PVC (polyvinyl chloride) functionalized master batch, preparation method and PVC-indole grafted blended product

A functional masterbatch technology, applied in the field of masterbatch preparation, indole functionalized polyvinyl chloride, can solve the problems of PVC aging degradation, process performance decline, high melt viscosity, etc., to improve tensile strength and fracture Elongation, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

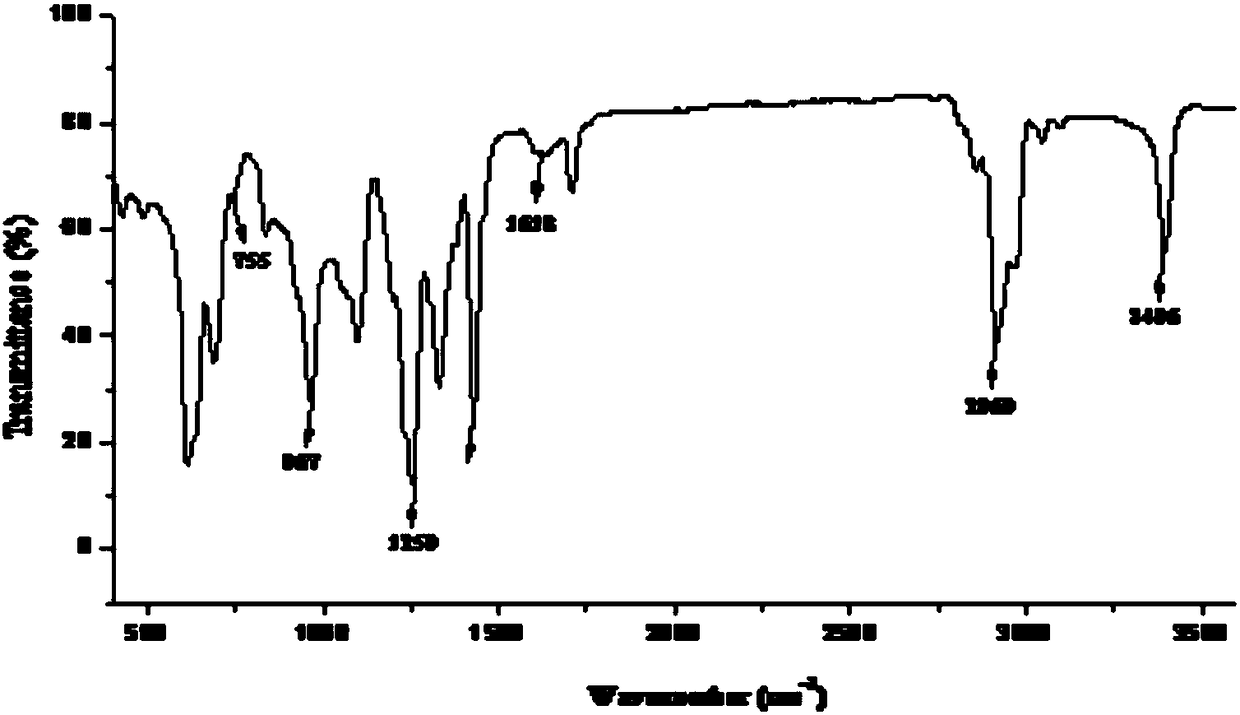

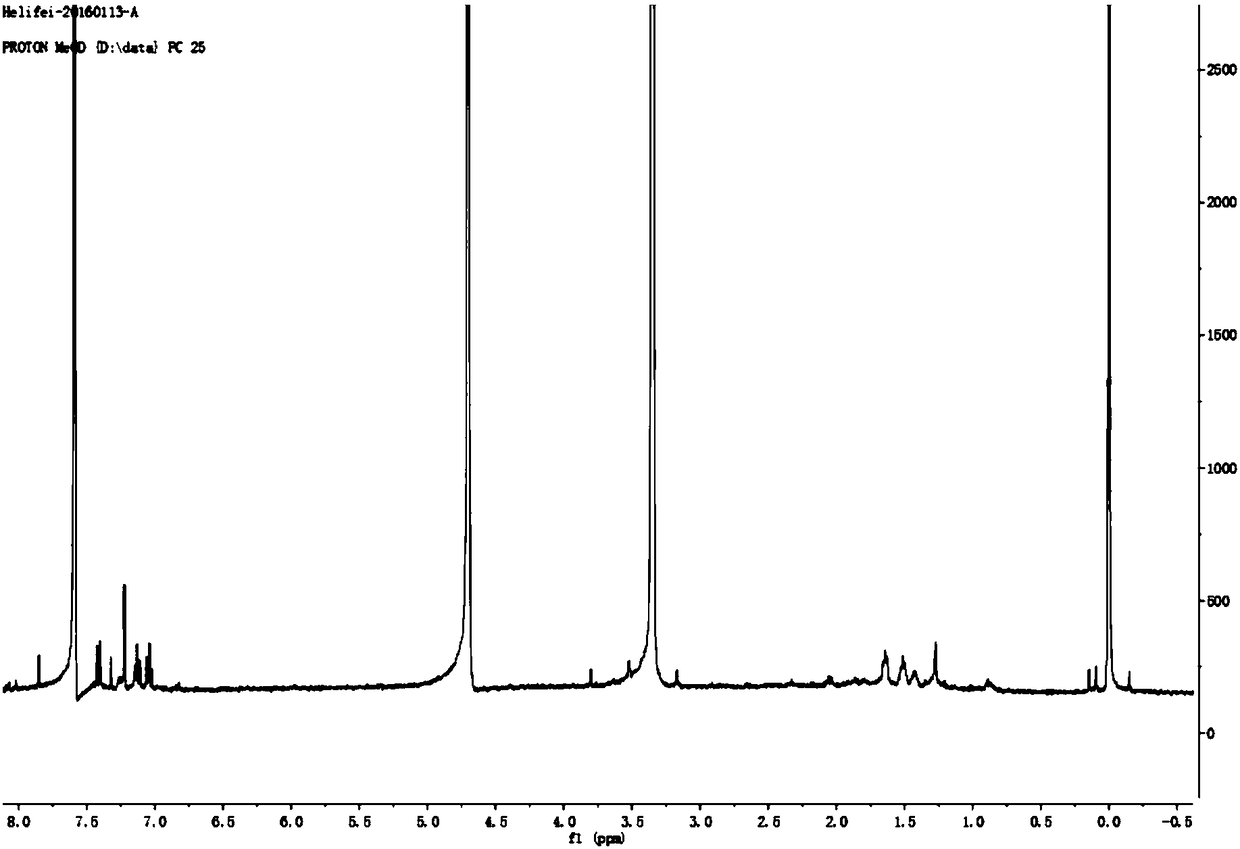

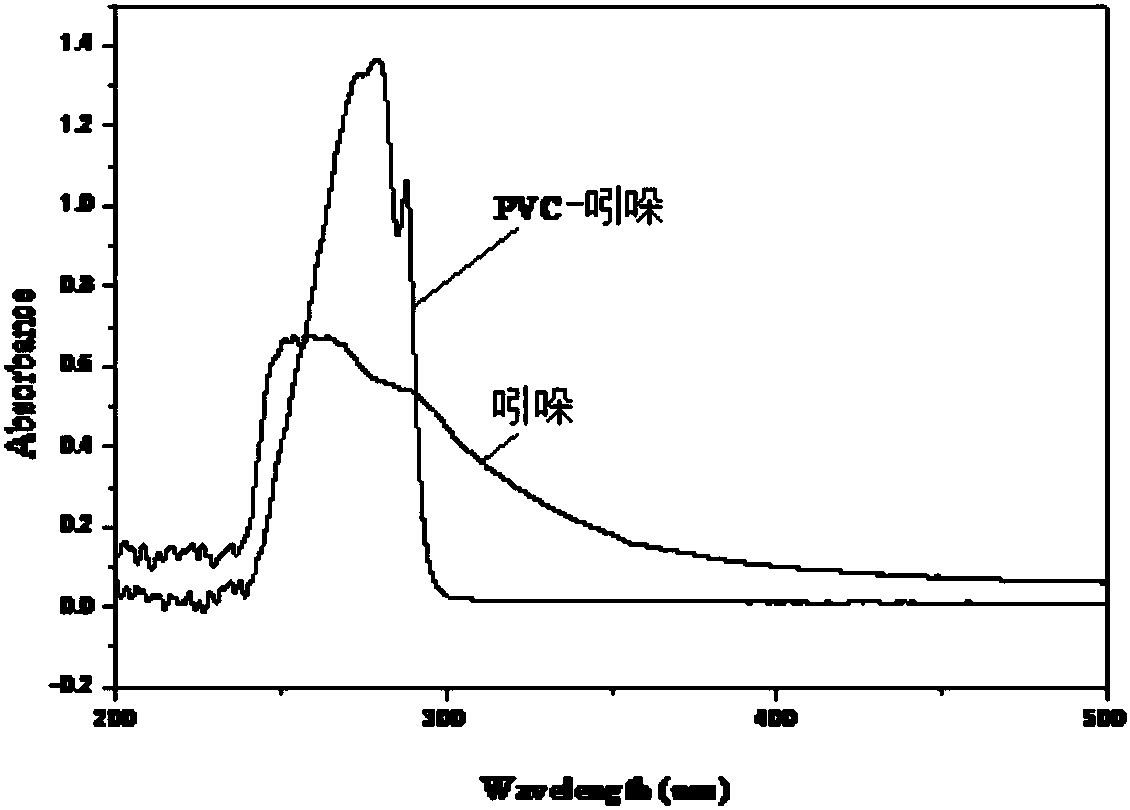

[0041] Dissolve 100g of PVC, 50g of indole, and 7g of anhydrous aluminum chloride in tetrahydrofuran solvent, and keep stirring to make them evenly mixed. Then, the reactant was placed in a microwave reactor, irradiated by 400W microwave at a reaction temperature of 65° C., and reacted for 15 minutes. Purification is carried out after the reaction is completed to obtain a PVC-g-indole graft, and the measured grafting rate reaches 1.93%. Congo red test was carried out on the product, which showed that the thermal stability time was 360s.

Embodiment 2

[0043] Dissolve 100g of PVC, 50g of indole, and 7g of anhydrous aluminum chloride in tetrahydrofuran solvent, and keep stirring to make them evenly mixed. The reactor was heated with an oil bath, the reaction temperature was 65°C, and the reaction was carried out for 15 minutes. Purification is carried out after the reaction is completed to obtain a PVC-g-indole graft, and the measured grafting rate reaches 0.83%. Congo red test was carried out on the product, which showed that the thermal stability time was 300s.

Embodiment 3

[0045] Dissolve 100g of PVC, 50g of indole, and 7g of anhydrous aluminum chloride in o-dichlorobenzene solvent, and keep stirring to make it evenly mixed. Then, the reactant was placed in a microwave reactor, irradiated by 400W microwave at a reaction temperature of 65° C., and reacted for 15 minutes. After the reaction is finished, purification treatment is carried out to obtain a PVC-g-indole graft, and the measured grafting rate reaches 0.88%. Congo red test was carried out on the product, which showed that the thermal stability time was 247s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com