Mesoporous petroleum-coke-based activated carbon and preparation method thereof

A technology of activated carbon and petroleum coke, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve the problems of low yield, difficult petroleum coke impregnation treatment, general final effect, etc., and achieve the effect of high proportion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] A preparation method of mesoporous petroleum coke-based activated carbon, comprising the following steps:

[0025] 1) Crushing, grinding and sieving petroleum coke raw materials to obtain petroleum coke powder;

[0026] 2) mixing the petroleum coke powder and the ionic liquid, fully impregnating, filtering, recycling and reusing the filtrate, washing the solid product with water to neutrality, and drying to obtain the pretreated petroleum coke powder;

[0027] 3) Mix the pretreated petroleum coke powder with an activator, place it in a closed furnace, fill it with protective gas, and activate it, and then wash, pickle, wash, and dry the activated product to obtain mesoporous petroleum coke Coke-based activated carbon.

[0028] Preferably, the petroleum coke raw material in step 1) is at least one of needle coke, sponge coke, spherical coke and pitch coke.

[0029] Preferably, the petroleum coke raw material in step 1) is uncalcined petroleum coke.

[0030] Preferably...

Embodiment 1

[0049] A preparation method of mesoporous petroleum coke-based activated carbon, comprising the following steps:

[0050] 1) Crushing, grinding and sieving the needle coke before calcining to obtain petroleum coke powder with a particle size of 75-150 μm;

[0051] 2) Mix petroleum coke powder and ionic liquid 1-butyl-3-methylimidazolium hydroxide according to the mass ratio of 1:1.5, impregnate at room temperature for 12 hours, filter, recover and recycle the filtrate, wash the solid product until neutral, Dry to obtain pretreated petroleum coke powder;

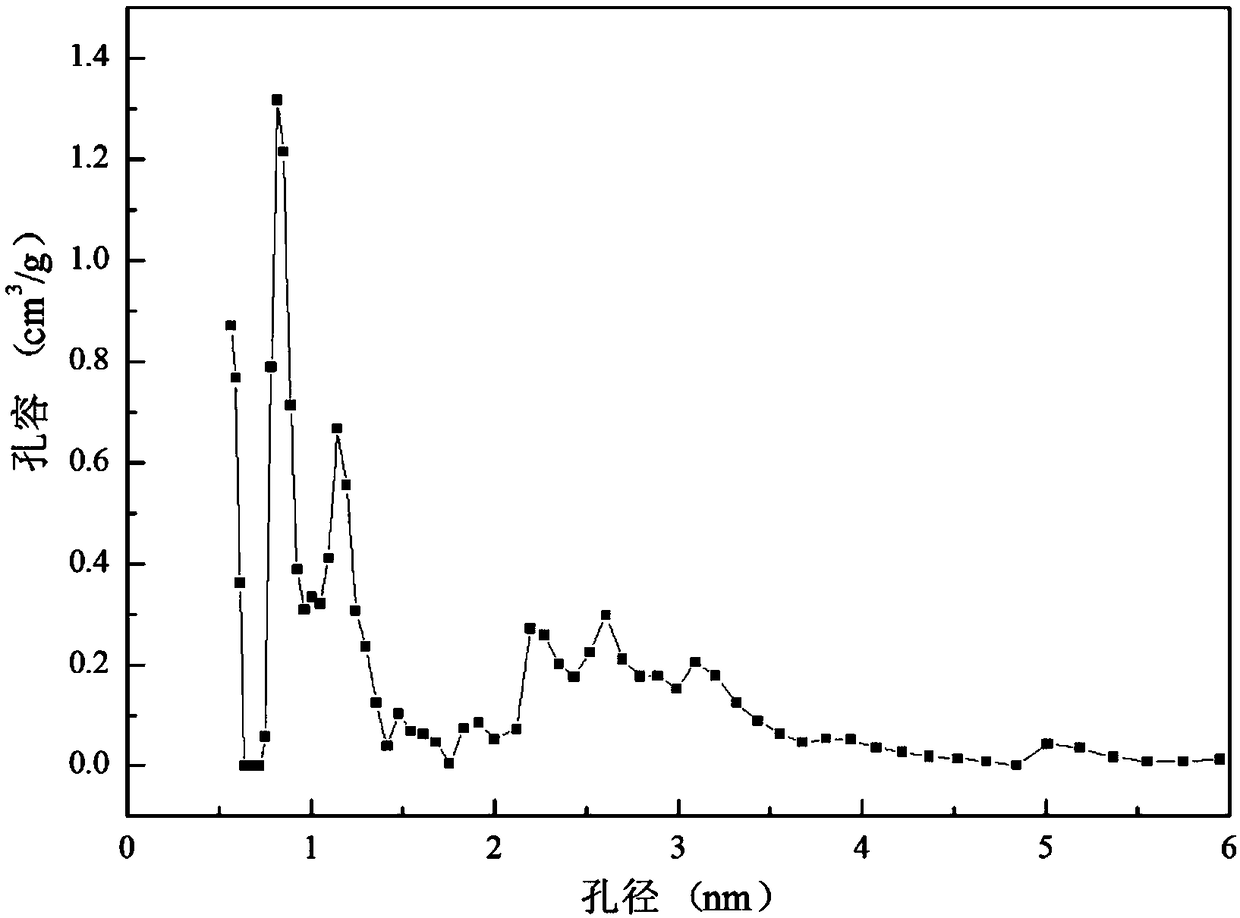

[0052] 3) Mix the pretreated petroleum coke powder and KOH at a mass ratio of 1:3, place in a tube furnace, fill with nitrogen, raise the temperature to 700°C at a heating rate of 10°C / min, activate at constant temperature for 2 hours, and then The activated product is washed with water, pickled, washed with water until neutral, and dried to obtain mesoporous petroleum coke-based activated carbon with a specific surface area...

Embodiment 2

[0054] A preparation method of mesoporous petroleum coke-based activated carbon, comprising the following steps:

[0055] 1) Crushing, grinding and sieving the sponge coke before calcining to obtain petroleum coke powder with a particle size of 75-150 μm;

[0056] 2) Mix petroleum coke powder and ionic liquid 1-ethyl-3-methylimidazolium hydroxide according to the mass ratio of 1:0.5, impregnate at room temperature for 12 hours, filter, recover and recycle the filtrate, wash the solid product with water until neutral, Dry to obtain pretreated petroleum coke powder;

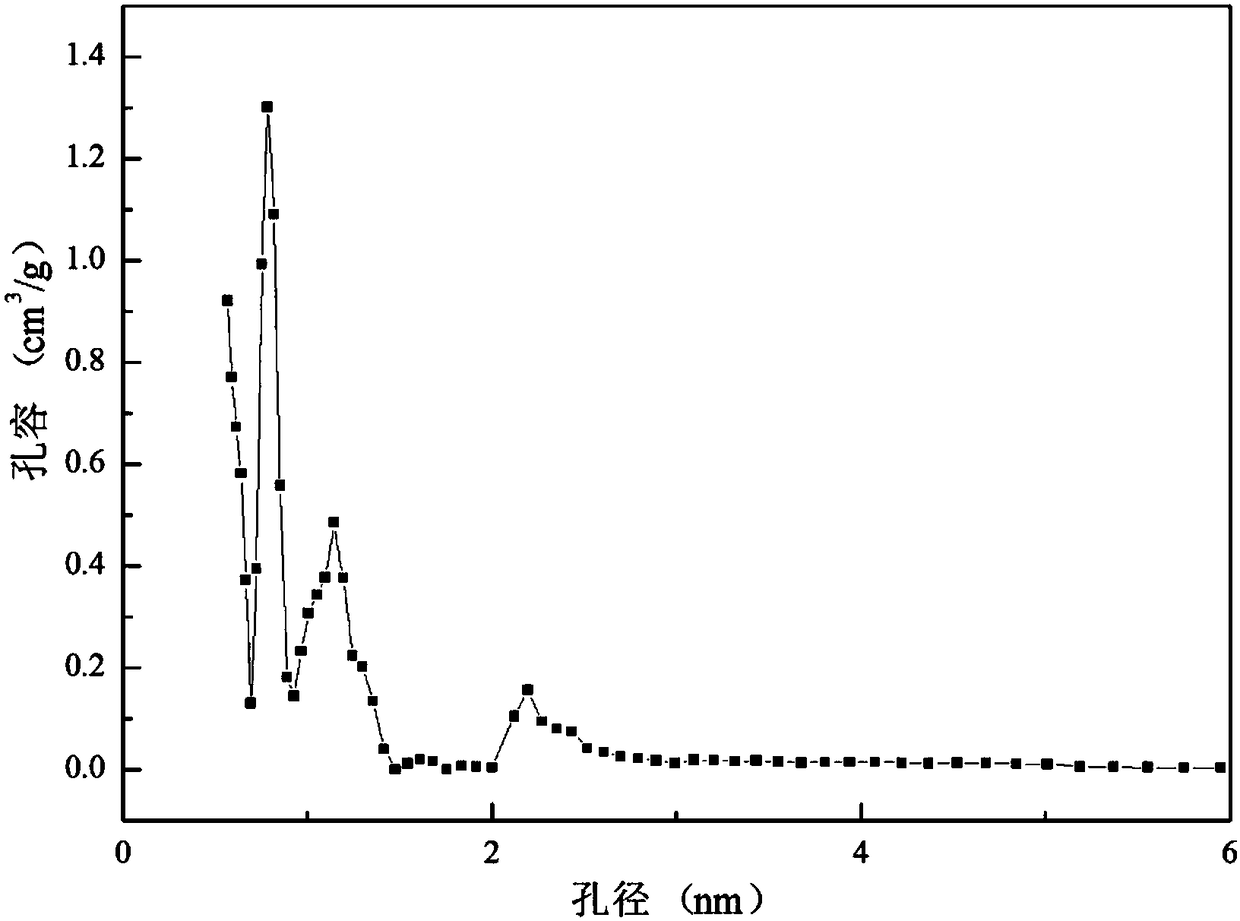

[0057] 3) Mix the pretreated petroleum coke powder and KOH according to the mass ratio of 1:2.5, place in a tube furnace, fill with nitrogen, raise the temperature to 650°C at a heating rate of 15°C / min, activate at constant temperature for 3 hours, and then The activated product is washed with water, pickled, washed with water until neutral, and dried to obtain mesoporous petroleum coke-based activated carbon wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com