Preparation method of nickel-based alloy electrolysis hydrogen evolution cathode porous material

A porous material, nickel-based alloy technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of small specific surface area of hydrogen evolution electrode, poor resistance to power failure and short circuit, low hydrogen evolution overpotential, etc. Inexpensive, low hydrogen evolution overpotential effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

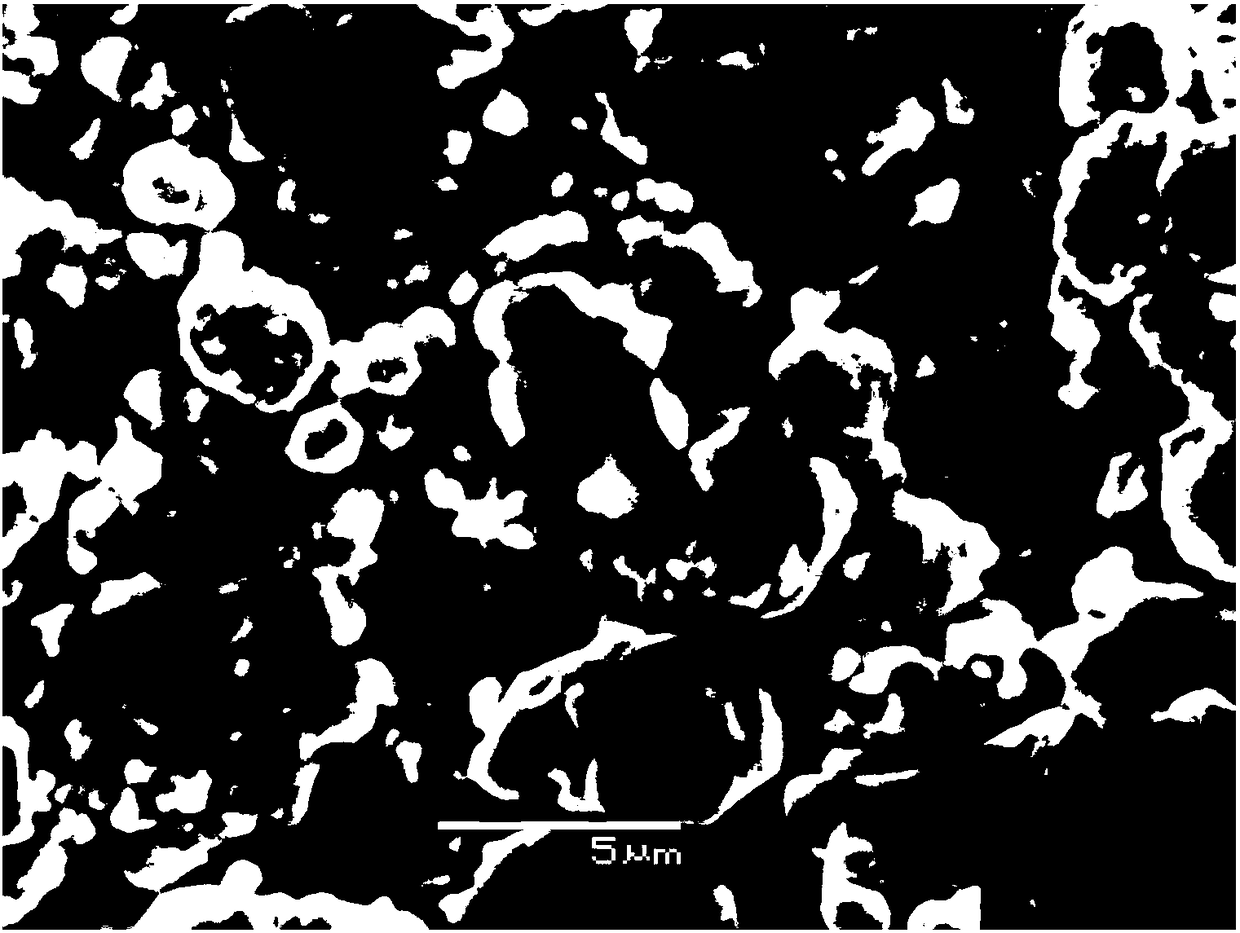

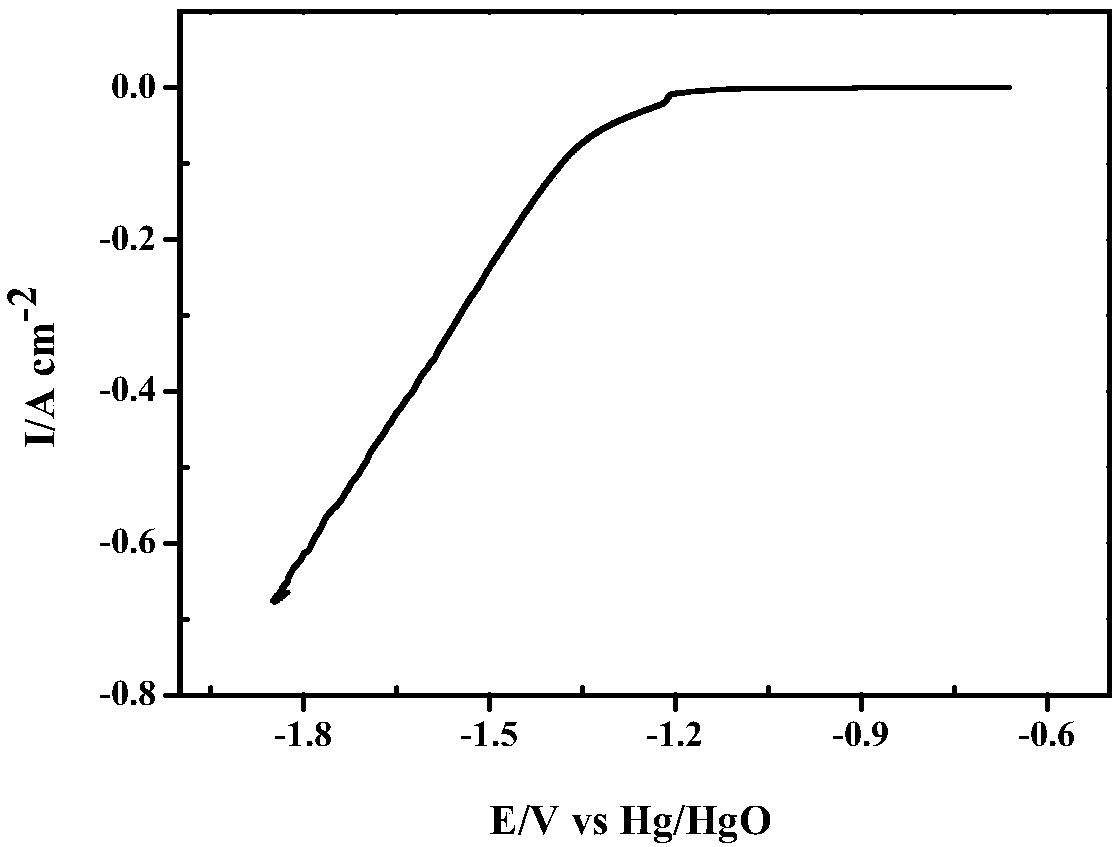

[0024] Ni, W, Al, LaNi 5 The four kinds of powders are prepared according to the mass percentage, wherein the W content is 15%, the powder particle size is 3μm; the Al content is 10%, the powder particle size is 5μm; the LaNi5 content is 7%, the powder particle size is 20μm; the balance is powder Ni powder with a particle size of 8 μm. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 8 hours, then add stearic acid of 2% of the total powder mass, and then dry for 7 hours, and then cold press it under a cold press at a pressure of 100 MPa, and the holding time is about 40s ; Place the pressed sample in a vacuum furnace at a vacuum of 1x10 -2 In the case of Pa, maintain a heating rate of 10°C / min from room temperature to 110°C and keep it for 30 minutes; then raise the temperature to 270°C at a heating rate of 5°C / min and keep it for 60 minutes; then raise the temperature at a heating rate of 3°C / min to 450°C and keep it at this temperature fo...

Embodiment 2

[0028] Ni, W, Al, LaNi 5The four kinds of powders are prepared according to the mass percentage, wherein the W content is 28%, the powder particle size is 5 μm; the Al content is 5%, the powder particle size is 8 μm; the LaNi5 content is 3%, the powder particle size is 40 μm; the balance is powder Ni powder with a particle size of 5 μm. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 10 hours, then add 1% stearic acid of the total powder mass, and then dry for 12 hours, and cold press it under a cold press at a pressure of 50 MPa, and the holding time is about 100s ; Place the pressed sample in a vacuum furnace at a vacuum of 4x10 -3 In the case of Pa, maintain a heating rate of 5°C / min from room temperature to 150°C and keep it for 20 minutes; then raise the temperature at a rate of 8°C / min to 400°C and keep it for 40 minutes; then raise the temperature at a rate of 5°C / min to 550°C and keep at this temperature for 40min; then raise the t...

Embodiment 3

[0031] Ni, W, Al, LaNi 5 The four kinds of powders are prepared according to the mass percentage, wherein the W content is 20%, the powder particle size is 8μm; the Al content is 13%, the powder particle size is 6μm; the LaNi5 content is 5%, the powder particle size is 50μm; the balance is powder Ni powder with a particle size of 6 μm. Put the prepared powder on a V-type powder mixer and mix it at a constant speed for 7 hours, then add 1.5% stearic acid of the total powder mass, and then dry it for 9 hours, and cold press it under a cold press at a pressure of 120 MPa, and the holding time is about 25s ; Place the pressed sample in a vacuum furnace at a vacuum of 5x10 -3 In the case of Pa, maintain a heating rate of 8°C / min, from room temperature to 120°C, and hold for 40 minutes; then raise the temperature to 300°C at a heating rate of 10°C / min, and hold for 50 minutes; then raise the temperature at a heating rate of 6°C / min to 600°C and keep it at this temperature for 30 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com