Substrate Controlled Step Morphology Pretreatment Method for Graphene Prepared by Pyrolysis of Silicon Carbide

A technology of silicon carbide substrate and graphene, which is applied in the manufacture of graphene, nano-carbon, semiconductor/solid-state devices, etc., can solve the problem that the steps on the surface of the substrate are difficult to control, etc., achieve the simple and easy pretreatment method, and expand the process window , the effect of high promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

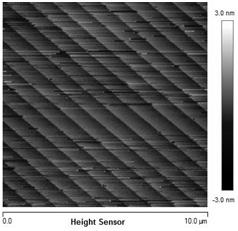

Image

Examples

Embodiment 1

[0035] A substrate controllable step morphology pretreatment method applied to the pyrolysis of silicon carbide to prepare graphene, comprising the following steps:

[0036](1) Place the cleaned positive crystal orientation, high-purity semi-insulating 4H-SiC substrate on the base in the chemical vapor deposition CVD equipment.

[0037] (2) set reaction chamber pressure as 90 mbar, hydrogen (H 2 ) The flow rate is 90L / min, and the temperature of the system is raised to 1420°C.

[0038] (3) Keep the pressure and H 2 The flow rate is kept constant, and the temperature is continued to be raised to an etching temperature of 1550° C., and a carbon source of 2 sccm is introduced to assist etching at the same time during the heating stage.

[0039] (4) After heating up to the etching temperature of 1550°C, keep the pressure, temperature and H 2 The flow rate is constant, and the carbon source flow rate adopted in step (3) is slowly increased to 40 sccm in a linear slow-changing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com