Method and device for preparing spherical titanium nitride powder

A titanium nitride and spherical technology, which is applied in the field of plasma powder production equipment to prepare spherical titanium nitride powder, can solve the problems of large energy loss and poor sphericity of titanium nitride, and achieve short reaction time, spheroidization rate and Increased nitriding rate and low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

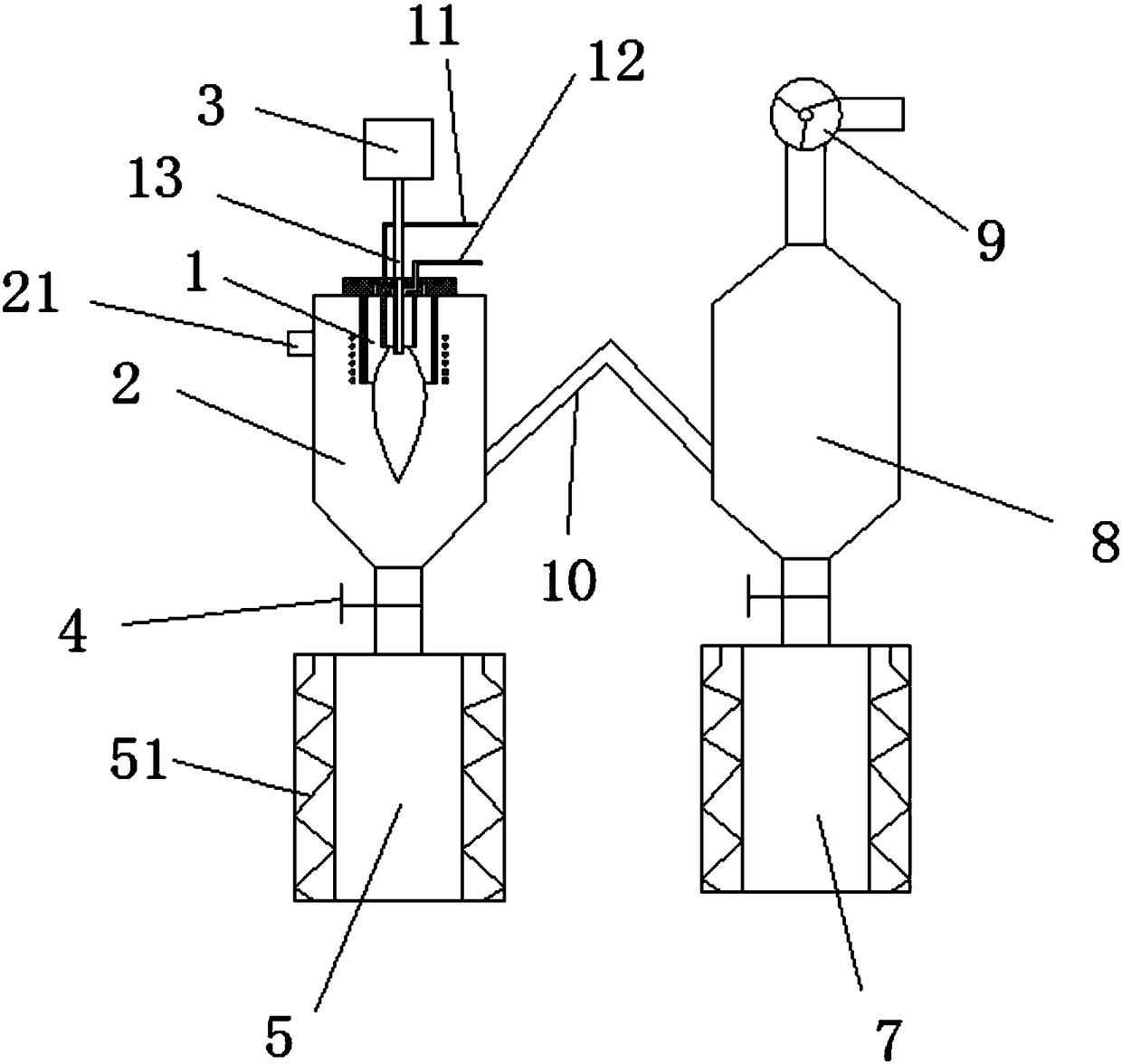

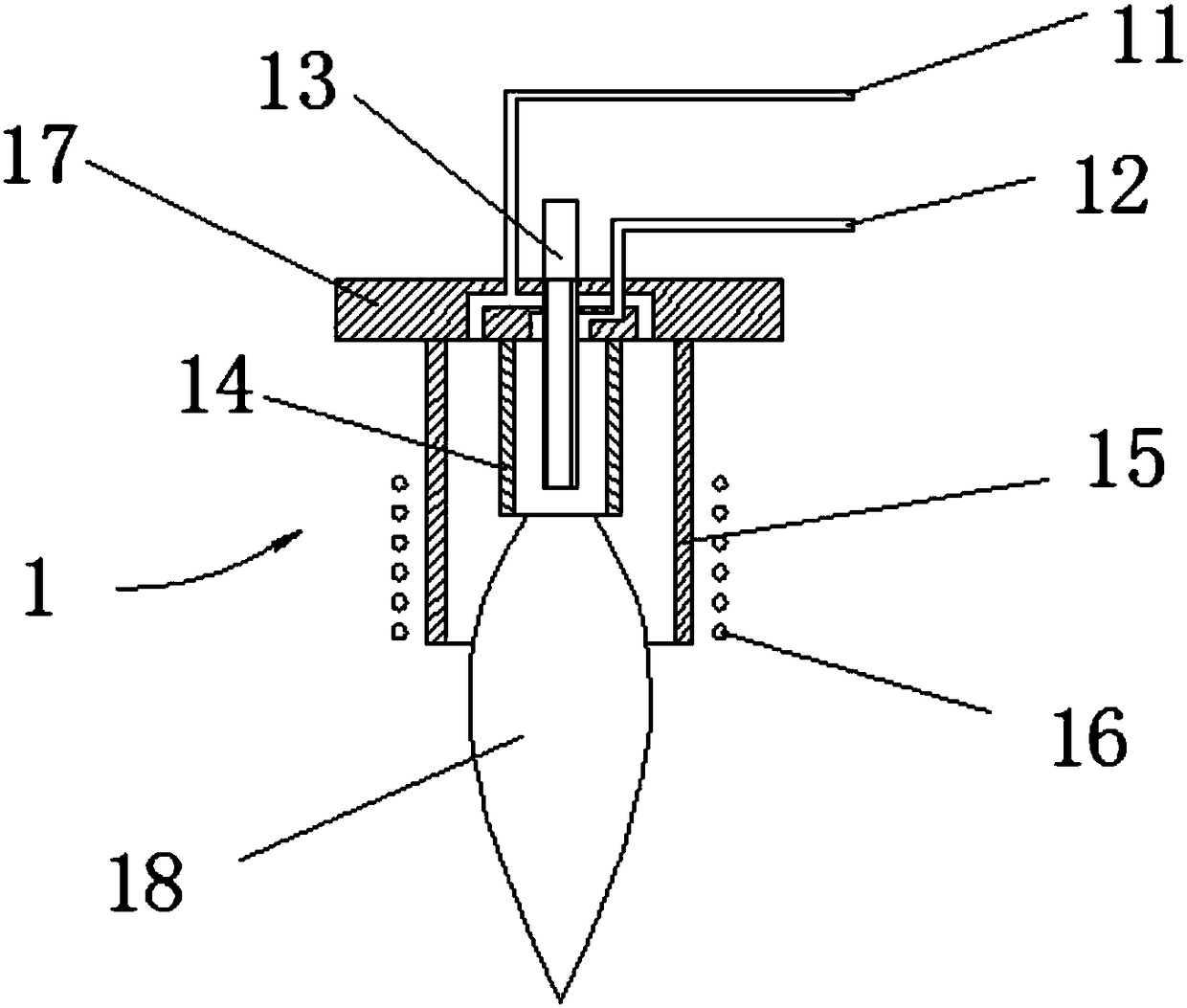

[0028] The preparation method of spherical titanium nitride of the present invention is prepared by radio frequency plasma equipment, and specifically comprises the following steps:

[0029] a. Arcing: Argon is used as the ionized gas to start the arc, and nitrogen is introduced from the protective gas inlet of the radio frequency plasma equipment at the same time; the operating voltage of the radio frequency plasma equipment is controlled to be 5-15kV, and the power is 30-200kW; among them, The flow rate of ionized gas is 1~10m3 / h, and the flow rate of nitrogen gas at the inlet of protective gas is 1~10m3 / h;

[0030] b. Feeding: After the arc is stable, the titanium powder is fed into the titanium powder by the feeding device, and the titanium powder is spheroidized in the plasma torch while being directly nitrided to obtain semi-molten titanium nitride; then the semi-molten titanium nitride is in the Under the action of surface tension, it cools and solidifies into a spheric...

Embodiment 1

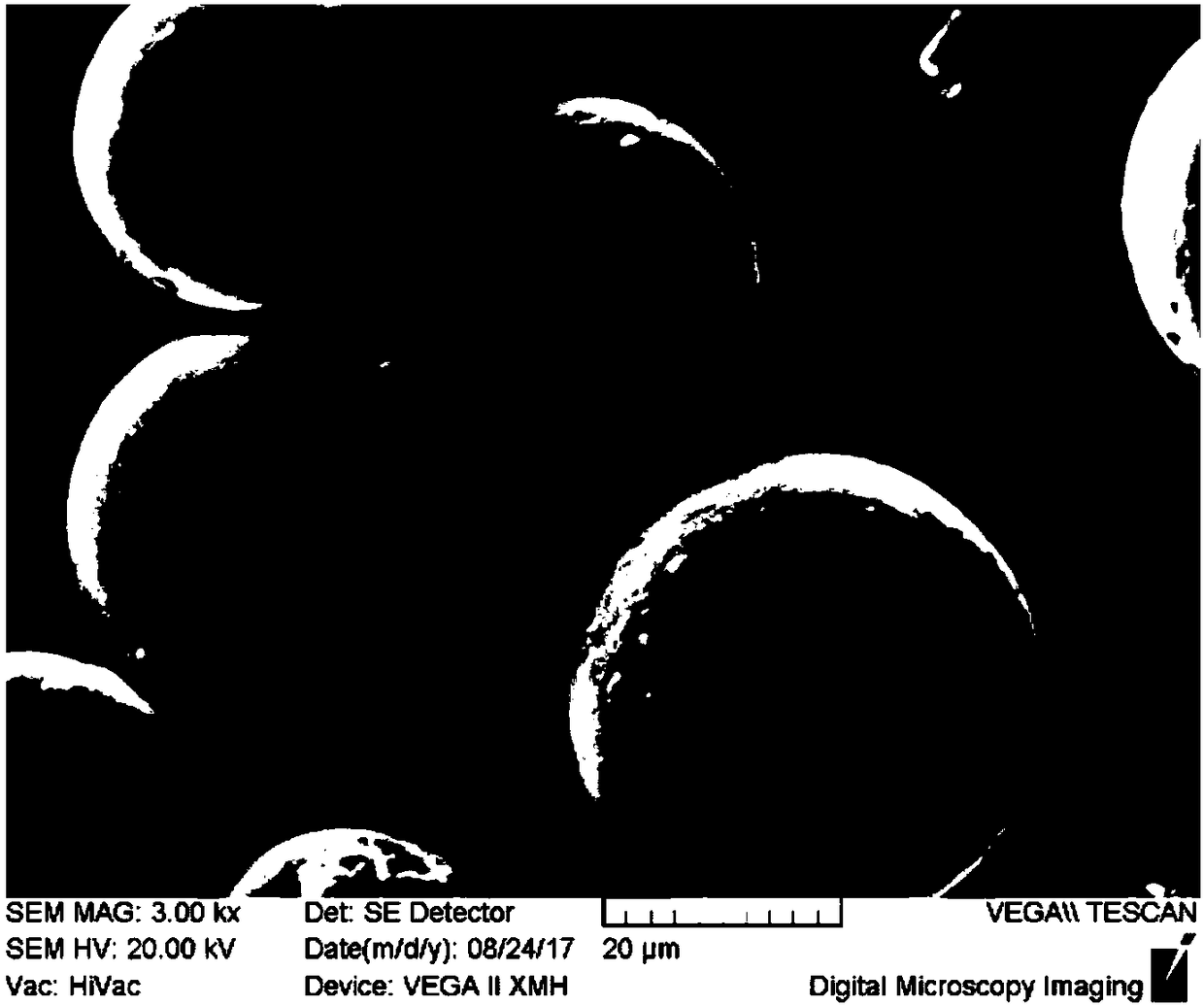

[0045] use figure 1 The radio frequency plasma powder production equipment shown produces spherical titanium nitride powder. The amplitude of the feeding device of the radio frequency plasma powder production equipment is set at 20%, the operating voltage is 10.5KV, and the power is 32kW. The "edge gas" (that is, the inlet of the protective gas) is fed with nitrogen, and the "intermediate gas" (that is, the inlet of the ionized gas) is fed with argon gas, and the flow rate of nitrogen gas is 3m 3 / h, argon gas flow rate is 3m 3 / h, where nitrogen is the reaction gas and argon is the ionizing gas. The feeding reaction was carried out for 5 minutes, and the materials were collected to prepare spherical titanium nitride powder. Its SEM picture is as follows image 3 As shown, its XRD pattern is shown in Figure 4 , Figure 4 The upper curve is the final product TiN prepared in Example 1, and the lower curve is TiN powder containing Ti. The spheroidization rate of this meth...

Embodiment 2

[0048] use figure 1 The radio frequency plasma powder production equipment shown produces spherical titanium nitride powder. The amplitude of the feeding device of the radio frequency plasma powder production equipment is set at 22%, the operating voltage is 11.5kV, and the power is 54kW. "Side gas" (that is, the protective gas inlet) is fed with nitrogen gas, and "middle gas" (that is, the ionized gas inlet) is first passed with argon gas to start the arc. After the arc is stable, close the argon gas and feed nitrogen gas, and adjust the "middle gas" flow rate to 3m 3 / h, the flow rate of "edge air" is 3m 3 / h, feeding reaction 5min receiving, the measured titanium nitride powder quality is 27g. Its SEM image and image 3 Similarly, its XRD pattern is similar to Figure 4 The above curve is similar. This method achieves a spheroidization rate of 92% and a nitriding rate of 86%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com