Calcium dihydrogen phosphate processing method and device

A technology of calcium dihydrogen phosphate and a processing method, applied in the field of phosphorus chemical industry, can solve the problems of poor operation stability of the product quality device of the dry powder direct granulation method, large amount of dust, easy agglomeration of products, etc., and achieves extended operation period and stable quality. , the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

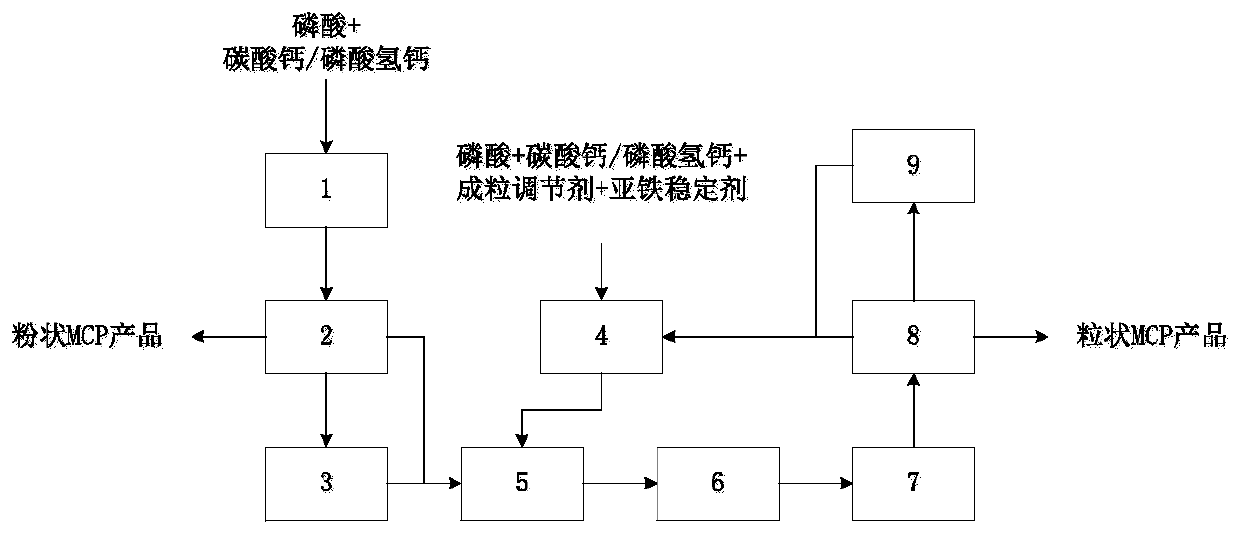

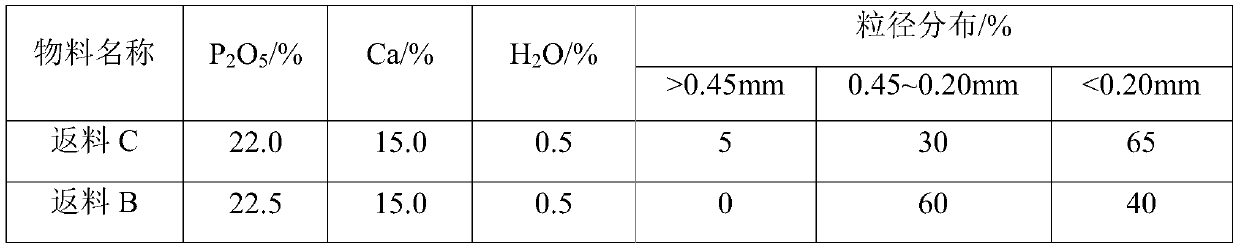

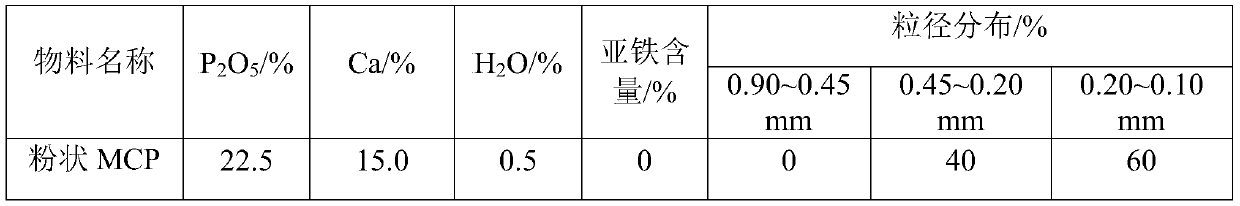

Embodiment 1

[0038] Use P 2 o 5 The calcium carbonate slurry with a concentration of 40% defluorinated phosphoric acid and a water content of 50% is prepared in the MCP reaction tank 1 to obtain the MCP slurry, which is atomized and dried in the spray drying tower 2 to obtain a powdery MCP product, and the dry tail gas is dedusted Dust material is obtained from dedusting in room 3, which is mixed with powdered MCP product at a dry basis mass ratio of 1:10 as return material B; calcium carbonate powder with a water content of 0.01% and P 2 o 5When the concentration is 40%, the dosage of defluorophosphoric acid is adjusted according to the Ca / P ratio of 0.60, and 0.1% of ferrous fumarate and ferrous glycinate, 0.1% of sodium metabisulfite are added, and the weight ratio of the returned material C is 1:3 on a dry basis Enter primary reactor 4, reactant temperature 60 ℃, residence time 10s, obtain material D moisture content 13%, material D and return material B enter secondary reactor 5 acc...

Embodiment 2

[0045] Use P 2 o 5 The concentration is 45% defluorinated phosphoric acid and calcium hydrogen phosphate slurry with a water content of 40%. The MCP slurry is prepared in the MCP reaction tank 1, and the powdery MCP product is obtained after atomization and drying in the spray drying tower 2. The dry tail gas is passed through Dust material obtained by dedusting in dust removal room 3 is mixed with powdered MCP product at a ratio of 1:5 as return material B; calcium hydrogen phosphate powder with a water content of 3.0% and P 2 o 5 The concentration is 45%. The dosage of defluorinated phosphoric acid is adjusted according to the Ca / P ratio of 0.61. Add 0.5% ferrous carbonate and 0.5% sodium metabisulfite, and return material C to enter primary reactor 4 at a dry basis mass ratio of 1:2. , the temperature of the reactant is 70°C, the residence time is 15s, and the moisture content of the material D is 20%. The material D and the returned material B enter the secondary reactor...

Embodiment 3

[0051] Use P 2 o 5 The calcium bicarbonate slurry whose concentration is 45% defluorinated phosphoric acid and 40% water content is prepared in the MCP reaction tank 1 to obtain the MCP slurry, which is atomized and dried in the spray drying tower 2 to obtain a powdery MCP product, and the dry tail gas is passed through Dust removal room 3 obtains dust material, which is mixed with powdered MCP product at 1:1 as return material B; calcium bicarbonate powder with a water content of 1% and P 2 o 5 The concentration is 45%, the dosage of defluorophosphoric acid is adjusted according to the Ca / P ratio of 0.63, and 1.5% ferrous chloride and 1.0% sodium thiosulfate are added, and the mass ratio of the returned material C is 1:2 on a dry basis to enter the first stage Reactor 4, the temperature of the reactant is 70°C, and the residence time is 25s. The moisture content of the material D is 20%. Time 15s, obtain material E moisture content 7%, enter granulator 6 granulation, granu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com