Preparation method of Fe-doped Bi2O2CO3 photocatalyst and Fe-doped Bi2O2CO3 photocatalyst

A technology of photocatalyst and dopant, which is applied in the field of photocatalysis, can solve problems such as limitations, and achieve the effect of enhanced absorption and enhanced photocatalytic activity of visible light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides an Fe-doped Bi 2 o 2 CO 3 The preparation method of photocatalyst, it comprises: will contain Fe 3+ The dopant is dissolved in Bi(NO 3 ) 3 and sodium citrate in an alkaline organic solvent solution, and carry out hydrothermal reaction under the condition of ammonia water.

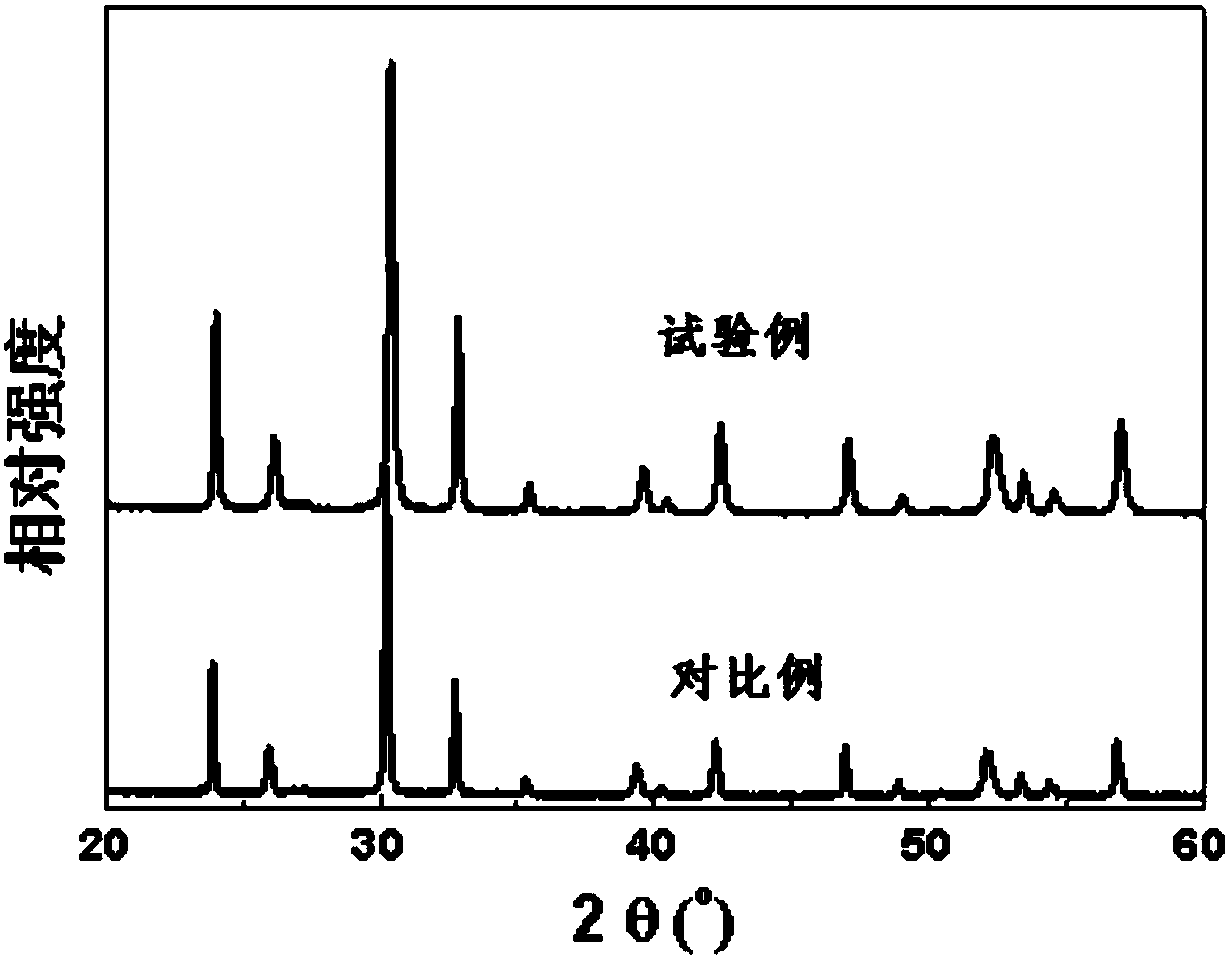

[0024] Bi 2 o 2 CO 3 It is a typical bismuth-based composite oxide composed of Bi 2 o 2 2+ and CO 3 2– Composition, its curved spatial structure exhibits unique photocatalytic properties under UV-visible light irradiation. The inventors found that the Fe 3+ doping into Bi 2 o 2 CO 3 In the crystal lattice, it can effectively increase the Bi 2 o 2 CO 3 The absorption of visible light, thus effectively improving the Bi 2 o 2 CO 3 visible light photocatalytic activity.

[0025] Contains Fe 3+ The dopant acts as an iron source, providing Fe 3+ Enter Bi 2 o 2 CO 3 in the lattice. In some specific embodiments of the present invention, containing Fe 3+ Th...

Embodiment 1

[0040] A Fe-doped Bi 2 o 2 CO 3 The preparation method of photocatalyst comprises:

[0041] S1, the 0.97gBi (NO 3 ) 3 and 0.3 g of sodium citrate were dissolved in 10 ml of N,N-dimethylformamide to obtain a reaction solution.

[0042] S2, add 0.1gFe(NO 3 ) 3 , stirred evenly, and 5ml of ammonia water with a mass concentration of 28% was added to obtain a reaction mixture.

[0043] S3. Transfer the reaction mixture to a hydrothermal kettle, keep it warm at 170° C. for 12 hours, and separate the solid and liquid after cooling to obtain the primary product.

[0044] S4. Wash the initial product alternately with distilled water and ethanol, and dry it at 60° C. for 8 hours to obtain Bi 2 o 2 CO 3 catalyst of light.

[0045] A kind of Fe-doped Bi prepared according to the above-mentioned preparation method 2 o 2 CO 3 catalyst of light.

Embodiment 2

[0047] A Fe-doped Bi 2 o 2 CO 3 The preparation method of photocatalyst comprises:

[0048] S1, put 0.8gBi(NO 3 ) 3 and 0.15 g of sodium citrate were dissolved in 8 ml of N,N-dimethylformamide to obtain a reaction solution.

[0049] S2, add 0.02gFe(NO 3 ) 3 , stirred evenly, and 3ml of ammonia water with a mass concentration of 35% was added to obtain a reaction mixture.

[0050] S3. Transfer the reaction mixture to a hydrothermal kettle, keep it warm at 175°C for 11 hours, and separate the solid and liquid after cooling to obtain the primary product.

[0051] S4. Wash the initial product alternately with distilled water and ethanol, and dry it at 60° C. for 8 hours to obtain Bi 2 o 2 CO 3 catalyst of light.

[0052] A kind of Fe-doped Bi prepared according to the above-mentioned preparation method 2 o 2 CO 3 catalyst of light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com