Electromagnetic shielding silicon rubber/graphene/silver nanowire nano composite material and preparation method thereof

A nanocomposite material and silver nanowire technology, which is applied in the fields of magnetic/electric field shielding and electrical components, can solve the problems of high conductivity, uniform and continuous conductive network, low conductivity of the conductive network, etc., and achieve high filler utilization and excellent stability performance and reliability, and the effect of avoiding the use of dispersing aids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

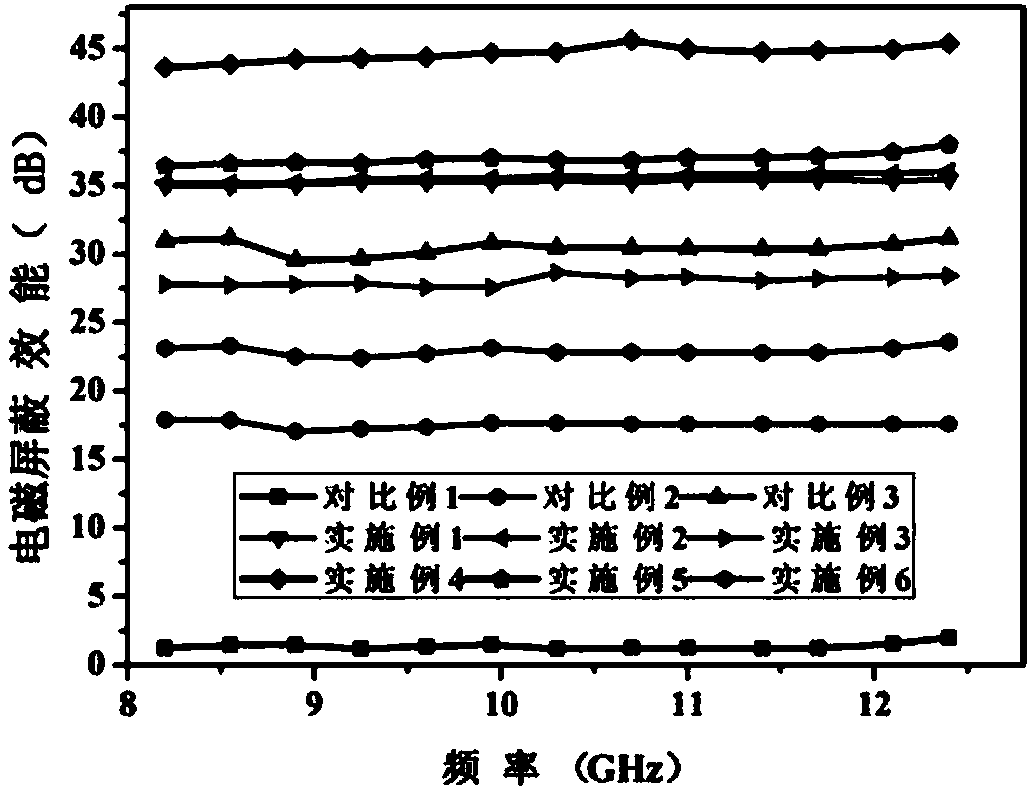

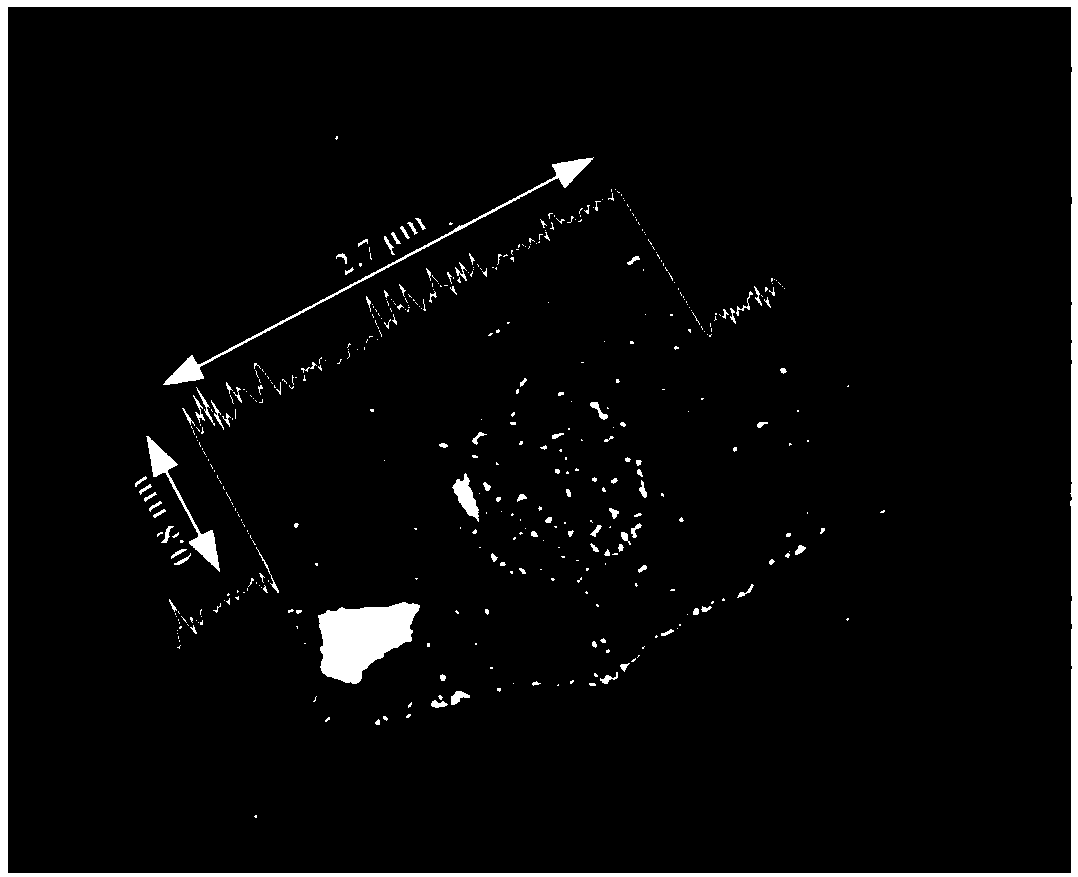

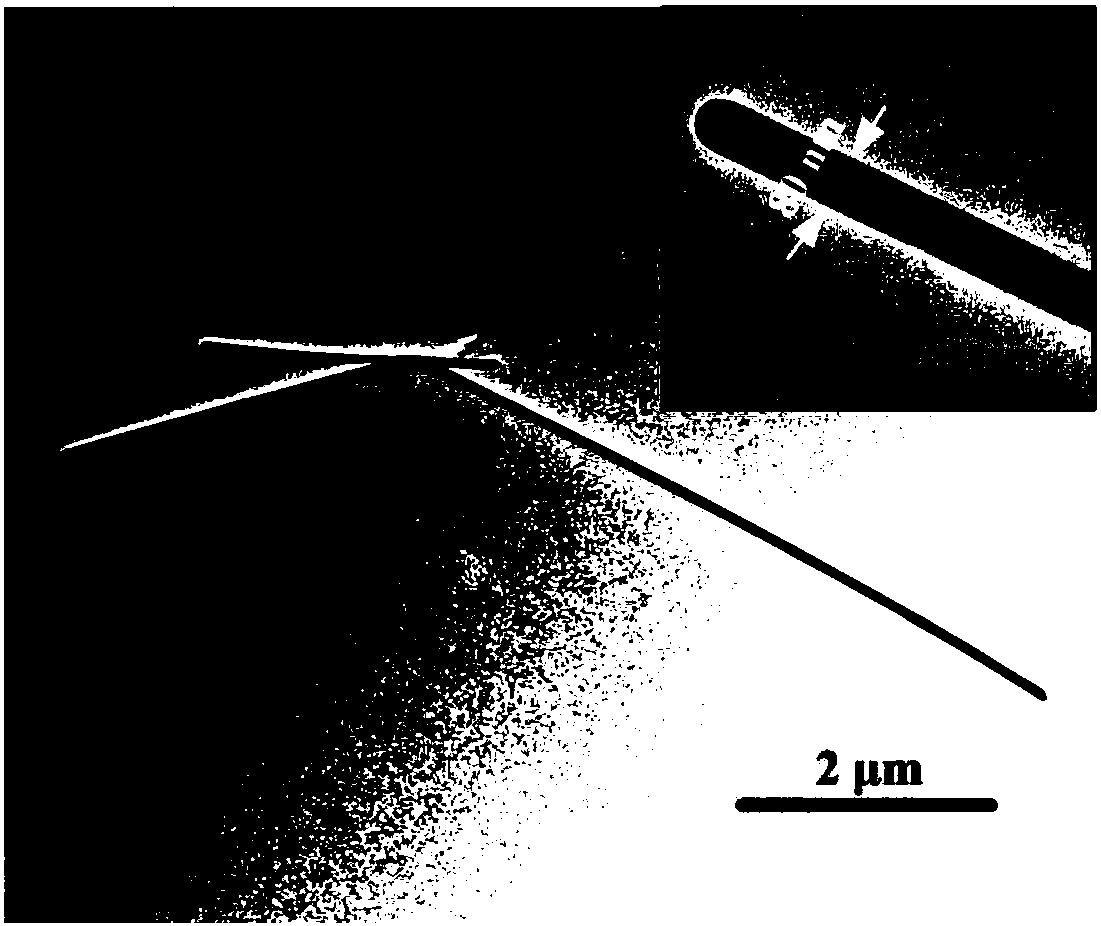

[0045] A silicon rubber / graphene / silver nanowire nanocomposite material for electromagnetic shielding, the three-dimensional conductive network skeleton of the composite material is a three-dimensional continuous porous material interwoven with graphene and silver nanowires, and its composition is an addition liquid 100 parts by mass of silicone rubber (Momentive RTV615, matrix resin: curing agent = 10:1), 0.5 parts by mass of graphene, 0.1 part by mass of silver nanowires (Beijing Deke Island Gold, diameter ~ 80nm, length 1 ~ 10 μm). The composite material is prepared by the following steps:

[0046] 1) Graphite oxide was prepared by the Hummers method, and then water was used as a medium to prepare a graphene oxide aqueous dispersion by ultrasonically exfoliating graphite oxide. The concentration of graphite oxide is 10mg / ml, and the ultrasonic treatment condition is 200W / 250kHz / 30min.

[0047] 2) adding the silver nanowires to the graphene oxide aqueous dispersion, and ult...

Embodiment 2

[0054] A silicon rubber / graphene / silver nanowire nanocomposite material for electromagnetic shielding, the three-dimensional conductive network skeleton of the composite material is a three-dimensional continuous porous material interwoven with graphene and silver nanowires, and its composition is an addition liquid 100 parts by mass of silicone rubber (Momentive RTV615, matrix resin: curing agent = 10:1), 0.5 parts by mass of graphene, 0.1 part by mass of silver nanowires (Beijing Deke Island Gold, diameter ~ 80nm, length 1 ~ 10 μm). This composite material adopts the steps similar to embodiment 1 to prepare, and difference is:

[0055] In step 1), high-speed stirring is used instead of ultrasonically exfoliating graphite oxide to prepare a graphene oxide aqueous dispersion. The high-speed stirring condition is 5000rpm / 60min.

[0056]In step 2), high-speed stirring is used instead of ultrasound to prepare the graphene oxide / silver nanowire aqueous dispersion. The high-speed...

Embodiment 3

[0059] A silicon rubber / graphene / silver nanowire nanocomposite material for electromagnetic shielding. The three-dimensional conductive network skeleton of the composite material is a three-dimensional continuous porous material interwoven with graphene and silver nanowires. Its composition is a condensation type room temperature 100 parts by mass of vulcanized silicone rubber (Chengdu Senfa, one-component), 0.05 parts by mass of graphene, and 0.05 parts by mass of silver nanowires (Pioneer Nano XFJ81, diameter ~ 30 nm, length 100 ~ 200 μm). This composite material adopts the steps similar to embodiment 1 to prepare, and difference is:

[0060] In step 1), high-speed stirring is used to exfoliate graphite oxide to prepare a graphene oxide aqueous dispersion. The concentration of graphite oxide is 1mg / ml, and the high-speed stirring condition is 3000rpm / 120min.

[0061] In step 2), high-speed stirring is used to prepare the graphene oxide / silver nanowire aqueous dispersion. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Electromagnetic shielding effectiveness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com