Antibacterial cleaning product and preparation method thereof

A cleaning product, mass percentage technology, applied in the field of sanitary products, can solve the problems of complex preparation process, high production cost, and many antibacterial components of antibacterial soap, and achieve good decontamination effect, low production cost, and high antibacterial activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The preparation of embodiment 1 hemp extract

[0046] Process:

[0047] 1. Wash and air-dry the raw material cannabis stalks, cannabis flowers, cannabis leaves and / or cannabis roots;

[0048] 2. Crush the air-dried raw materials to 10-40 mesh;

[0049]3. The obtained powder is cold soaked and extracted with 4-8 times the amount of 30%-60% ethanol for 1-3 times, each time for 0.5-2 hours;

[0050] 4. Combine the extracts and decolorize them by adsorption of 0.1-1wt% activated carbon;

[0051] 5. Concentrate under reduced pressure to a relative density of 1.01-1.03 at a temperature of 70°C;

[0052] Cannabis extract extracts are obtained, such as cannabis stalk core extract, cannabis flower extract, cannabis leaf extract, cannabis root extract, or a combination of two, three or four of them.

[0053] The cannabis extract used in the following examples can be prepared by the method of Example 1, or by other extraction methods disclosed in the prior art.

Embodiment 2

[0054] The preparation of embodiment 2 product of the present invention

[0055] Process:

[0056] 1. Heat phase A to 80°C and mix evenly, heat phase B to 80°C and add to phase A, stir until saponification is complete.

[0057] 2. Then add phase C ingredients and mix well.

[0058] 3. After cooling down to 40°C, add phase D and stir evenly to obtain soap liquid.

[0059] 4. Use a brush to dip a small amount of olive oil to coat the inside of the mold, then pour the mixed soap into the mold, cover the mold with a plastic film, and place it in a 35°C incubator for 24-48 hours; after it solidifies, air-dry and demould, and then place Allow it to dry naturally for 4 weeks in a ventilated place in a normal temperature environment.

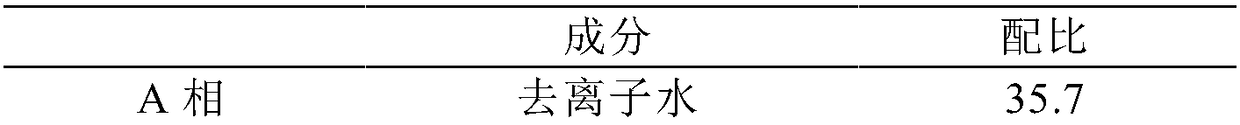

[0060] The composition and mass ratio of phases A, B, C, and D are shown in Table 1.

[0061] Table 1 Composition and composition of phases A, B, C, and D

[0062]

[0063]

Embodiment 3

[0064] The preparation of embodiment 3 products of the present invention

[0065] Process:

[0066] 1. Heat phase A to 70°C and mix evenly, heat phase B to 70°C and add to phase A, stir until saponification is complete.

[0067] 2. Then add phase C ingredients and mix well.

[0068] 3. After cooling down to 30°C, add phase D and stir evenly to obtain soap liquid.

[0069] 4. Use a brush to dip a small amount of olive oil to coat the inside of the mold, then pour the mixed soap into the mold, cover the mold with a plastic film, and place it in a 35°C incubator for 24-48 hours; after it solidifies, air-dry and demould, and then place Allow it to dry naturally for 4 weeks in a ventilated place in a normal temperature environment.

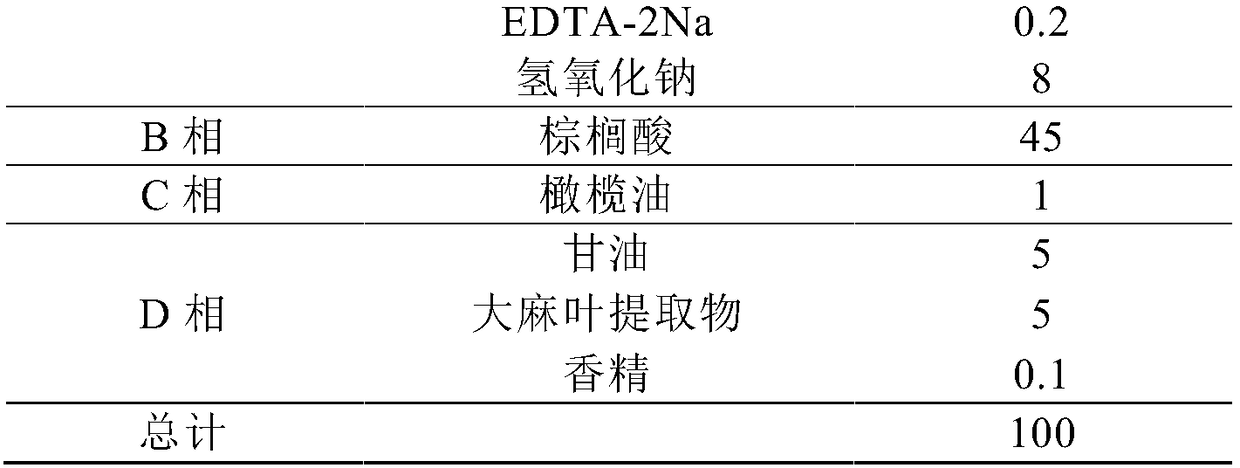

[0070] Wherein the composition and composition of A, B, C, and D phases are shown in Table 2.

[0071] Table 2 Composition and Composition of Phases A, B, C, and D

[0072]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com