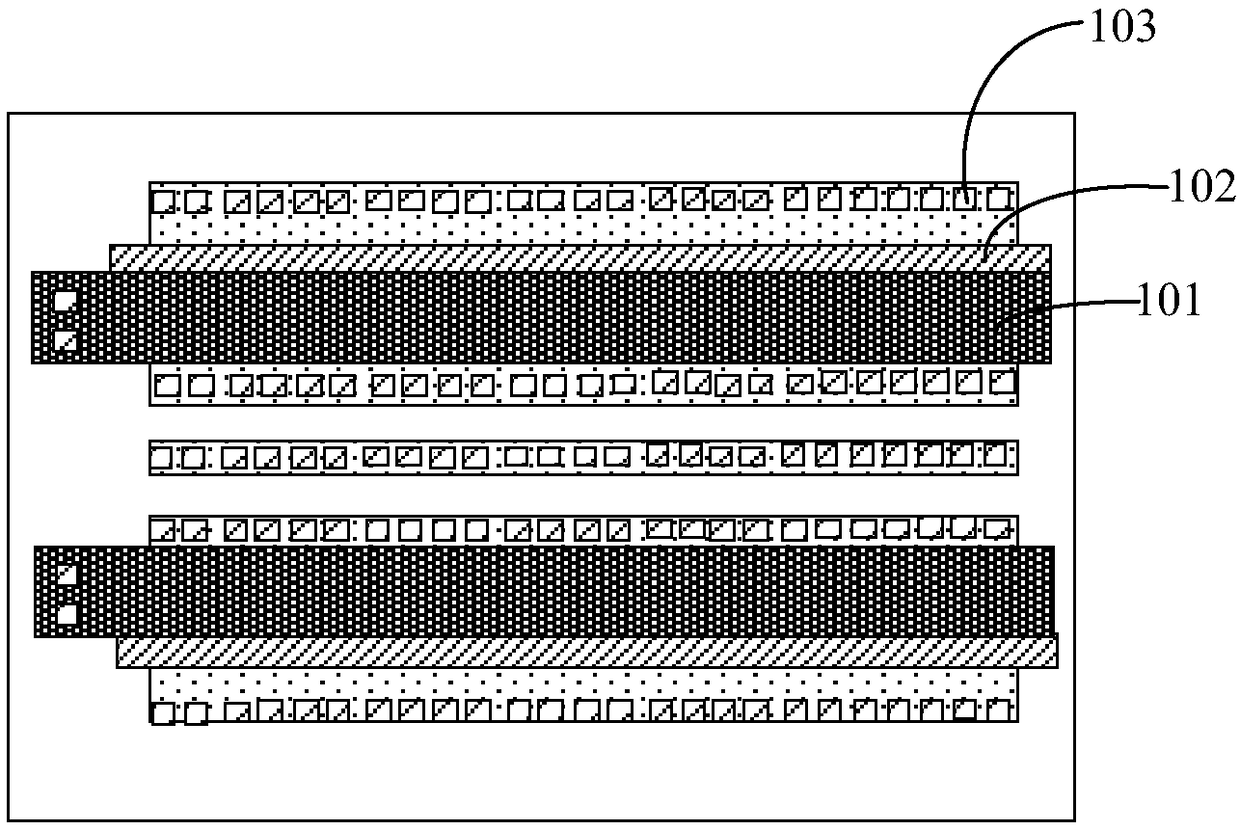

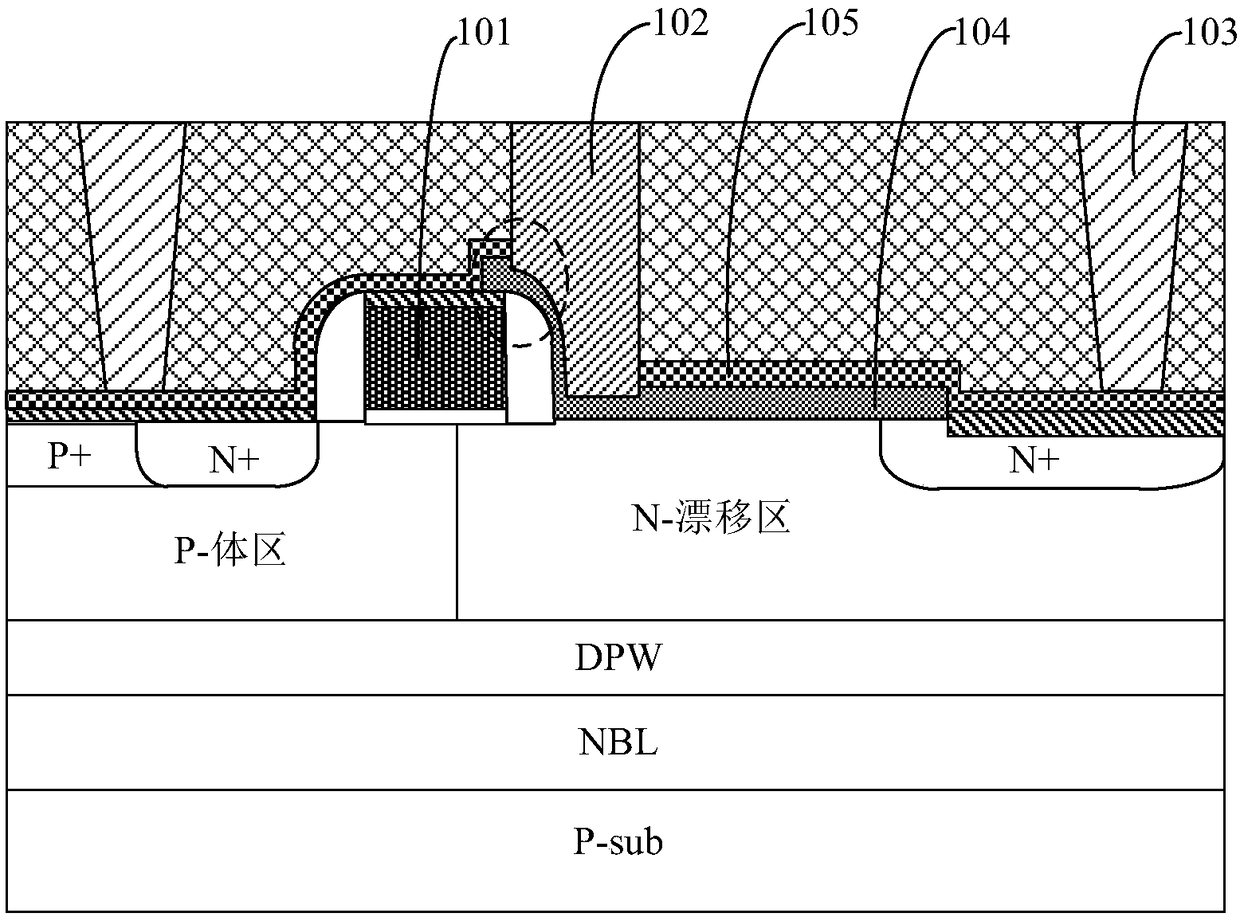

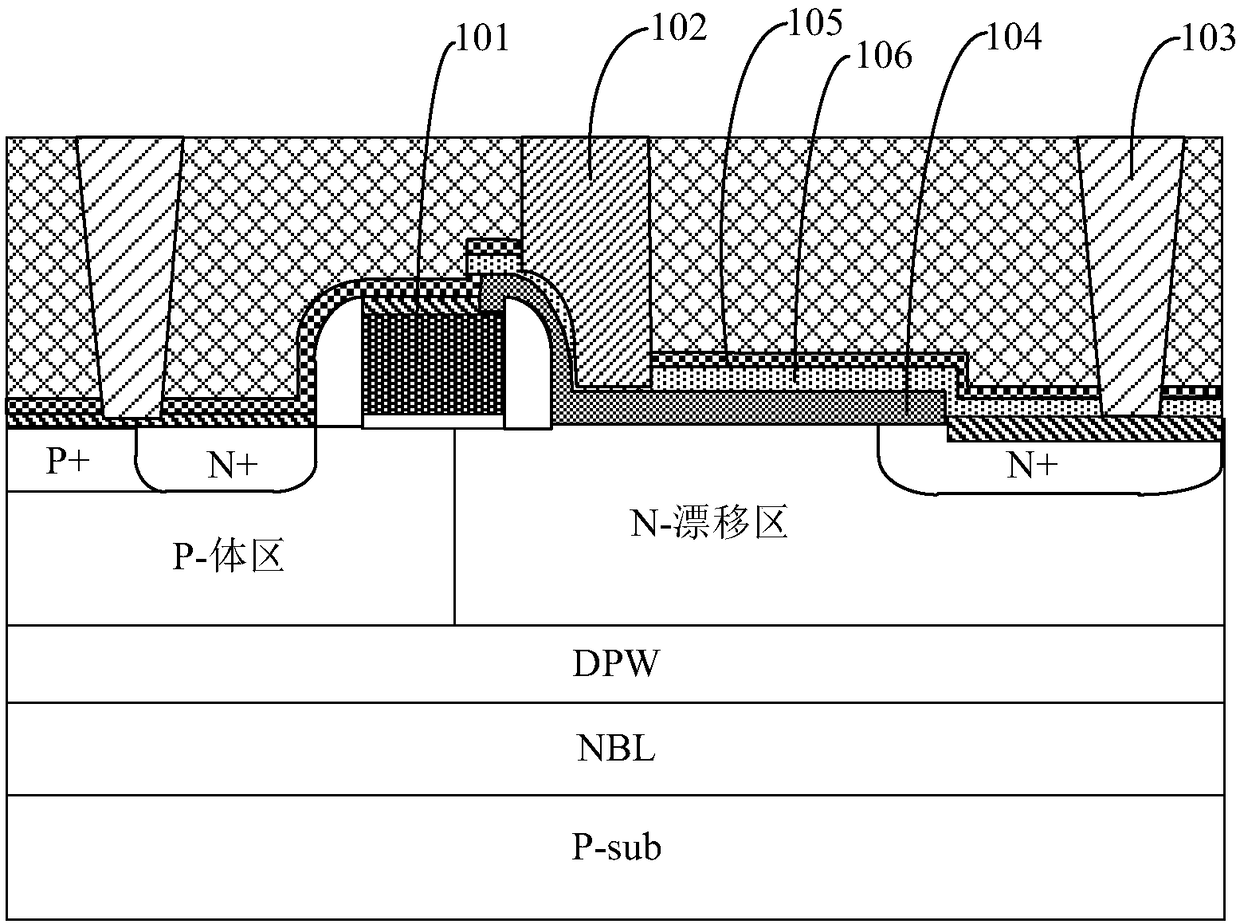

[0070] In order to solve the above technical problems, the present invention provides a semiconductor device, such as image 3 shown, which includes:

[0071] a semiconductor substrate of the first conductivity type;

[0072] a gate structure formed on the semiconductor substrate;

[0073] A source and a drain are formed in the semiconductor substrate on both sides of the gate structure, there is a space between the drain and the gate structure, and a connection line between the source and the drain is defined The extending direction is the first direction;

[0074] a trench contact formed on the semiconductor substrate between the gate structure and the drain, wherein the trench contact includes a body portion and several Comb teeth, the main body part is provided with the comb teeth along at least one side in the first direction.

[0075] The trench contact of the semiconductor device of the present invention includes a main body and several comb teeth connected to the m...

Embodiment 2

[0125]The present invention also provides a method for manufacturing the semiconductor device in the aforementioned implementation one, such as image 3 As shown, it mainly includes the following steps:

[0126] Step S1, providing a semiconductor substrate of the first conductivity type;

[0127] Step S2, forming a gate structure on the semiconductor substrate;

[0128] Step S3, forming a source and a drain in the semiconductor substrate on both sides of the gate structure, wherein there is a gap between the drain and the gate structure, defining a gap between the source and the drain The extension direction of the connecting line is the first direction;

[0129] Step S4, forming a trench contact on the semiconductor substrate between the gate structure and the drain, wherein the trench contact includes a body part and several comb teeth connected to the body part, The main body portion is provided with the comb teeth along at least one side in the first direction.

[0130...

Embodiment 3

[0192] The present invention also provides an electronic device, including the semiconductor device described in Embodiment 1, or the semiconductor device prepared by using the manufacturing method described in Embodiment 2.

[0193] The electronic device of this embodiment can be any electronic device such as a mobile phone, a tablet computer, a notebook computer, a netbook, a game console, a TV set, a VCD, a DVD, a navigator, a digital photo frame, a camera, a video camera, a recording pen, MP3, MP4, PSP, etc. Product or equipment, but also any intermediate product including electrical circuits. The electronic device according to the embodiment of the present invention has better performance due to the use of the above-mentioned semiconductor device.

[0194] in, Figure 4 An example of a mobile phone handset is shown. The mobile phone handset 400 is provided with a display portion 402 included in a housing 401, operation buttons 403, an external connection port 404, a spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com