Preparation method of vinyl acetate-ethylene copolymerization emulsion

A technology of ethylene copolymer emulsion and vinyl acetate, applied in the direction of monocarboxylate copolymer adhesive, adhesive type, etc., can solve the problems such as easy generation of sediment in emulsion, unfavorable continuous operation of equipment, decrease in solid content of emulsion, etc. To achieve the effect of convenient industrialization, excellent dilution stability, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

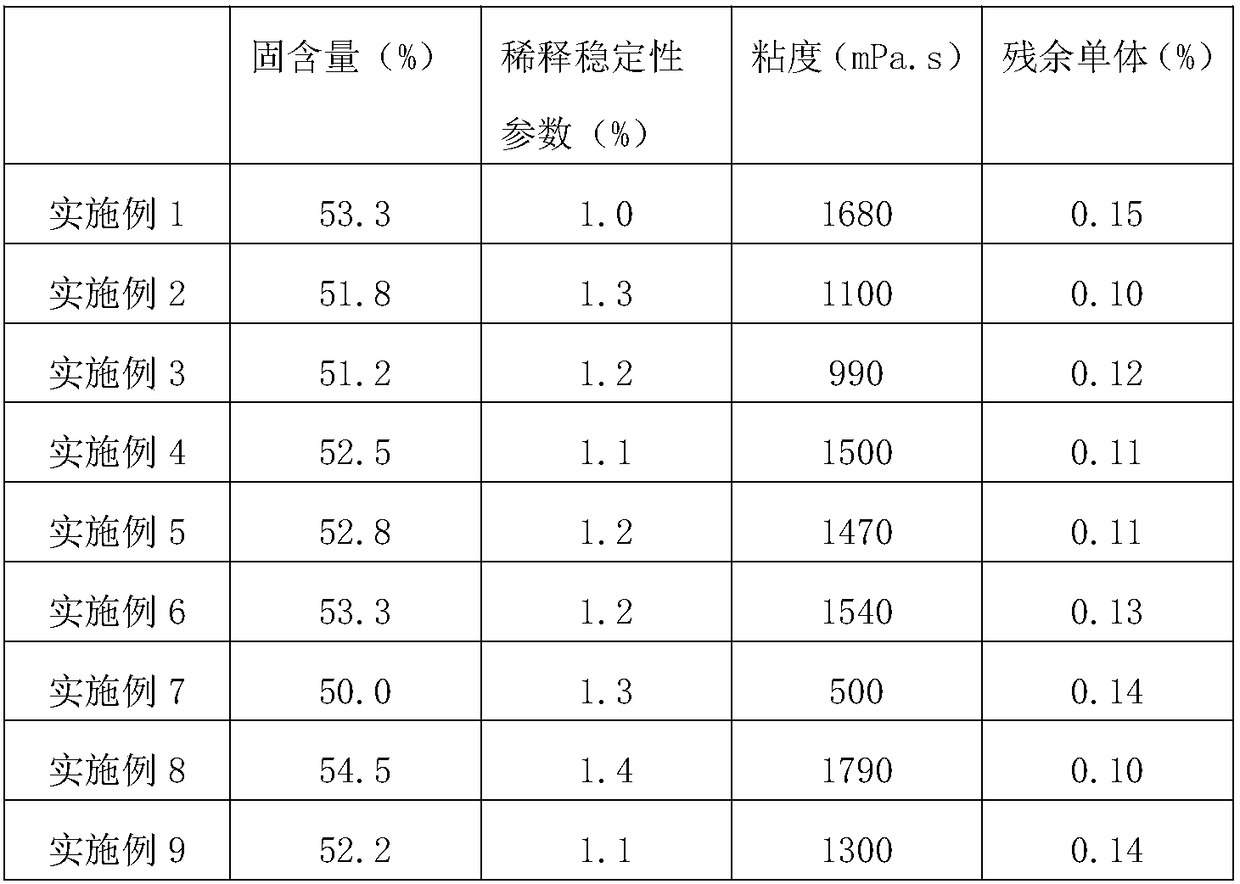

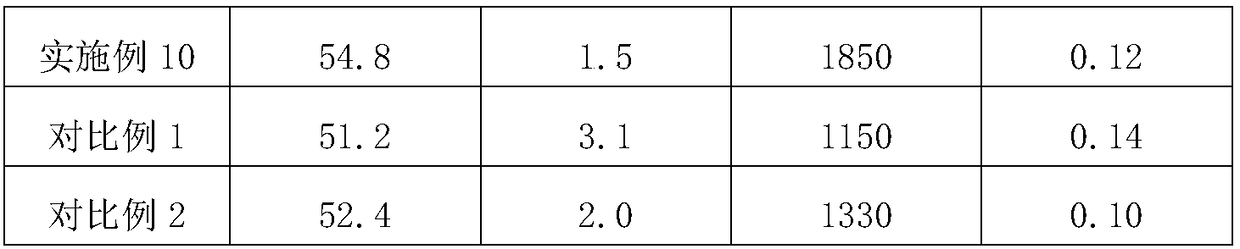

Examples

Embodiment 1

[0027] Add 35 parts of water into the reactor, then add 3 parts of PVA1788 and 3 parts of PVA1799 to dissolve, then add 25 parts of vinyl acetate and 10 parts of ethylene and stir evenly. When the temperature inside the reactor reached 60° C., 0.3 parts of zinc formaldehyde sulfoxylate and 0.3 parts of hydrogen peroxide were added. After 25 minutes, control the temperature of the reaction system to 80°C, add 25 parts of vinyl acetate, 6 parts of ethylene, 1 part of PVA0588, 0.1 part of alkylphenol polyoxyethylene ether ammonium sulfate, 0.1 part of zinc formaldehyde sulfoxylate, and 0.2 parts of hydrogen peroxide And 15 parts of water, control the dropwise addition within 60min. Degassing, cooling, filtering, discharging.

Embodiment 2

[0029] Add 30 parts of water into the reactor, then add 1 part of PVA2488, 2 parts of PVA1799 to dissolve, then add 20 parts of vinyl acetate and 10 parts of ethylene and stir evenly. When the temperature in the reactor reached 60° C., 0.1 parts of sodium formaldehyde sulfoxylate and 0.2 parts of hydrogen peroxide were added. After 25 minutes, control the temperature of the reaction system to 80°C, add 20 parts of vinyl acetate, 6 parts of ethylene, 1 part of PVA1088, 0.01 part of ammonium salt of alkylphenol polyoxyethylene ether sulfonate, 0.1 part of sodium formaldehyde sulfoxylate, and 0.2 parts of peroxide Hydrogen and 10 parts of water were added dropwise within 120 minutes under control. Degassing, cooling, filtering, discharging.

Embodiment 3

[0031] Add 32 parts of water into the reactor, then add 1.5 parts of PVA1788 and 1.5 parts of PVA1799 to dissolve, then add 20 parts of vinyl acetate and 7 parts of ethylene and stir evenly. When the temperature inside the reactor reached 50°C, 0.1 part of tartaric acid and 0.1 part of t-butyl hydroperoxide were added. After 30 minutes, control the temperature of the reaction system to 85°C, add 20 parts of vinyl acetate, 5 parts of ethylene, 1 part of PVA0588, 0.1 part of ammonium salt of alkylphenol polyoxyethylene ether sulfonate, 0.1 part of tartaric acid, and 0.1 part of tert-butyl peroxide Hydrogen and 10 parts of deionized water were added dropwise in about 70 minutes. Degassing, cooling, filtering, discharging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com