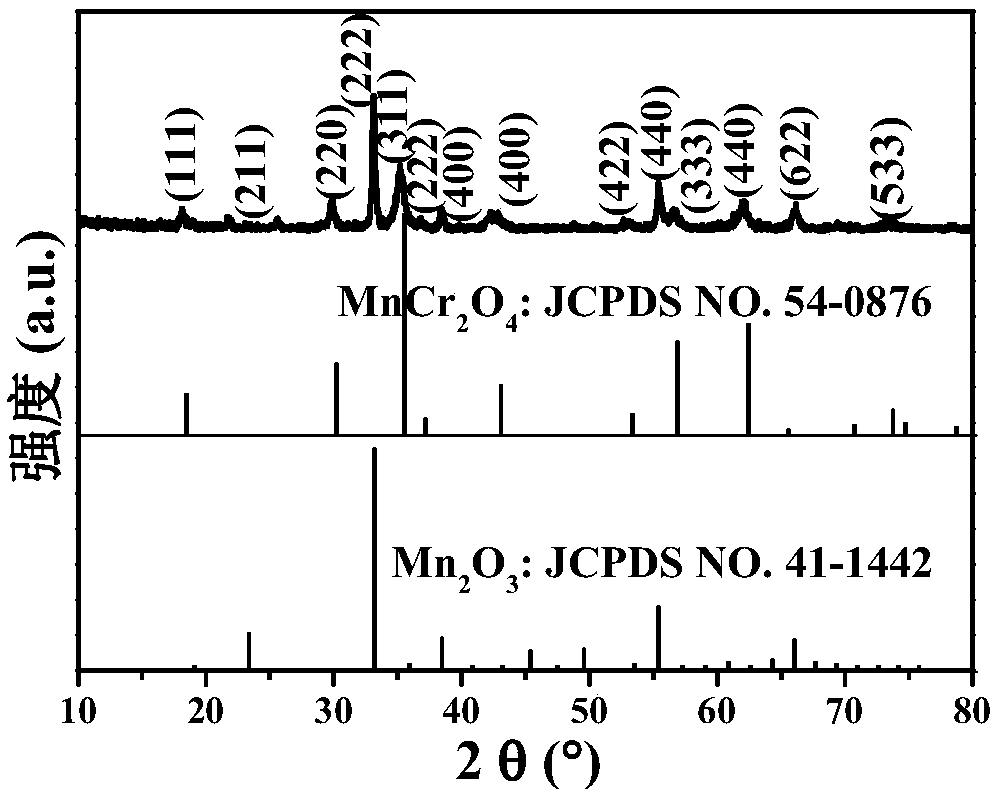

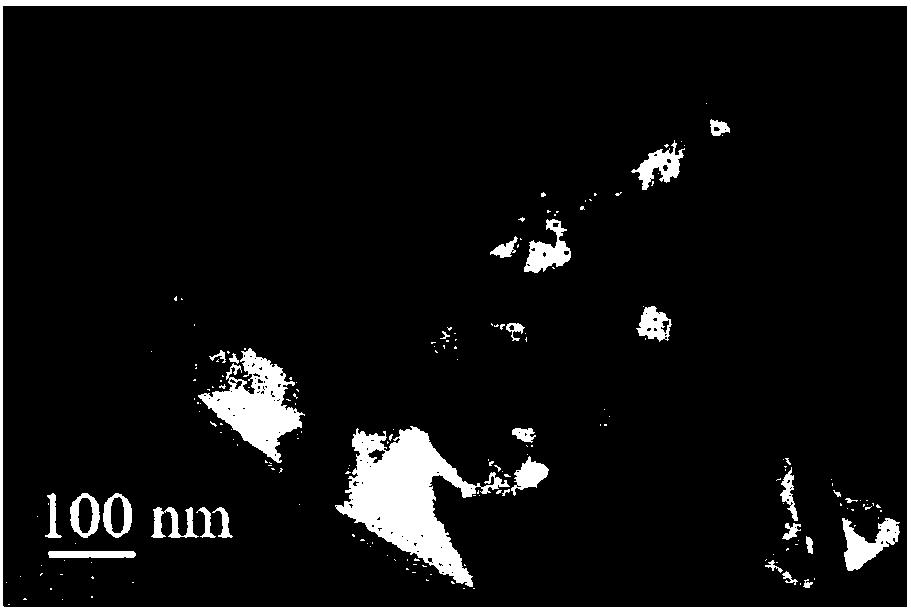

Preparation method and application of manganese-chromium binary metal oxide energy storage material

A technology of energy storage materials and binary metals, applied in the field of new materials, can solve problems such as poor rate performance and poor cycle stability, and achieve the effects of good rate performance, low environmental pollution, and inhibition of single-phase grain agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing a manganese-chromium binary metal oxide energy storage material, comprising the steps of:

[0027] The mixed solution of sodium hydroxide and sodium carbonate is added dropwise to the mixed solution of manganese chloride and chromium chloride by co-precipitation method, while stirring while adding dropwise, the concentration of manganese chloride solution in the mixed solution is 0.4mol / L, chlorine The concentration of chromium chloride solution is 0.2mol / L, the concentration of sodium hydroxide is 0.1mol / L, the concentration of sodium carbonate is 0.05mol / L, the molar ratio of manganese chloride and chromium chloride is 2:1, dropwise to Mix the solution to alkaline, stir for 0.5h after the dropwise addition; then age at 80°C for 12h; wash the precipitate, dry it and crush it; then raise the temperature at a rate of 5°C / min to 800°C, and maintain at 800°C for 120min. After grinding and sieving, a nano-flaky manganese-chromium binary metal oxide c...

Embodiment 2

[0029] The mixed solution of sodium hydroxide and sodium carbonate is added dropwise to the mixed solution of manganese chloride and chromium chloride by co-precipitation method, while stirring while adding dropwise, the concentration of manganese chloride solution in the mixed solution is 0.4mol / L, chlorine The concentration of chromium chloride solution is 0.1mol / L, the concentration of sodium hydroxide is 0.1mol / L, the concentration of sodium carbonate is 0.05mol / L, the molar ratio of manganese chloride and chromium chloride is 4:1, dropwise to Mix the solution to alkaline, stir for 0.5h after the dropwise addition; then age at 80°C for 12h; wash the precipitate, dry it and crush it; then raise the temperature at a rate of 5°C / min to 800°C, and maintain at 800°C for 120min. After grinding and sieving, a nano-manganese-chromium binary metal oxide composite material is obtained, which is the energy storage material.

Embodiment 3

[0031] The mixed solution of sodium hydroxide and sodium carbonate is added dropwise to the mixed solution of manganese chloride and chromium chloride by co-precipitation method, while stirring while adding dropwise, the concentration of manganese chloride solution in the mixed solution is 0.2mol / L, chlorine The concentration of chromium chloride solution is 0.2mol / L, the concentration of sodium hydroxide is 0.1mol / L, the concentration of sodium carbonate is 0.05mol / L, the molar ratio of manganese chloride and chromium chloride is 1:1, dropwise to Mix the solution to alkaline, stir for 0.5h after the dropwise addition; then age at 80°C for 12h; wash the precipitate, dry it and crush it; then raise the temperature at a rate of 5°C / min to 800°C, and maintain at 800°C for 120min. After grinding and sieving, a nano-manganese-chromium binary metal oxide composite material is obtained, which is the energy storage material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com