Environmentally friendly high impermeability and anti-cracking agent

An anti-cracking agent and high-resistance technology, which is applied in the field of building materials, can solve the problems that the anti-cracking performance and impermeability performance need to be improved, and cannot adapt to the development of concrete strength, so as to improve the compactness of concrete, compensate for concrete shrinkage, and improve The effect of anti-permeability and anti-crack performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048]Raw materials (parts by weight) of environmental protection high impermeability and anti-cracking agent: 20 parts of expanded clinker, 30 parts of anhydrite, 25 parts of calcined coal gangue, 15 parts of zeolite powder, 3 parts of magnesium oxide, 3 parts of water-retaining agent, 2 parts of water-reducing agent 1 part, 1 part of polyethylene glycol, 0.5 part of sodium gluconate, and 0.5 part of sodium stearate.

[0049] The water retaining agent is methyl cellulose.

[0050] The water reducer is a polycarboxylate water reducer.

[0051] The present invention also provides a preparation method of an environment-friendly high impermeability and anti-cracking agent, comprising the following steps:

[0052] (1) Dry the expanded clinker, anhydrite, calcined coal gangue, zeolite powder, and magnesium oxide at 105°C for 3 hours;

[0053] (2) Add the dried raw materials in the step (1) to a mill and mix and grind to 300 mesh to obtain a mixed powder;

[0054] (3) Add water-r...

Embodiment 2

[0056] Raw materials (parts by weight) of environmental protection high impermeability and anti-cracking agent: 20 parts of expanded clinker, 30 parts of anhydrite, 25 parts of calcined coal gangue, 15 parts of modified zeolite powder, 3 parts of magnesium oxide, 3 parts of water-retaining agent, water-reducing agent 2 parts of agent, 1 part of polyethylene glycol, 0.5 part of sodium gluconate, and 0.5 part of sodium stearate.

[0057] The water retaining agent is methyl cellulose.

[0058] The water reducer is a polycarboxylate water reducer.

[0059] The preparation method of described modified zeolite powder comprises the following steps:

[0060] (1) Place the zeolite powder in a muffle furnace, roast at 500°C for 3 hours, cool naturally to room temperature and pass through a 300-mesh sieve to obtain activated zeolite powder;

[0061] (2) Mix activated zeolite powder and 0.5mol / L titanium sulfate aqueous solution at a solid-to-liquid ratio of 1g: 15mL, stir at 25°C at 20...

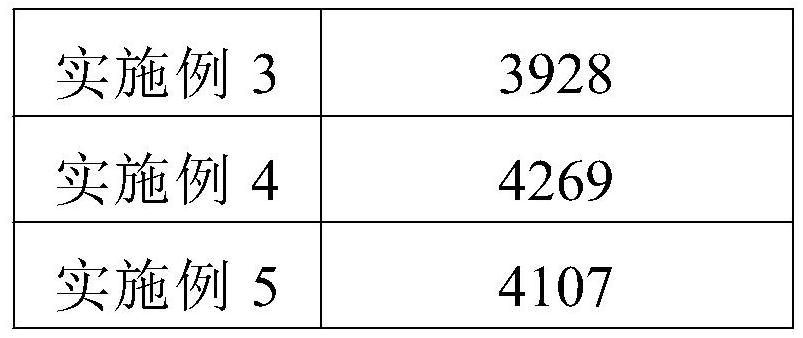

Embodiment 3

[0078] Raw materials (parts by weight) of environmental protection high impermeability and anti-cracking agent: 20 parts of expanded clinker, 30 parts of anhydrite, 25 parts of calcined coal gangue, 15 parts of modified zeolite powder, 3 parts of magnesium oxide, 3 parts of water-retaining agent, water-reducing agent 2 parts of agent, 1 part of polyethylene glycol, 0.5 part of sodium gluconate, and 0.5 part of sodium stearate.

[0079] The water retaining agent is hydroxypropyl methylcellulose.

[0080] The water reducer is a polycarboxylate water reducer.

[0081] The preparation method of described modified zeolite powder comprises the following steps:

[0082] (1) Place the zeolite powder in a muffle furnace, roast at 500°C for 3 hours, cool naturally to room temperature and pass through a 300-mesh sieve to obtain activated zeolite powder;

[0083] (2) Mix activated zeolite powder and 0.5mol / L titanium sulfate aqueous solution at a solid-to-liquid ratio of 1g: 15mL, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com