High-pressure hydrothermal and circulating fluidized bed pyrolysis-assisted rapid harmless sludge treatment process

A circulating fluidized bed, harmless treatment technology, applied in the field of solid waste resource utilization, can solve the problems of high energy consumption and high energy consumption of pyrolysis, and achieve low energy consumption, comprehensive resource treatment and disposal, and low equipment requirements. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Place 1500g of sludge produced by Beijing Qinghe Sewage Treatment Plant with a moisture content of 80% in a hydrothermal reactor, add 2% Ca(OH) 2 After sealing, nitrogen gas is introduced to ensure the inert atmosphere in the kettle, hydrothermal treatment is carried out at 180°C and autogenous pressure 1.8MPa for 60min, and stirring at 150rpm ensures uniform heat distribution;

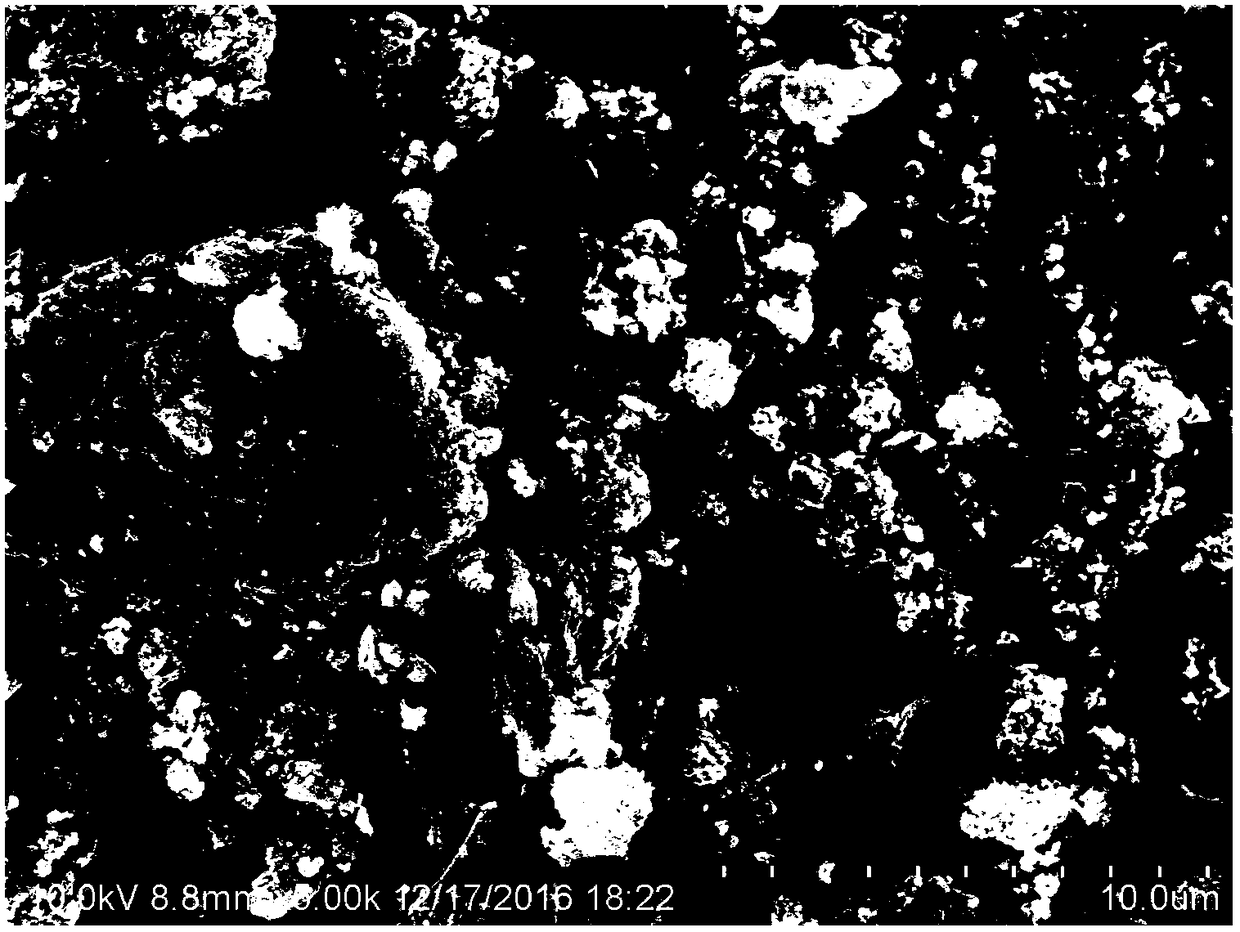

[0027] (2) The mixed hydrothermal product obtained in step (1) is mechanically dehydrated and solid-liquid separated, and the moisture content of the solid phase part is 52%. The solid phase product is also called hydrothermal charcoal and dried in an oven at 80 ° C. After drying, The solid sample was crushed to 50-150 mesh with a pulverizer, and the contents of K and Na in the hydrothermal charcoal were reduced by 4% and 30% respectively compared with the original sludge;

[0028] (3) Put the hydrothermal charcoal particles in step (2) in a fluidized bed screw feeder, and carry out pyrolys...

Embodiment 2

[0030] (1) Put 1500g of Qinghe sludge with a moisture content of 80% into a hydrothermal reactor and add 5% Ca(OH) 2 Seal it, feed nitrogen to ensure the inert atmosphere in the kettle, hydrothermally treat at 200°C, self-generated pressure 2.2MPa for 60min, stir at 120rpm to ensure uniform heat distribution;

[0031] (2) The mixed hydrothermal product obtained in step (1) is mechanically dehydrated and solid-liquid separated, and the moisture content of the solid phase part is 42%, and the solid phase product is dried in an oven at 80 ° C, and the dried solid sample is crushed with a pulverizer Grinding to 50-150 mesh, compared with the original sludge, the content of K and Na in the hydrothermal charcoal is reduced by 6% and 33% respectively;

[0032] (3) Place the hydrothermal charcoal particles in step (2) in a fluidized bed screw feeder, and carry out pyrolysis reaction at 500°C, the feed rate is 10g / min, the nitrogen flow rate is 2L / min, and the pyrolysis residue Into t...

Embodiment 3

[0034] (1) Put 1500g of Shandong sludge with a moisture content of 82% into a hydrothermal reactor and add 5% Ca(OH) 2 Seal it, feed nitrogen to ensure the inert atmosphere in the kettle, hydrothermally treat at 220°C, self-generated pressure 2.4MPa for 30min, stir at 150rpm to ensure uniform heat distribution;

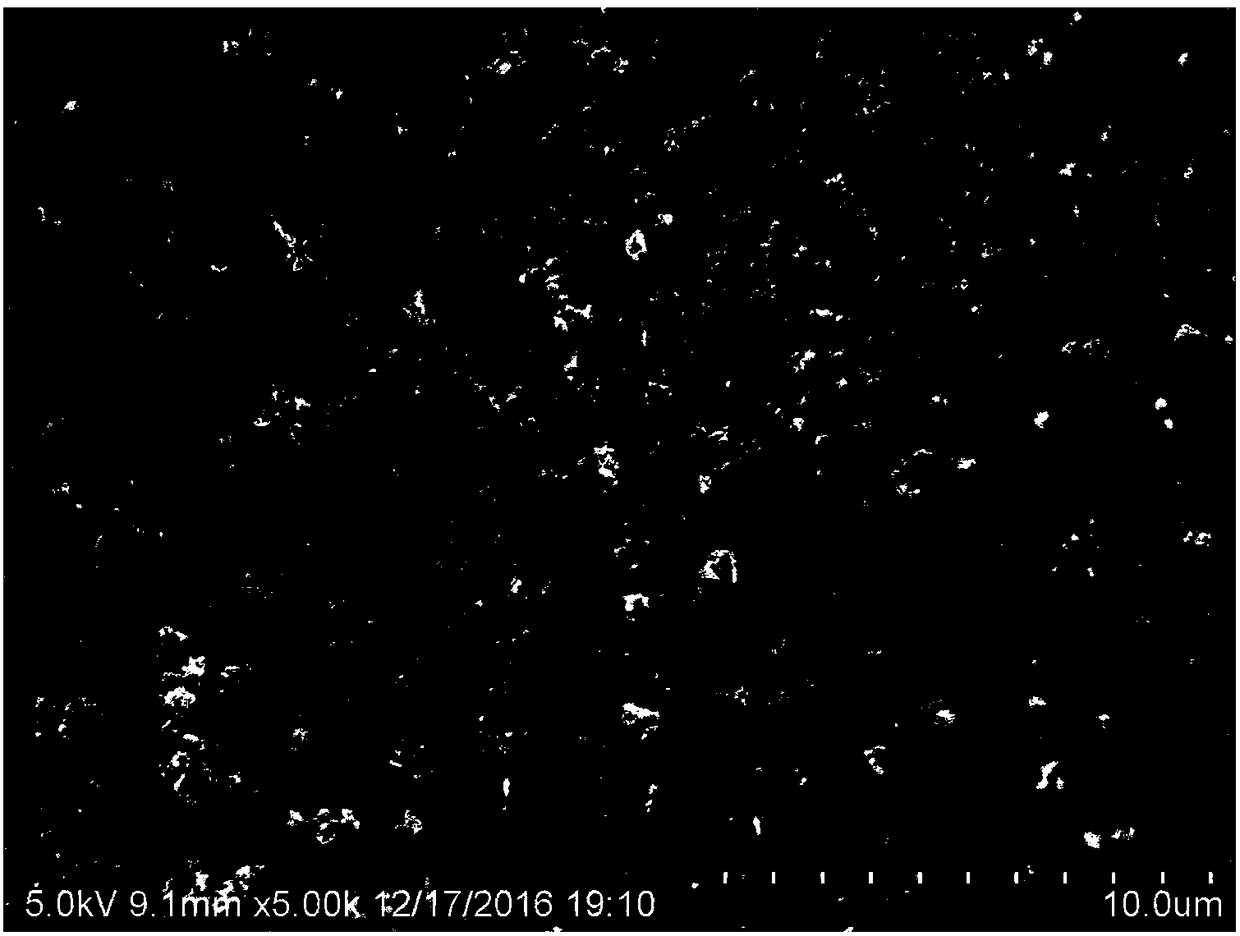

[0035] (2) mechanically dehydrating the mixed hydrothermal product obtained in step (1), separating solid and liquid, the moisture content of the solid phase part is 44%, drying the solid phase product at 80°C, and pulverizing it to 50-150 mesh;

[0036](3) Put the hydrothermal charcoal particles in step (2) in the fluidized bed screw feeder, and carry out the pyrolysis reaction at 600°C, the feed rate is 20g / min, the nitrogen flow rate is 3L / min, and the heating rate is At 20°C / min, pyrolytic charcoal enters the collector at the bottom of the fluidized bed, and the tar produced is cooled and collected. The pyrolytic carbon yield was 68%, and the tar yield was 8.5%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com