Biochar-chitosan composite as well as preparation method and application thereof

A composite material and biochar technology, applied in the field of material science and engineering, can solve the problems of difficult adsorption efficiency and low adsorption capacity, and achieve the effect of obvious adsorption effect, large adsorption capacity and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

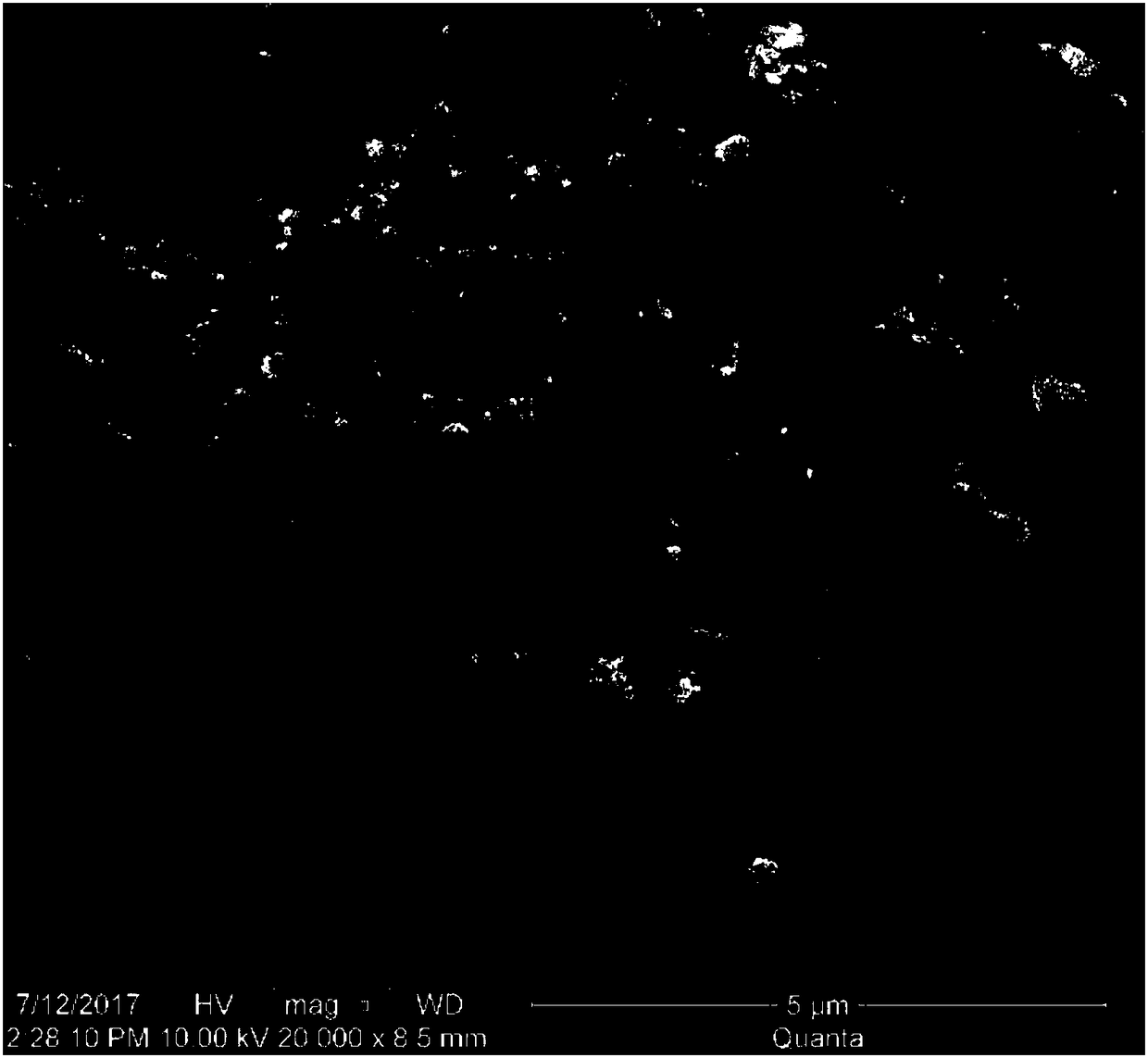

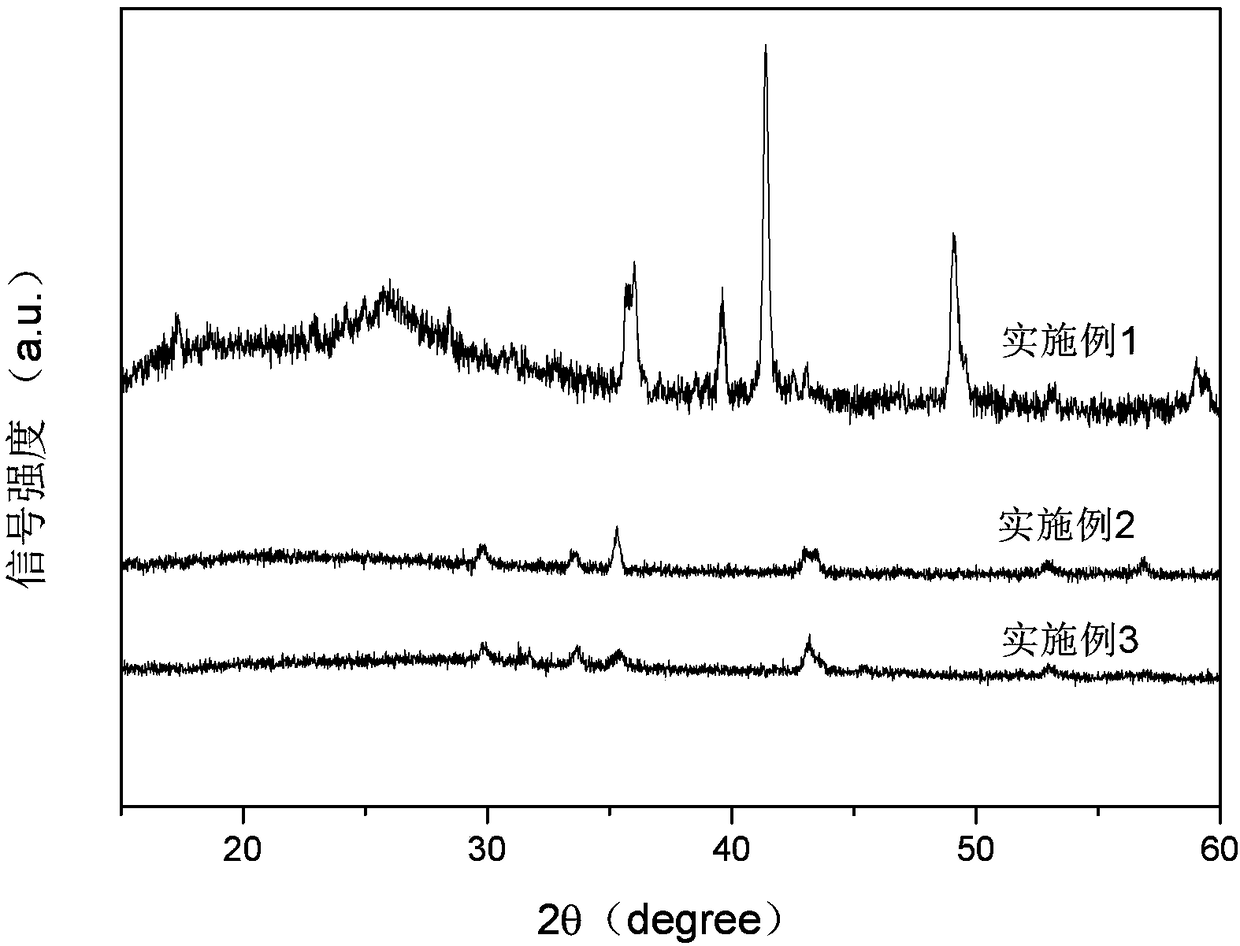

Embodiment 1

[0025] Get 10g of pulverized loofah and 200ml of 1.0mol / L FeCl 3 ﹒ 6H 2 O was mixed, and then the sulfuric acid of 0.98mol / L of 50ml was added. The resulting mixture was sonicated for 2 hours at a frequency of 100 KHz, filtered after mixing, and then dried in a vacuum oven for 12 hours (70° C.) to obtain the primary product of biochar material BC. The primary product was heated to 700°C under a nitrogen atmosphere, pyrolyzed for 2 hours, and washed repeatedly until neutral to obtain biochar material L-Fe. First dissolve 2g of chitosan powder in acetic acid of 1.75mol / L (purity 98%), add 2g of biochar material L-Fe sample to the above-mentioned acetic acid and chitosan mixture, and put the compound in a water bath Heat and stir (60°C, 2h) until well mixed. Afterwards, NaOH solution was added dropwise to the mixture until pH = 9, and the compound was continued to be stirred. Finally, the insoluble matter in the solution was filtered, washed, and dried (80° C., 8 h) for late...

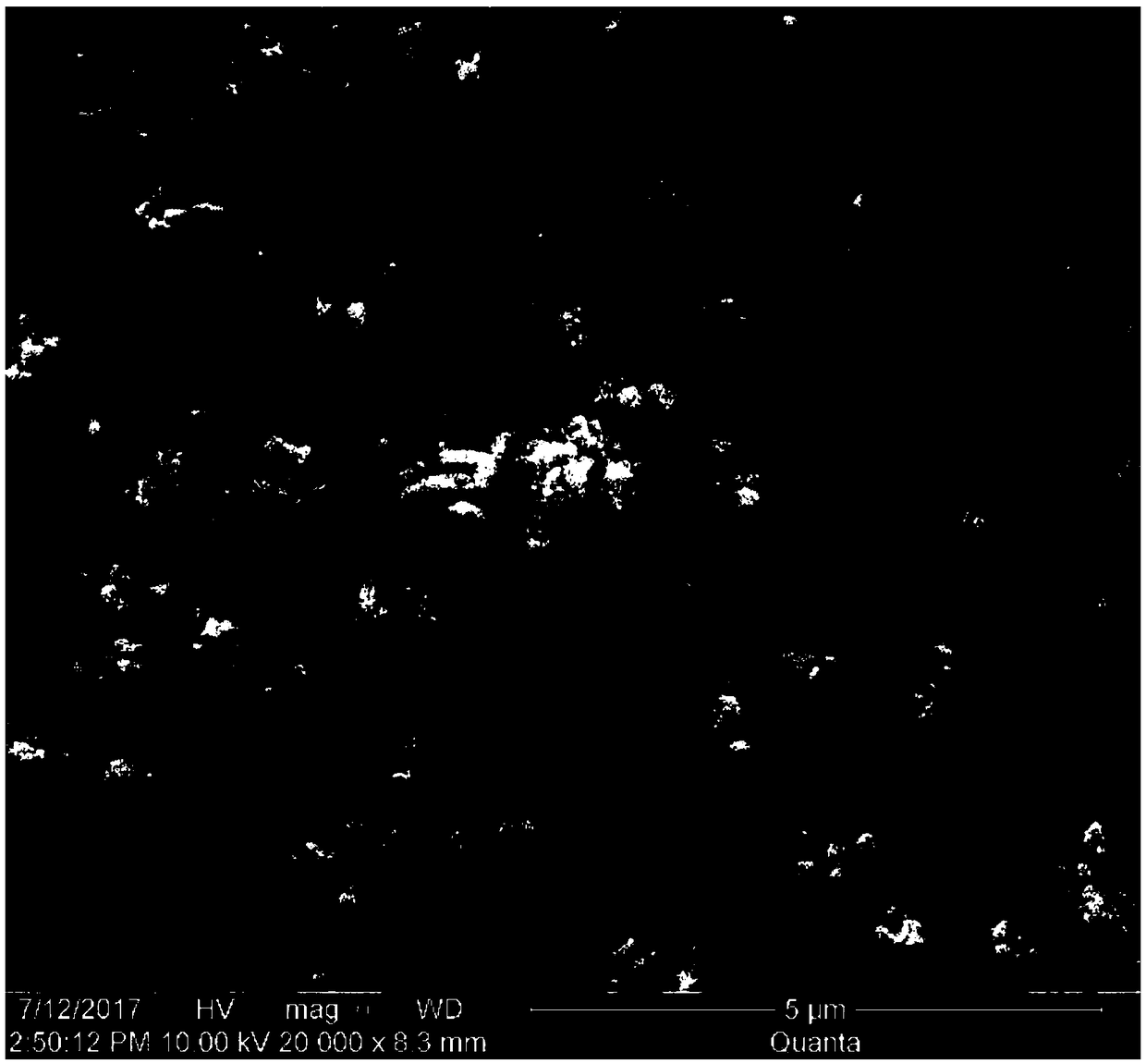

Embodiment 2

[0027] Get 10g of pulverized loofah and 300ml of 1.0mol / L FeCl 3 ﹒ 6H 2 O was mixed, and then added the sulfuric acid of 0.98mol / L of 100ml. The resulting mixture was sonicated for 2 hours at a frequency of 100 KHz, filtered after mixing, and then dried in a vacuum oven for 12 hours (100° C.) to obtain the primary product of biochar material BC. The primary product was heated to 700°C under a nitrogen atmosphere, pyrolyzed for 2 hours, and washed repeatedly until neutral to obtain biochar material L-Fe. First dissolve 1g of chitosan powder in acetic acid of 1.75mol / L (98% purity), add 2g of biochar material L-Fe sample to the above-mentioned acetic acid and chitosan mixture, and place the compound in a water bath Heat and stir (60°C, 2h) until well mixed. Afterwards, NaOH solution was added dropwise to the mixture until pH = 9, and the compound was continued to be stirred. Finally, the insoluble matter in the solution was filtered, washed, and dried (80° C., 8 h) for late...

Embodiment 3

[0029] Get 10g of pulverized loofah and 200ml of 1.0mol / L FeCl 3 ﹒ 6H 2 O was mixed, and then added the sulfuric acid of 0.98mol / L of 100ml. The resulting mixture was ultrasonically treated at a frequency of 100KHz for 2h, mixed and filtered, and then dried in a vacuum oven for 12h (50°C) to obtain the primary product of biochar material BC. The primary product was heated to 700°C under a nitrogen atmosphere, pyrolyzed for 2 hours, and washed repeatedly until neutral to obtain biochar material L-Fe. First dissolve the chitosan powder of 0.75g in the acetic acid of 1.75mol / L (purity 98%), add 1g biochar material L-Fe sample to above-mentioned acetic acid, chitosan mixed solution, and compound in the water bath Heat and stir (60°C, 2h) in medium until fully mixed. Afterwards, NaOH solution was added dropwise to the mixture until pH = 9, and the compound was continued to be stirred. Finally, the insoluble matter in the solution was filtered, washed, and dried (80° C., 8 h) f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com