Negative electrode material of high-voltage thermal battery, high-voltage thermal battery and preparation method thereof

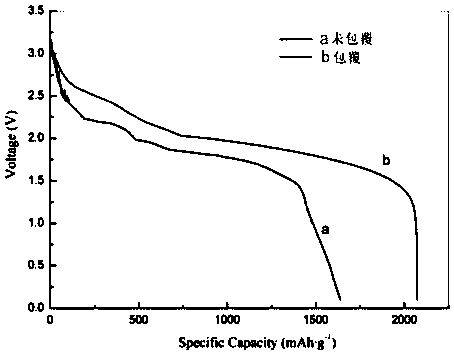

A negative electrode material, thermal battery technology, applied in the electrode of primary battery, battery electrode, circuit, etc., can solve the problem of low working voltage of thermal battery, and achieve the effect of increasing working voltage, discharge voltage, and discharge specific capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A negative electrode material for a high-voltage thermal battery, which is composed of a lithium-silicon alloy and lithium fast ion conductor lithium borate-lithium sulfate coated on the surface of the lithium-silicon alloy; the lithium fast ion conductor lithium borate-lithium sulfate is added in an amount of 20% by weight; lithium fast ion conductor lithium borate-lithium sulfate is prepared by mixing lithium borate crystals and anhydrous lithium sulfate crystals, the mass percentage of lithium borate crystals is 40%; the mass percentage of anhydrous lithium sulfate crystals is 60% %.

[0036] The preparation method of the above-mentioned lithium fast ion conductor lithium borate-lithium sulfate is:

[0037] 1) Analyzing the pure grade LiOH·H from the raw material 2 O and H 3 BO 3 respectively in Al 2 o 3 The crucible was treated at a constant temperature of 500 °C for 1 h, and then the two were sintered at a high temperature of 600 °C for 2 h in an air atmospher...

Embodiment 2

[0041]A high-voltage thermal battery is composed of positive electrode material, negative electrode material and electrolyte diaphragm material, by weight, the content of positive electrode material is 44%; the content of negative electrode material is 21%; the content of electrolyte diaphragm material is 35%; wherein, the positive electrode The material is manganese dioxide material, the negative electrode material is a high-pressure thermal battery negative electrode material composed of lithium-silicon alloy and lithium fast ion conductor lithium borate-lithium sulfate coated on the surface of lithium-silicon alloy, and the electrolyte diaphragm material is lithium nitrate-potassium nitrate- Magnesium oxide material.

[0042] The preparation method of above-mentioned high-voltage thermal battery is:

[0043] (1) Cathode material MnO 2 preparation

[0044] Take 1.5mmol of MnSO 4 ·H 2 O was dissolved in deionized water, and then 3 mmol of KMnO 4 dissolved in deionized wa...

Embodiment 3

[0054] A negative electrode material for a high-voltage thermal battery, which is composed of a lithium-silicon alloy and lithium fast ion conductor lithium borate-lithium sulfate coated on the surface of the lithium-silicon alloy; the lithium fast ion conductor lithium borate-lithium sulfate is added in an amount of 10% by weight; lithium fast ion conductor lithium borate-lithium sulfate is prepared by mixing lithium borate crystals and lithium sulfate anhydrous lithium crystals, the mass percentage of lithium borate crystals is 30%; the mass percentage of anhydrous lithium sulfate crystals is 70% %.

[0055] The preparation method of the above-mentioned lithium fast ion conductor lithium borate-lithium sulfate is:

[0056] 1) Analyzing the pure grade LiOH·H from the raw material 2 O and H 3 BO 3 respectively in Al 2 o 3 The crucible was treated at a constant temperature of 500 °C for 1 h, and then the two were sintered at a high temperature of 600 °C for 2 h in an air a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com