Method for processing quartz resonator wafer

A technology of quartz resonators and processing methods, applied in piezoelectric/electrostrictive/magnetostrictive devices, impedance networks, electrical components, etc. Too consistent, the spread of the quartz wafer is not very good, etc., to achieve the effect of good parallelism, guaranteed strength, and good parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

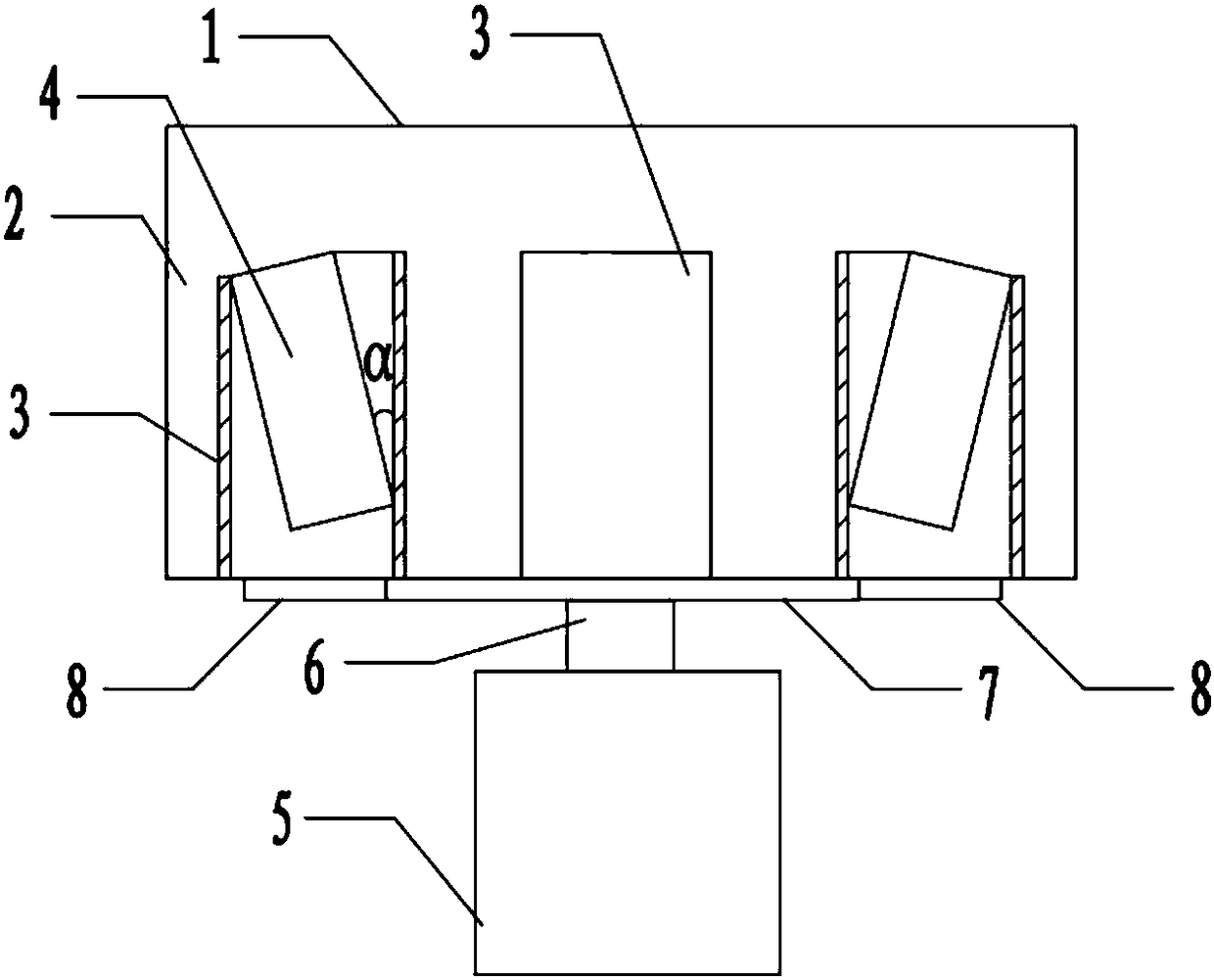

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples serve to illustrate the invention.

[0040] First, prepare the corrosion solution, the preparation steps of the corrosion solution are as follows:

[0041] a. Prepare ammonium fluoride solution: take container A and mix according to the weight ratio of ammonium fluoride and deionized water 1:1.35, and stir evenly;

[0042] b. Prepare hydrofluoric acid solution: Take container B and add deionized water first, then add hydrofluoric acid, the weight ratio of deionized water and hydrofluoric acid is 1:0.27, and then the ammonium fluoride solution and the solution in container B are in volume ratio 1:2 mix;

[0043] c. Preparation of surface stripping agent: perfluorooctane sulfonate ammonium: isopropanol: deionized water according to the weight ratio of 1:0.7:2 to prepare the surface st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com