Device and method for preparing mesocarbon microbeads from medium-temperature coal pitch

A technology of mesophase carbon microspheres and coal tar pitch, which is applied in the preparation/purification of carbon, etc., can solve the problems of high production cost, easy fusion of small balls, complicated process, etc., and achieve improved product performance level and surface smoothness , separation and clean effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

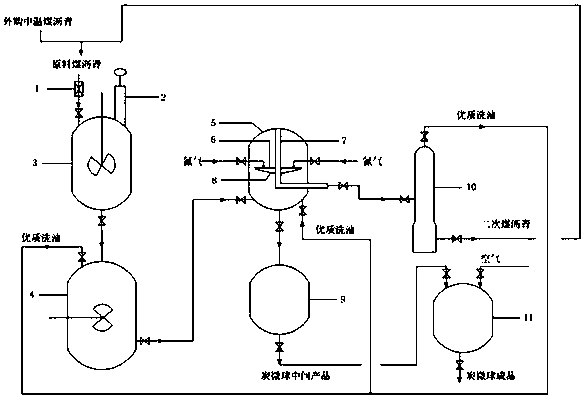

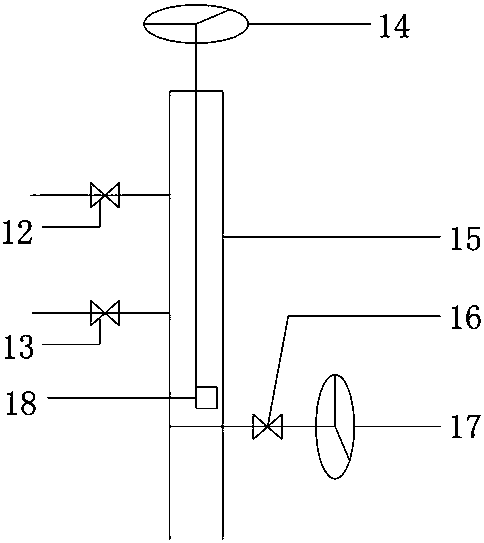

[0034] Such as figure 1 As shown, the device for preparing mesophase carbon microspheres from medium-temperature coal tar pitch of the present invention includes a reaction kettle 3, a washing kettle 4, a filter kettle 5, a drying kettle 9, an oxidation kettle 11 and a distillation tower 10. The upper part of the reaction kettle 3 is provided with a mass flow rate Meter 1 and sampler 2, the bottom of reaction kettle 3 is connected with the top of washing kettle 4 through pipelines, the lower part of washing kettle 4 is connected with the lower part of filter kettle 5 through pipelines, and a filter disc 8 is arranged in filter kettle 5, and there is a filter screen on filter disc 8 6. There are nitrogen inlet pipes on both sides of the middle of the filter kettle 5, which are separated by nitrogen pressure filtration. The filter kettle 5 is also equipped with an "L"-shaped hollow tube 7, and one end of the hollow tube 7 passes through the filter disc 8 and the filter screen 6 ...

Embodiment 2

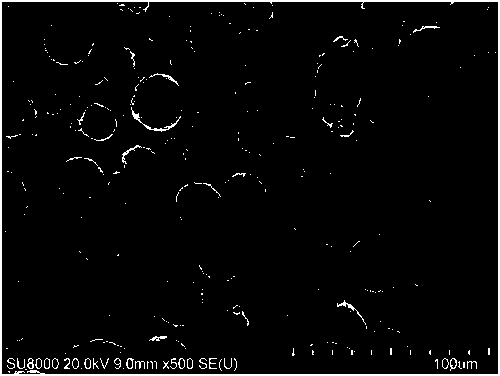

[0051] The method for preparing mesophase carbon microspheres from medium-temperature coal tar pitch is completed in the following steps:

[0052] a. Preparation of raw coal tar pitch: mix the secondary coal tar pitch after extracting the mesophase carbon microspheres with the purchased medium-temperature coal tar pitch in a mass ratio of 1:3 to obtain the raw coal tar pitch with a quinoline insoluble content of 4.6%;

[0053] b. Thermal polycondensation reaction: The raw material coal tar pitch is measured by the mass flow meter 1 and then added to the reactor 3 for thermal polycondensation reaction. After heating to 400°C, the particles of the mesophase carbon microspheres are sampled by the sampler 2 every 0.5 hours When the particle size reaches the target particle size, the reaction is stopped to obtain the mother liquor of carbon microspheres. The reaction parameters are as follows: Stirring rate: 85r / min, heating rate: 55°C / h, reaction temperature: 455°C, constant temper...

Embodiment 3

[0065] The method for preparing mesophase carbon microspheres from medium-temperature coal tar pitch is completed in the following steps:

[0066] a. Preparation of raw coal tar pitch: mix the secondary coal tar pitch after extracting mesophase carbon microspheres with the purchased medium-temperature coal tar pitch at a mass ratio of 1:5 to obtain the raw coal tar pitch with a content of quinoline insolubles of 6%;

[0067] b. Thermal polycondensation reaction: The raw material coal tar pitch is measured by the mass flow meter 1 and then added to the reactor 3 for thermal polycondensation reaction. After heating to 400°C, the particles of the mesophase carbon microspheres are sampled by the sampler 2 every 0.5 hours When the particle size reaches the target particle size, the reaction is stopped to obtain the mother liquid of carbon microspheres. The reaction parameters are as follows: stirring rate: 100r / min, heating rate: 60°C / h, reaction temperature: 460°C, constant tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tap density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com