Ruthenium water oxidation catalyst based on electronegative ligand and preparation method thereof

An oxidation catalyst and electronegative technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problem of insufficient stability and fast decay rate of catalytic current density etc. to achieve good photoelectrochemical performance, simple preparation method and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

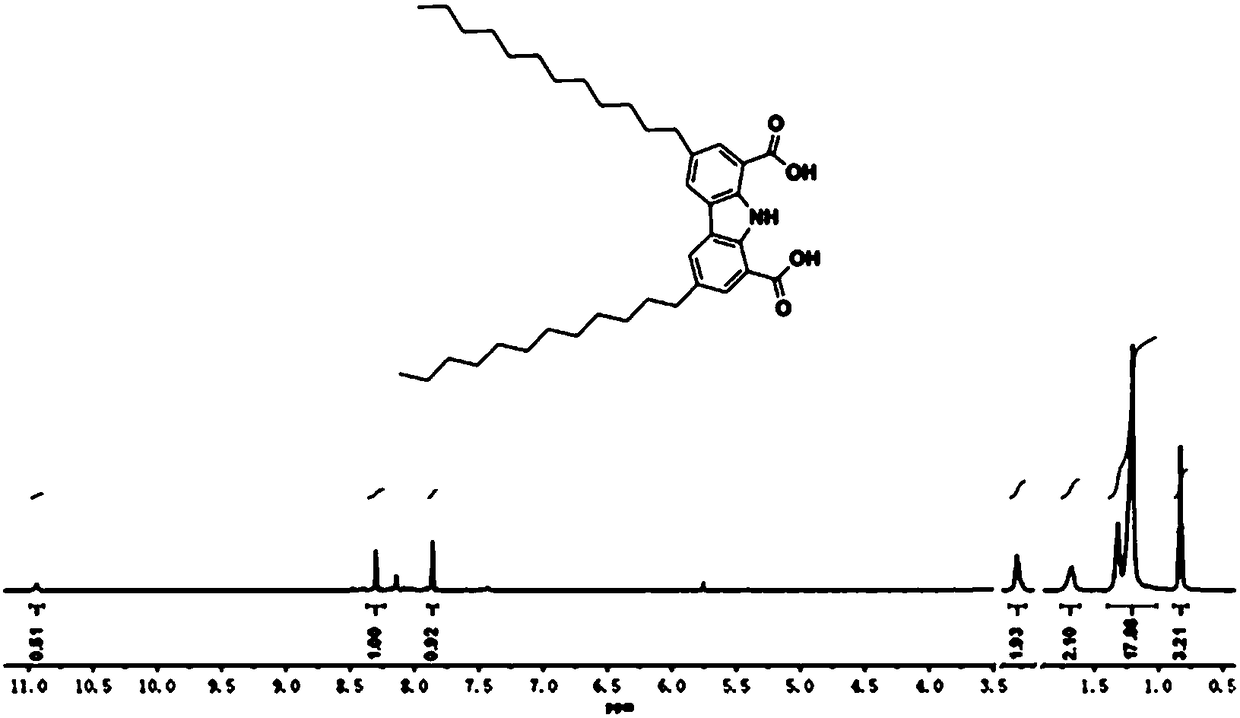

[0031] The preparation of embodiment 1 carbazole derivative I

[0032]

[0033] Add carbazole (5.02g, 30mmol) and 100mL CH to a 250mL two-necked bottle 2 Cl 2 , added anhydrous aluminum trichloride (9.33g, 70mmol) in batches under stirring at room temperature, continued stirring for 90 minutes, cooled the reaction to 0°C in an ice-water bath, slowly added dodecanoyl chloride (15.30g, 70mmol) dropwise ), after the dropwise addition, the reaction temperature was raised to room temperature, and the stirring reaction was continued for 14 hours. The reaction solution was poured into 200mL ice water, the precipitate was collected by filtration, rinsed with deionized water and methanol respectively, the crude product was collected and recrystallized with methanol / acetone, and dried in vacuo to obtain white pure product 3,6-bis(dodecanoyl) Carbazole (11.20 g, 70% yield). 1 H NMR (400MHz, CDCl 3 ,): δ (ppm) 8.98 (br, 1H), 8.79 (s, 2H), 8.14 (d, J = 8.8Hz, 2H), 7.49 (d, J = 8.8Hz...

Embodiment 2

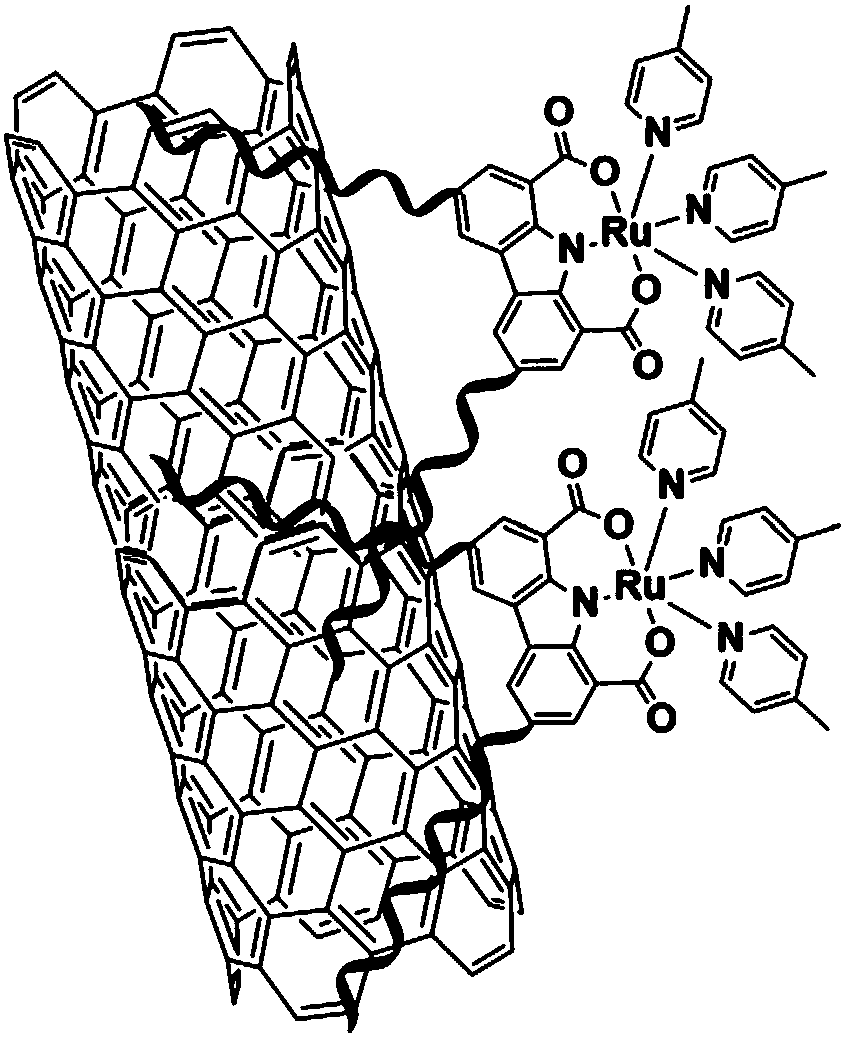

[0038] Example 2 Preparation of Metal Complex Ru with Carbazole Dicarboxylic Acid Derivatives as Skeleton

[0039]

[0040] Compound Ⅰ and Ru(DMSO) 4 Cl 2 in Et 3 N and anhydrous DMF, heated to 110 ° C for 12 h. Then 4-picoline was added, and the reaction was continued at 90°C for 10 hours. The reaction was stopped, cooled to room temperature, and the solvent was spin-dried to obtain a dark green powder product. Compound Ⅰ and Ru(DMSO) 4 Cl 2 The molar ratio of 1:1, 4-picoline is in excess. The above steps are all carried out under anhydrous and oxygen-free conditions.

[0041] Finally, with CH 2 Cl 2 / CH 3 OH=100:1 (V:V) was used as the eluent for silica gel column separation to obtain a green solid product (yield 45%). TOF-MS: m / z=[M+H] + calcd:970.4910;found,970.4941.m / z=[M+Na] + calcd:992.4730;found:992.4754.Elem.anal:calcd.for C 56 h 75 N 4 o 4 Ru(%): C 69.32, H 7.74, N 5.78; found, C 69.23, H 7.72, N 5.88.

Embodiment 3

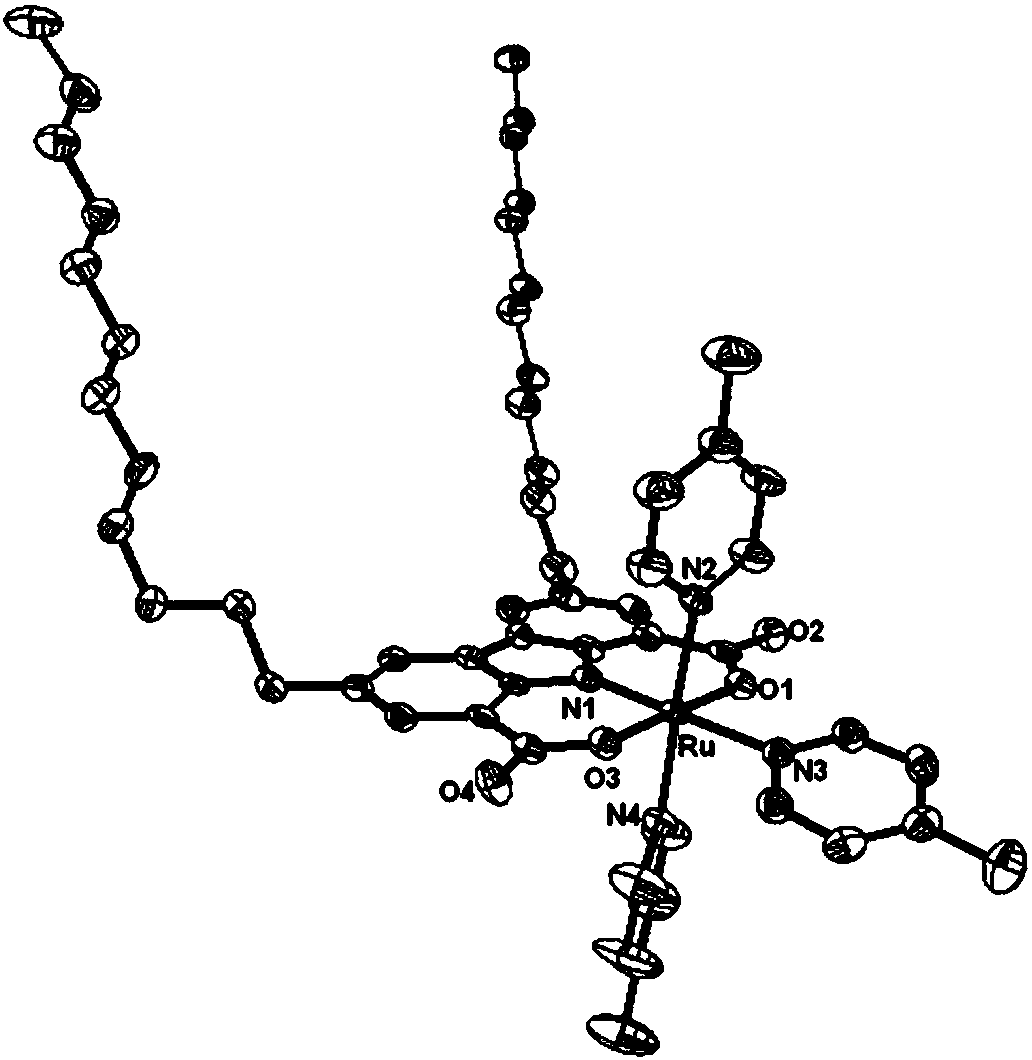

[0042] Crystal growth and analysis of embodiment 3 metal complex Ru

[0043] The crystal cultivation method of the complex: Slowly add 0.1 mL of deionized water to 5 mL of the methanol solution in which the complex (15 mg) is dissolved, store it in a sealed container, and let it stand at room temperature for five days. The entire system is supersaturated through the interdiffusion of methanol and water , a green crystal suitable for single crystal testing was precipitated.

[0044] The structure of the complex was tested by X-ray single crystal diffraction, and its X-ray single crystal diffraction data were obtained. For specific test instruments and methods, see Section 2.2.3 of Chapter II. The crystallographic parameters and test parameters of the complexes are listed in Table 1.

[0045] Table 1 Crystal test data and related parameters of complex Ru

[0046]

[0047] Through the X-ray single crystal diffraction test, the precise spatial structure of the complex Ru was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com