Unilateral MOS-type device manufacturing method integrated with SBD structure

A device and range technology, applied in the field of single-side MOS device preparation with integrated SBD structure, can solve the problems of device application cost increase, achieve the effects of reducing the original cell size, improving device conduction ability, and reducing application cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

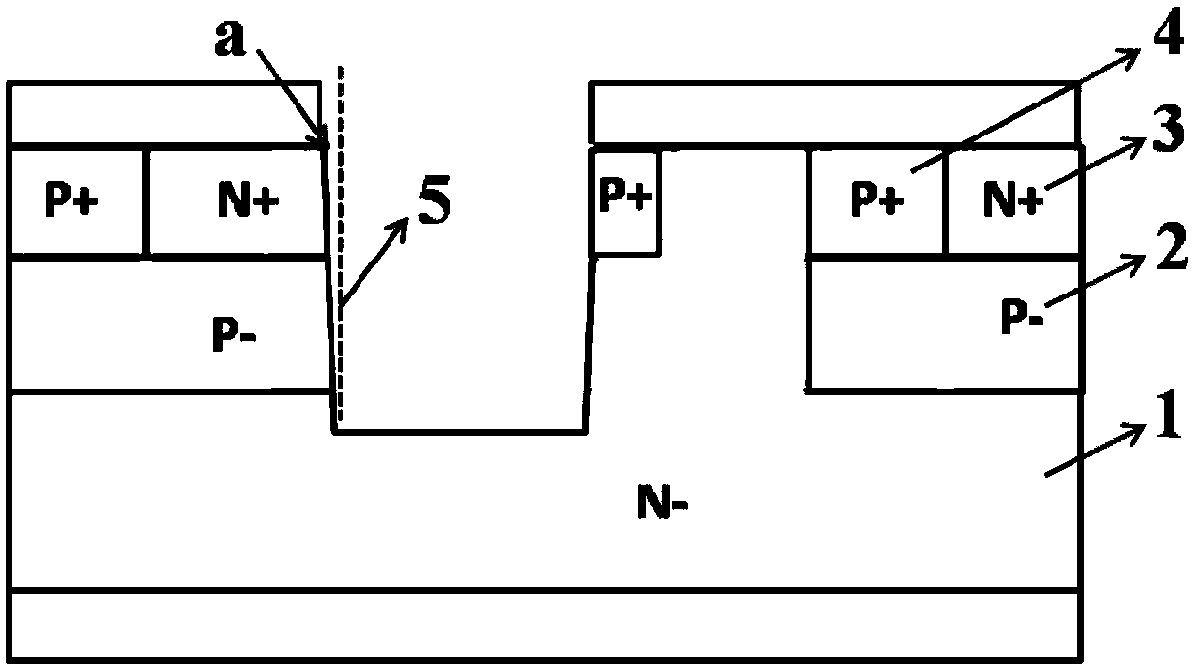

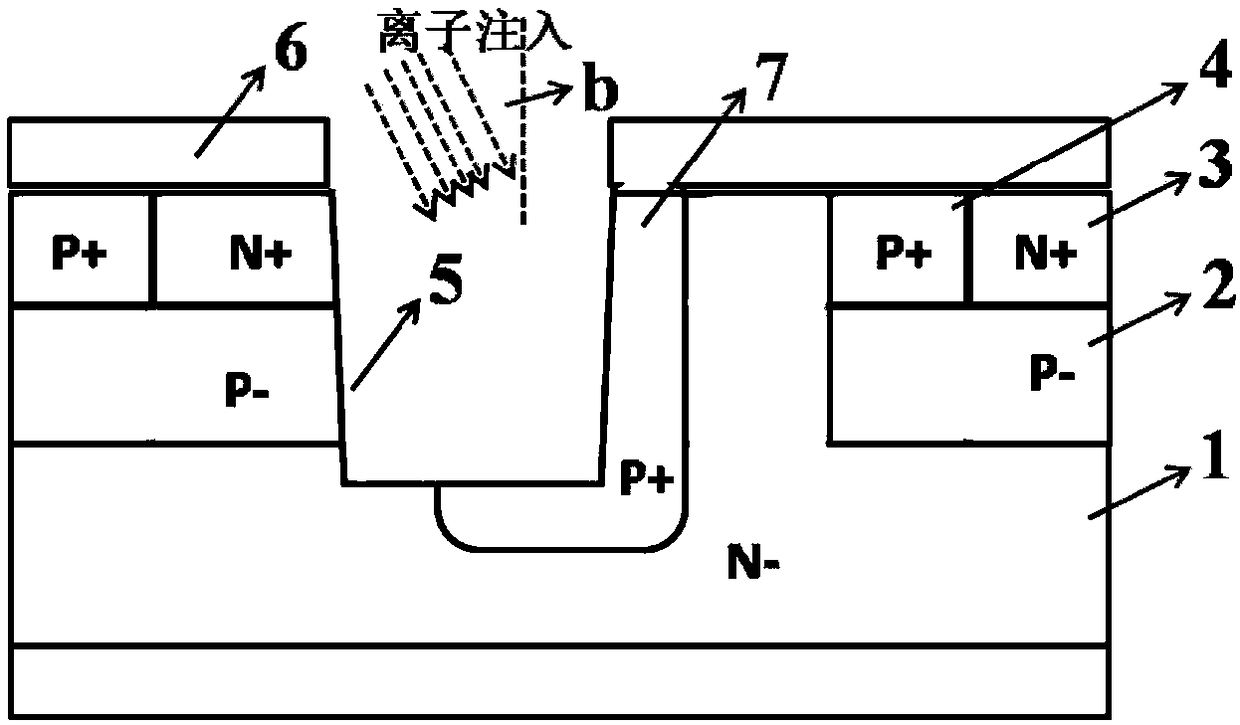

[0022] The present invention provides a novel method for preparing a silicon carbide single-side trench MOS device with an integrated SBD structure through trench etching, oblique angle implantation, front-side ohmic metal and Schottky metal compatible technology, which specifically includes the following steps :

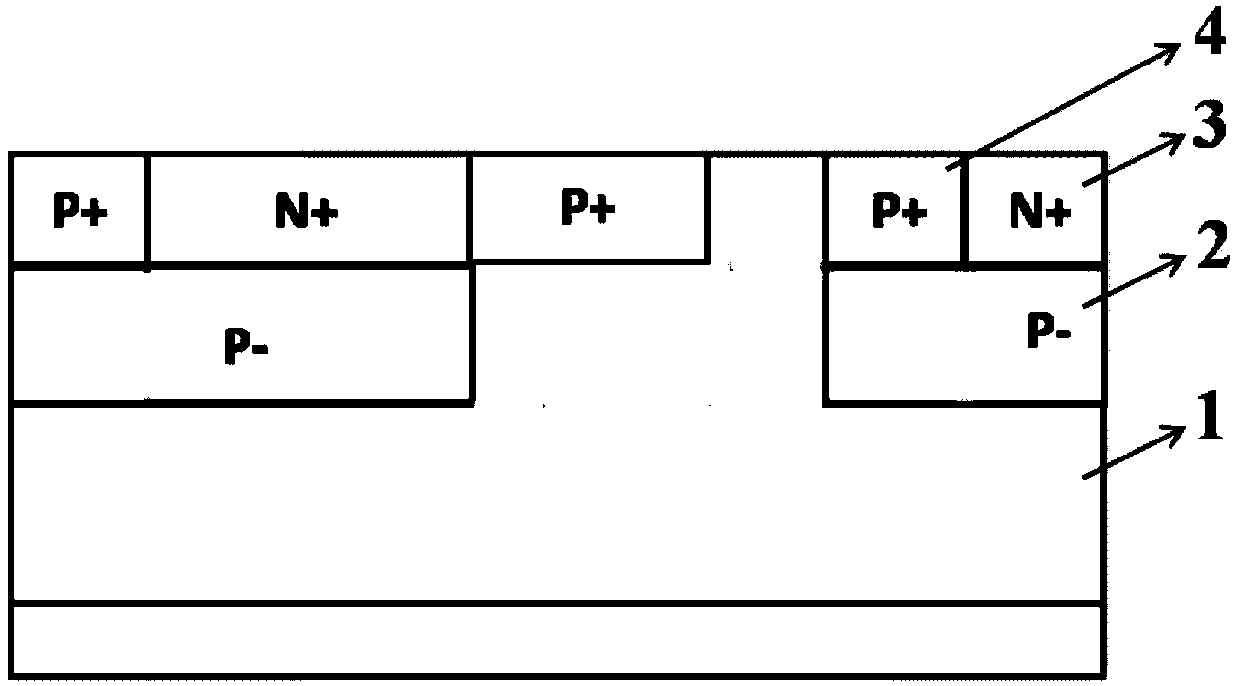

[0023] (1) On the silicon carbide epitaxial layer 1, a plurality of P-Well ion implantation regions 2, N+ ion implantation regions 3, and P+ ion implantation are formed through multiple processes such as growing a dielectric mask, photolithography, etching, and ion implantation Zone 4, such as figure 1 As shown, the doping area, doping concentration and doping distribution can be precisely controlled to realize the substrate material of monolithic integrated silicon carbide MOSFET and SBD structure.

[0024] The i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com