Hydroxyl-terminated liquid rubber modified polyester polyol as well as preparation method and application thereof

A technology of liquid rubber and modified polyester, which is applied in the field of hydroxyl-terminated liquid rubber-modified polyester polyol and its preparation and application. It can solve the problems of peeling of polyurethane shoe soles, low primary hydroxyl content, and low primary hydroxyl. Achieve the effect of improving low temperature folding resistance, excellent low temperature resistance and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

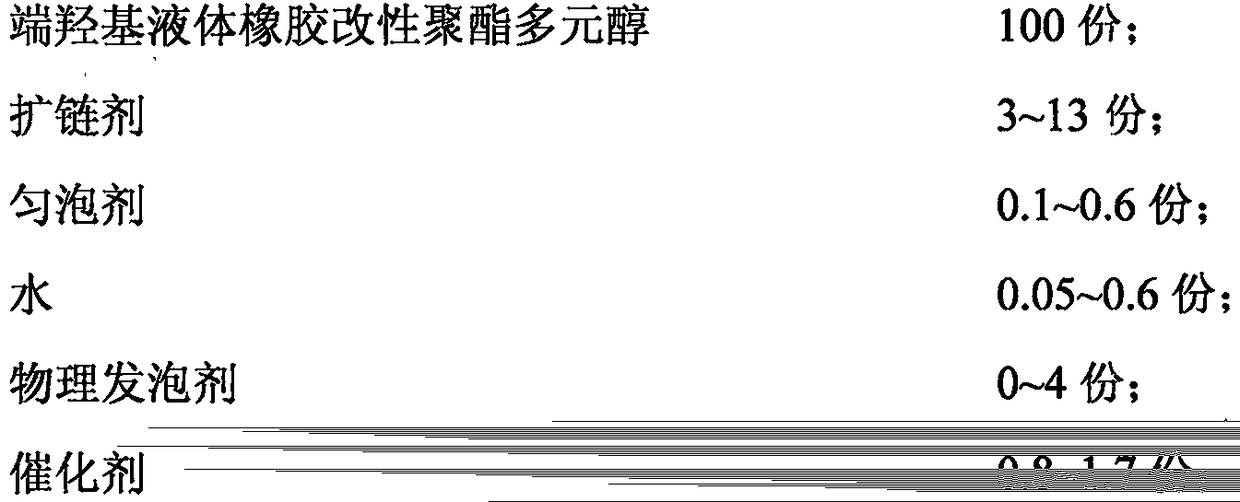

Method used

Image

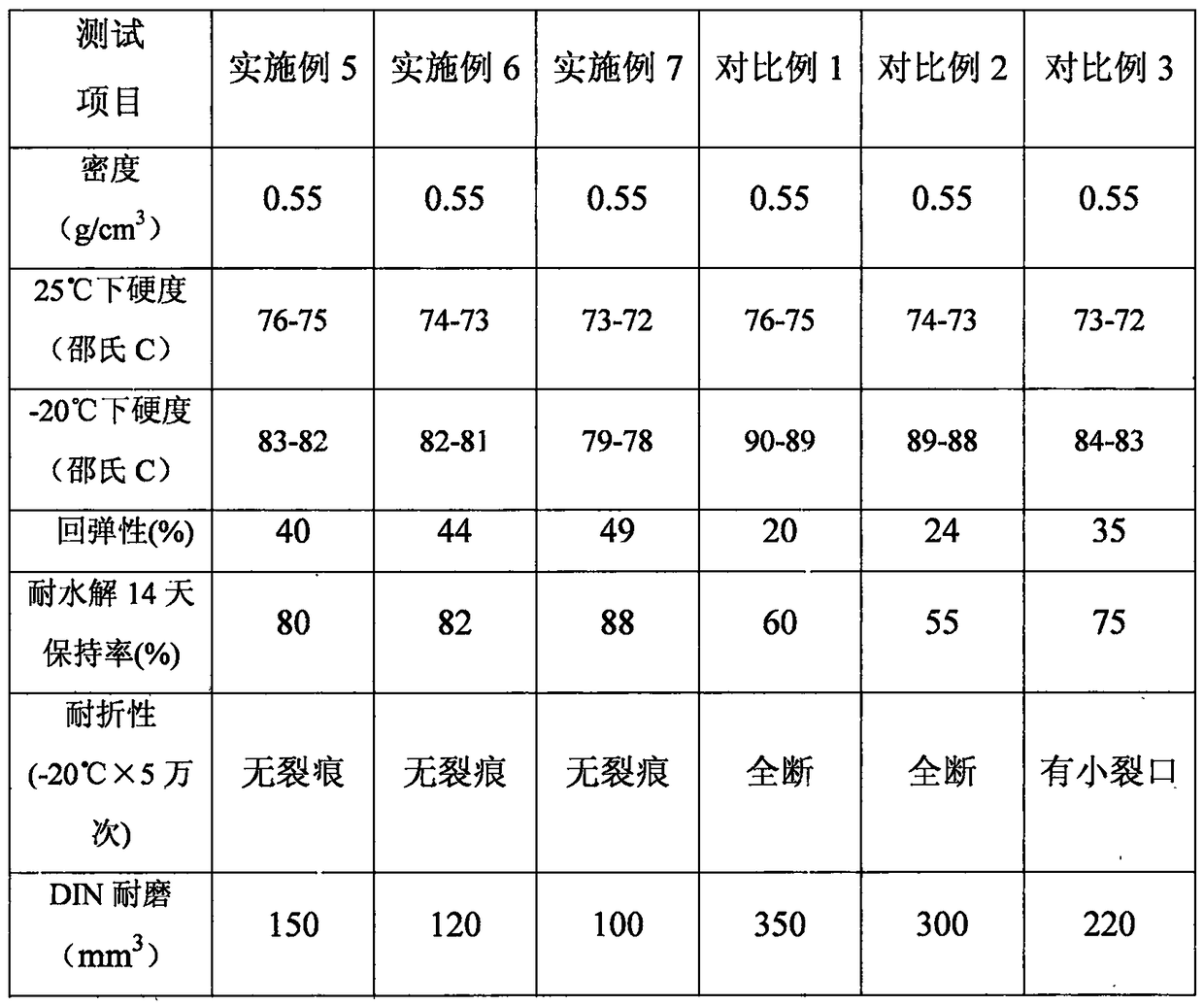

Examples

Embodiment 1

[0037] In the reactor, add successively 6.0kg of ethylene glycol, 6.0kg of 1,4-butanediol, 24.0kg of hydroxyl-terminated polybutadiene liquid rubber (molecular weight is 250, functionality is 1.9), 24.0kg of hexane Diacid and 2.4g titanium catalyst, turn on the stirring, start to heat up to 140°C, keep the temperature for 2 hours, stabilize the dehydration speed (through the rectification tower, the top temperature of the tower is kept at 90°C), continue to heat up to 170°C, turn on the vacuum pump, and control the vacuum degree slowly Slowly and gradually increase. Raise the temperature to 215°C for the transesterification reaction, and pass through nitrogen to take away the excess polyols and small molecule alcohols. After 5 hours from the start of vacuuming, take a sample every 2 hours for central control analysis until the final acid value is (0.1-0.6) mgKOH / About g, the hydroxyl value is 112.0mgKOH / g, return to normal pressure, drop to room temperature, discharge and sto...

Embodiment 2

[0039] In the reactor, add 13.8kg of ethylene glycol, 13.8kg of hydroxyl-terminated polyacrylonitrile liquid rubber (molecular weight is 500, functionality is 2.4), 32.4kg of adipic acid and 5.6g of titanium catalyst, turn on the stirring , start to heat up to 160 ° C, keep the temperature for 2 hours, stabilize the dehydration rate (through the rectification tower, the top temperature is maintained at 105 ° C), continue to heat up to 190 ° C, turn on the vacuum pump, and control the vacuum degree to gradually increase. Raise the temperature to 235°C for the transesterification reaction, and pass through nitrogen to take away the excess polyols and small molecule alcohols. After 5 hours from the start of vacuuming, take a sample every 2 hours for central control analysis until the final acid value is (0.1-0.6) mgKOH / g, the hydroxyl value is 56.0 mgKOH / g, return to normal pressure, cool down to room temperature, discharge and store to obtain liquid rubber modified polyester pol...

Embodiment 3

[0041] In the reactor, add successively 7.4kg of ethylene glycol, 7.4kg of 1,4-butanediol, 14.8kg of hydroxyl-terminated polyacrylonitrile liquid rubber (molecular weight is 500, functionality is 2.4), 30.4kg of adiponitrile acid and 6.6g of titanium catalyst, turn on the stirring, start to heat up to 160°C, keep the temperature for 2 hours, stabilize the dehydration rate (through the rectification tower, the top temperature is maintained at 105°C), continue to heat up to 190°C, turn on the vacuum pump, control the vacuum degree slowly Gradually increase. Raise the temperature to 235°C for the transesterification reaction, and pass through nitrogen to take away the excess polyols and small molecule alcohols. After 5 hours from the start of vacuuming, take a sample every 2 hours for central control analysis until the final acid value is (0.1-0.6) mgKOH / g, the hydroxyl value is 56.0 mgKOH / g, return to normal pressure, cool down to room temperature, discharge and store to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com