Water-blocking repairing adhesive tape used for photovoltaic module backboard and preparation method of adhesive tape

A photovoltaic module, repair tape technology, applied in the direction of adhesives, film/sheet adhesives, coatings, etc., can solve problems such as electric leakage and fire, glass cracks, delamination, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

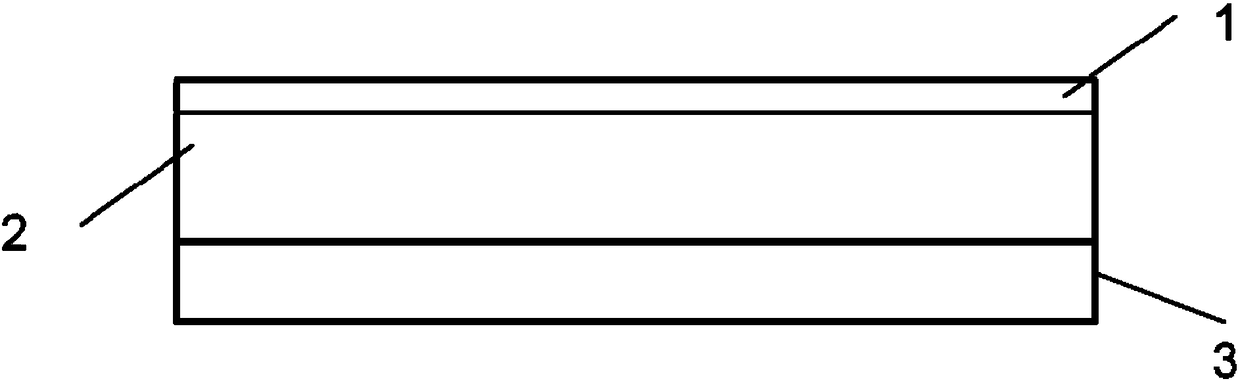

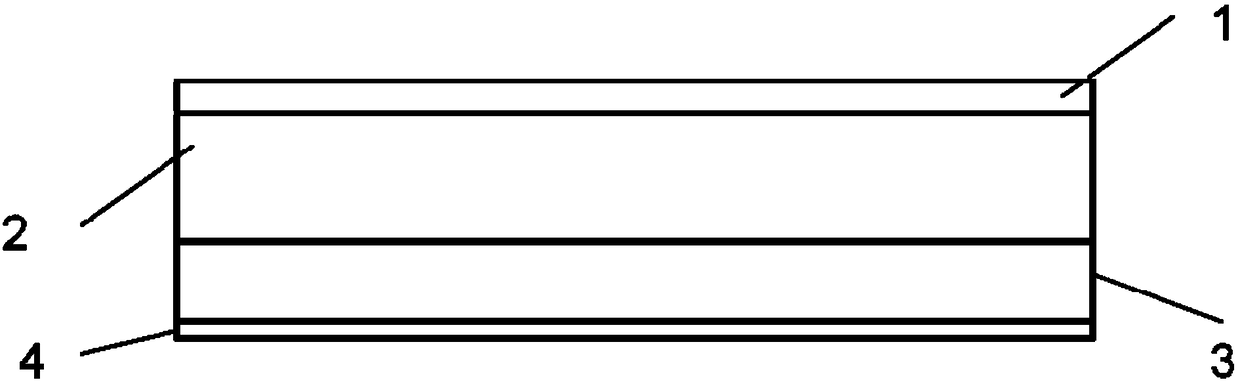

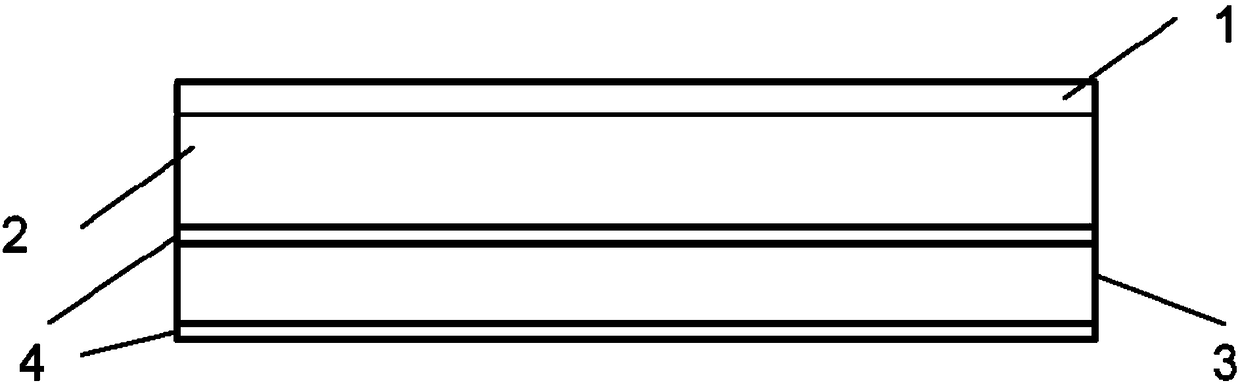

Image

Examples

Embodiment 1

[0028] First prepare a 50um white polyethylene naphthalate film as the air surface base film layer and a 20um polypropylene film as the release film layer. Then prepare polybutene, N-β-(aminoethyl)-γaminopropyltrimethoxysilane modified metallocene catalyst according to the ratio of mass parts 100:5:5:10:20:5:0.1 Vinyl copolymer, terpene resin, carbon black, talc, anhydrous calcium chloride, and pentaerythritol tetrakis(3,5-di-tert-butyl-4-hydroxy)phenylpropionate, through the above-mentioned intermediate water-blocking adhesive layer The kneading preparation method produces a uniform adhesive. Then add the prepared uniform adhesive to the screw extruder, extrude at the processing temperature of the above-mentioned screw extruder, control the thickness of the extruded layer at 100um, and then bond the two sides of the base film layer and the release film, after Rolling, cooling and setting, trimming and winding.

Embodiment 2

[0030] First, prepare a 160um white polybutylene terephthalate film as the air surface base film layer and a 50 micron Guevara release paper as the release film layer. Then prepare polyisobutylene, γ-aminopropyltrimethoxysilane modified isobutylene-p-methylstyrene copolymer, rosin resin, white Carbon black, montmorillonite, anhydrous calcium sulfate, and bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, prepared by the kneading preparation method of the intermediate water-blocking adhesive layer to obtain a uniform adhesive material. Then add the prepared uniform adhesive to the screw extruder, extrude at the above-mentioned screw extruder processing temperature, control the thickness of the extruded layer at 150um, and then bond the two sides of the base film layer and the release film, after Rolling, cooling and setting, trimming and winding.

Embodiment 3

[0032] First prepare a 250um white polyethylene terephthalate film as the base film layer of the air surface and a 36 micron Guevara release paper as the release film layer. Then prepare polyisobutylene, γ-aminopropyltrimethoxysilane modified isobutylene-p-methylstyrene copolymer, rosin resin, white Carbon black, montmorillonite, anhydrous calcium sulfate, and bis(2,4-di-tert-butylphenyl)pentaerythritol diphosphite, prepared by the kneading preparation method of the intermediate water-blocking adhesive layer to obtain a uniform adhesive material. Then add the prepared uniform adhesive to the screw extruder, extrude at the processing temperature of the above-mentioned screw extruder, control the thickness of the extruded layer at 100um, and then bond the two sides of the base film layer and the release film, after Rolling, cooling and setting, trimming and winding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com