A super duplex stainless steel and its alloy composition optimization design method

A duplex stainless steel and alloy composition technology, applied in the field of duplex stainless steel, can solve the problems of steel stress corrosion, reduced service life, and deterioration of high temperature oxidation resistance of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The preparation of embodiment 1 super super duplex stainless steel

[0058] A 100kg pressurized induction furnace (80kg charge) was used to smelt 9 batches of steel. The chemical composition is shown in Table 1. Steels 1 to 7# are the super duplex stainless steel of the present invention, and the comparison examples are super duplex stainless steel S32750 and super duplex stainless steel S32707 respectively.

[0059] The method for preparation can adopt following steps:

[0060] (1), smelting and casting a slab, the composition of the slab is proportioned as shown in Table 1 by weight percentage, and the rest are Fe and unavoidable impurities;

[0061] (2), hot forging and hot rolling are carried out to described billet, and the thickness of forging plate is 30mm, and the thickness of rolling plate is 10mm, and wherein hot forging and hot rolling process are 1200±10 ℃, heat preservation 2h;

[0062] (3), the hot-rolled steel plate obtained in step (2) is subjected to ...

Embodiment 2

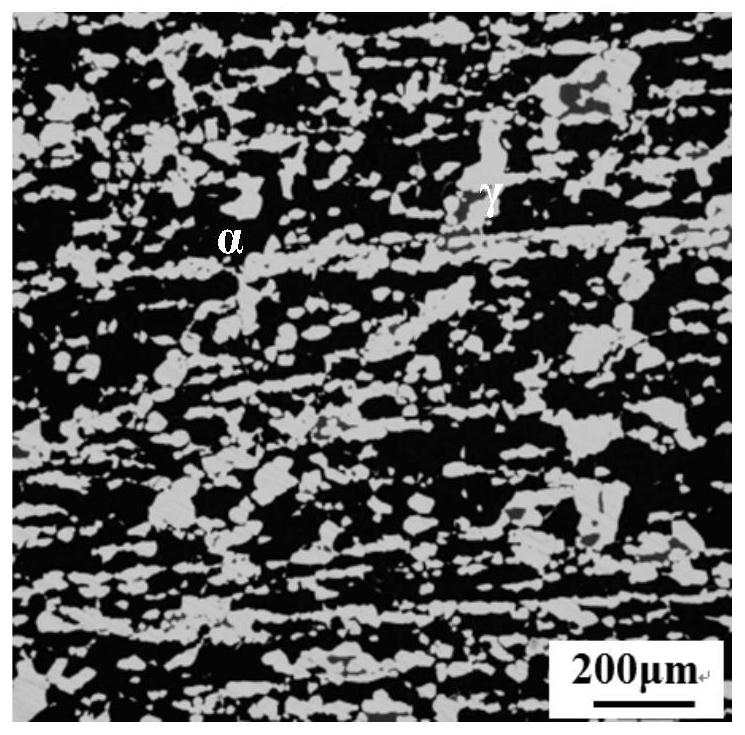

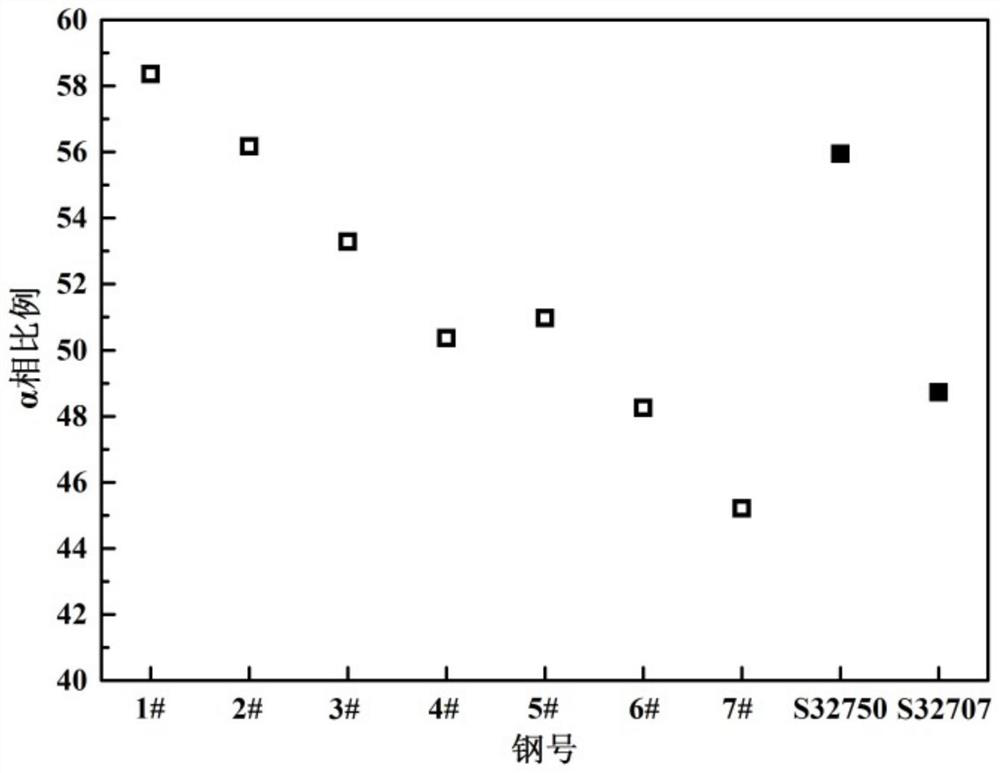

[0067] The structure stability of embodiment 2 special super duplex stainless steel

[0068] Cut some 10 * 10mm metallographic samples prepared in embodiment 1, observe the metallographic structure (such as figure 1 Shown the microstructure appearance of 4# steel) and count the super super duplex stainless steel of the present invention and the ferrite ratio after the comparative example solid solution treatment, the results are as follows figure 2 shown. It can be seen that the ferrite content of the ultra-super duplex stainless steel of the present invention and the comparative example are both between 40% and 60%, which meet the requirements of the invention. In addition, the phase ratio of 4# steel and 5# steel basically reaches 1:1, and both are better than the two comparative examples, indicating that the ultra-super duplex stainless steel of the present invention is easier to control the phase ratio of ferrite and austenite. At the same time, the solution-treated sam...

Embodiment 3

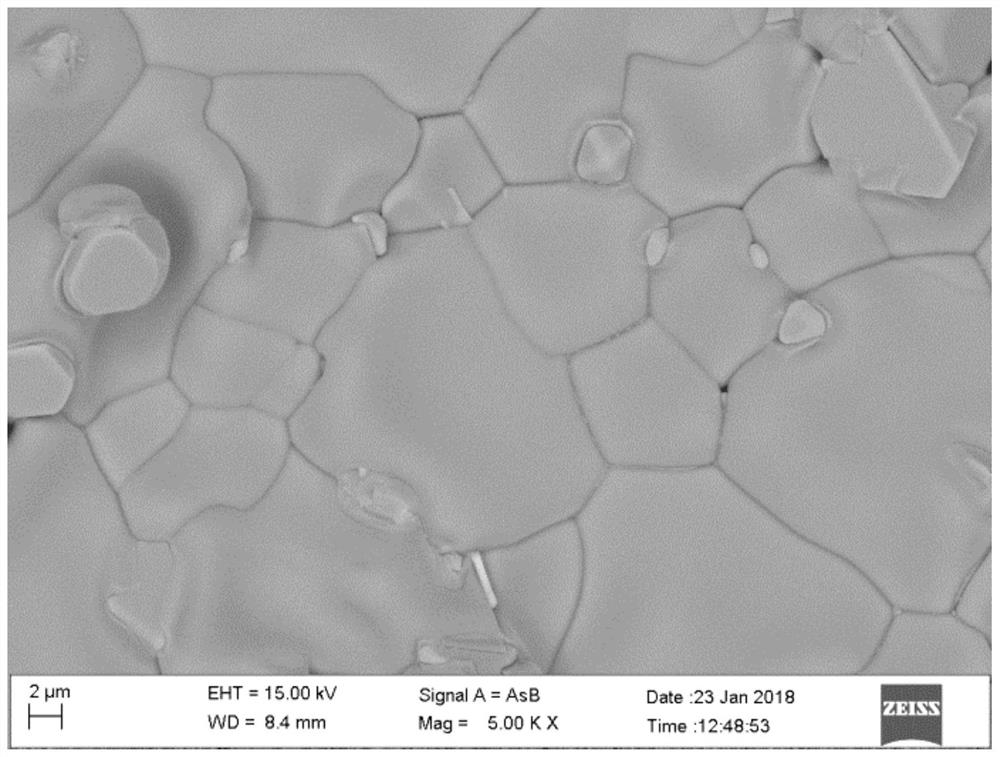

[0071] Example 3 The high temperature oxidation resistance of super super duplex stainless steel

[0072] Cut the present invention (1~7#) and comparative sample prepared in the embodiment 1 after some solid solution treatments, all surfaces are polished bright with 1200 mesh sandpaper, weigh the weight of the sample before oxidation (measuring accuracy is 0.1mg ), after being oxidized at 1200°C, cooled and weighed, and calculated the oxidation gain per unit surface area, the results are shown in Table 3, and the compactness and integrity of the oxide layer surface after oxidation were observed, as shown in image 3 and Figure 4 Shown are the SEM microstructures of the surface of the oxide layer after oxidation of 1# steel and S32707, respectively.

[0073] Table 3 The weight gain per unit area (mg / cm2) of the present invention and comparative examples after oxidation at 1200°C 2 )

[0074] time / t 1# 2# 3# 4# 5# 6# 7# S32750 S32707 5h 192.4 176.9 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com