A modification method of highly dispersed rubber filler carbon nanotubes

A technology of carbon nanotubes and rubber fillers is applied in the field of high dispersity preparation of solution-polymerized styrene-butadiene rubber filler carbon nanotubes. , the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

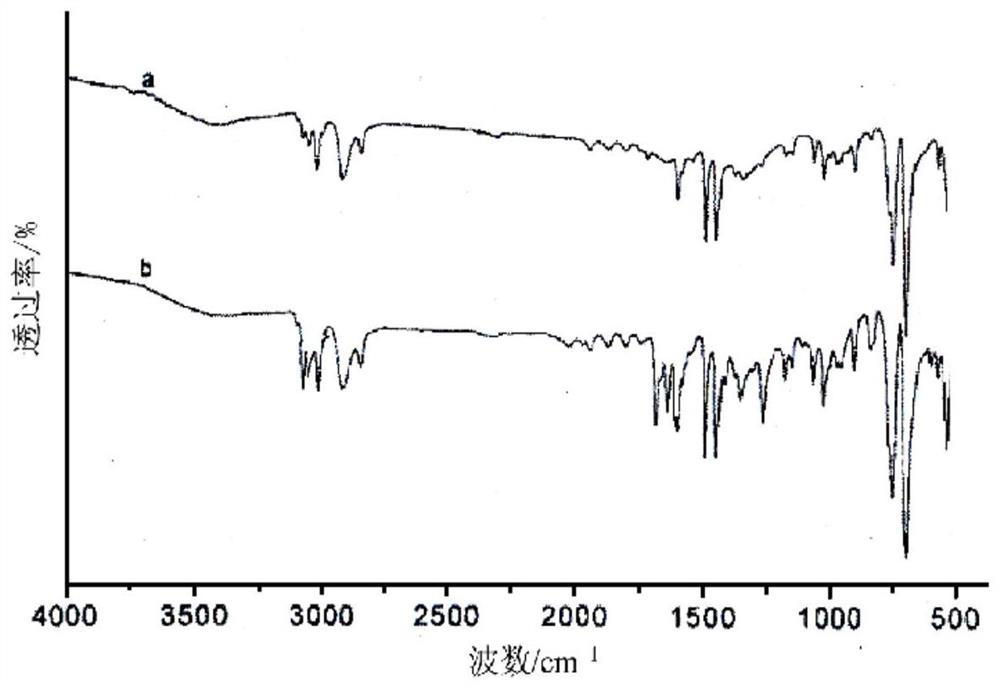

Image

Examples

Embodiment 1

[0033] (1) Preparation of amination of carbon nanotubes: 100 parts of carbon nanotubes, 150 parts of concentrated nitric acid, 50 parts of concentrated sulfuric acid, and 10 parts of potassium permanganate are mixed in a reactor, treated with 50 kHz ultrasonic waves for 1 hr, and then Heat to 50°C, stir and cook with acid for 2 hours, cool, filter, and wash until the filtrate is neutral, then add 200 parts of hexamethylenetetramine, then heat to 70°C, stir for 2 hours, filter with suction, wash, and dry. The carbon nanotube a with amine groups on the surface is obtained.

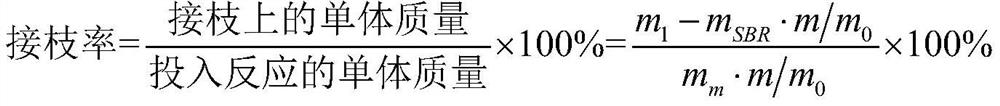

[0034] (2) Preparation of grafted solution-polymerized styrene-butadiene mortar: first add 300 parts of cyclohexane in the polymerization kettle, then add 100 parts of solution-polymerized styrene-butadiene mortar SSBR2564s, 0.05 part of tert-dodecyl mercaptan in sequence, and use nitrogen gas to After the replacement, add 1 part of methacrylamide, stir and heat, add 0.05 part of DCP when the temperature of ...

Embodiment 2

[0037] (1) Preparation of carbon nanotube amination: same as Example 1.

[0038] (2) Preparation of grafted solution-polymerized styrene-butadiene mortar: with embodiment 1.

[0039] (3) Preparation of highly dispersed carbon nanotubes: 100 parts of aminated carbon nanotubes a and 350 parts of cyclohexane were added to the polymerization kettle and stirred for 15 minutes; , stirred and heated to 60° C., stirred and reacted for 3 hours, and then flashed, dried, and ground to obtain highly dispersed carbon nanotubes. Sampling and analysis: standard samples were made, and the tested properties are shown in Table 1.

Embodiment 3

[0041] (1) Preparation of carbon nanotube amination: put 100 parts of carbon nanotubes, 180 parts of concentrated nitric acid, 70 parts of concentrated sulfuric acid, and 30 parts of potassium permanganate into a reactor and mix them with 80 kHz ultrasonic treatment for 1.5 hr. Then heat to 70°C, stir and cook with acid for 5hr, cool, filter with suction, wash until the filtrate is neutral, add 300 parts of hexamethylenetetramine, heat to 80°C, stir for 3hr, filter with suction, wash and dry , to obtain carbon nanotubes b with amine groups on the surface.

[0042] (2) Preparation of grafted solution-polymerized styrene-butadiene mortar: first add 450 parts of cyclohexane in the polymerization kettle, then add 100 parts of solution-polymerized styrene-butadiene mortar SSBR2564s, 0.3 part of tert-dodecyl mercaptan in sequence, and use nitrogen gas to After the replacement, add 7 parts of methacrylamide, stir and heat, add 0.1 part of DCP when the temperature of the polymerizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com