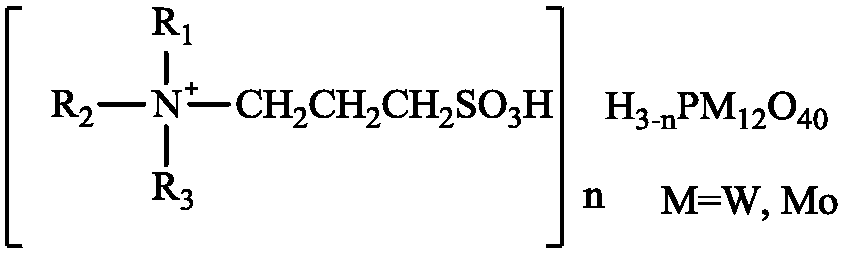

Method for catalyzing fuel oil desulfurization by coupling of sulfonic heteropolyacid salt with eutectic solvent

A technology of deep eutectic solvent and heteropolyacid salt, which is applied in the field of desulfurization to achieve the effects of mild reaction conditions, simple operation and simple synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] Preparation of sulfonic acid heteropoly salt catalyst: Add 0.1mol 1,3-propane sultone into a beaker of 50mL dichloromethane, stir for 10min under an oil bath atmosphere; then add 0.1mol triethylamine dropwise Add it to the above mixture and react at 40°C for 24h. After the reaction, filter, wash with ethyl acetate and ether, and dry in an oven at 100°C to obtain the product PSTEtA. The product PSTEtA was added to the phosphotungstic acid solution, wherein the molar ratio was n:1, stirred for 24 hours, and the final product was placed in an oven for 8 hours. [TBAC] 3 PW 12 o 40 Using the above synthesis [PSTEtA] n h 3-n PW 12 o 40 Prepared by the method, wherein TBAC and H 3 PW 12 o 40 The molar ratio is 3:1. For the synthesis of the remaining catalysts, refer to the above synthesis methods.

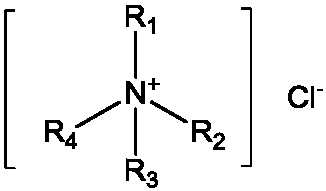

[0038] Preparation of choline-based deep eutectic solvent: Mix the quaternary ammonium salt and the hydrogen bond donor together to obtain a uniformly mixed liquid, and ...

Embodiment 1

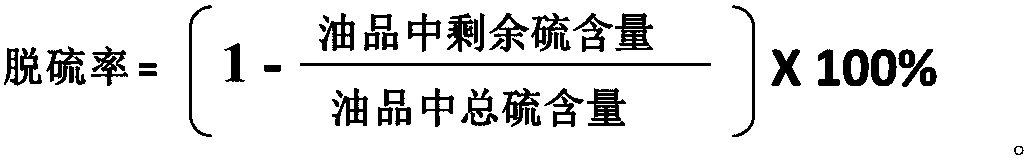

[0044] Add 5mL DBT model oil (the sulfur content of oil product is 500ppm) in the 50mL round bottom flask, then add the catalyst [PSTEtA]H of 0.01g above-mentioned preparation 2 PW 12 o 40 , 1 mL deep eutectic solvent ChCl / 2Ac, 0.156 mmol H 2 o 2 , the mass fraction is 30%. At this time, the oil phase was in the upper layer, stirred and reacted at 1000rpm at 50°C for 2.5h, the model oil was separated, and the content of DBT in the oil was detected by GC-FID (internal standard method), and the removal rate of sulfur was calculated to be 96.0%.

Embodiment 2

[0046] Add 5mL DBT model oil (the sulfur content of oil product is 500ppm) in 50mL round bottom flask, then add 0.01g above-mentioned prepared catalyst [PSTEtA] 3 PW 12 o 40 , 1 mL deep eutectic solvent ChCl / 3Ac, 0.234 mmol H 2 o 2 , the mass fraction is 30%. At this time, the oil phase was in the upper layer, stirred and reacted at 800rpm at 60°C for 2h, the model oil was separated, and the content of DBT in the oil was detected by GC-FID (internal standard method), and the removal rate of sulfur was calculated to be 99.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com