Polyether ether ketone foamed material and preparation method thereof

A technology of polyetheretherketone and foaming materials, which is applied in the field of preparation of polyether ether ketone foaming materials, can solve the problems of long-term stable use and low use temperature, and achieve reduced raw material consumption, short production cycle, and high production efficiency. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

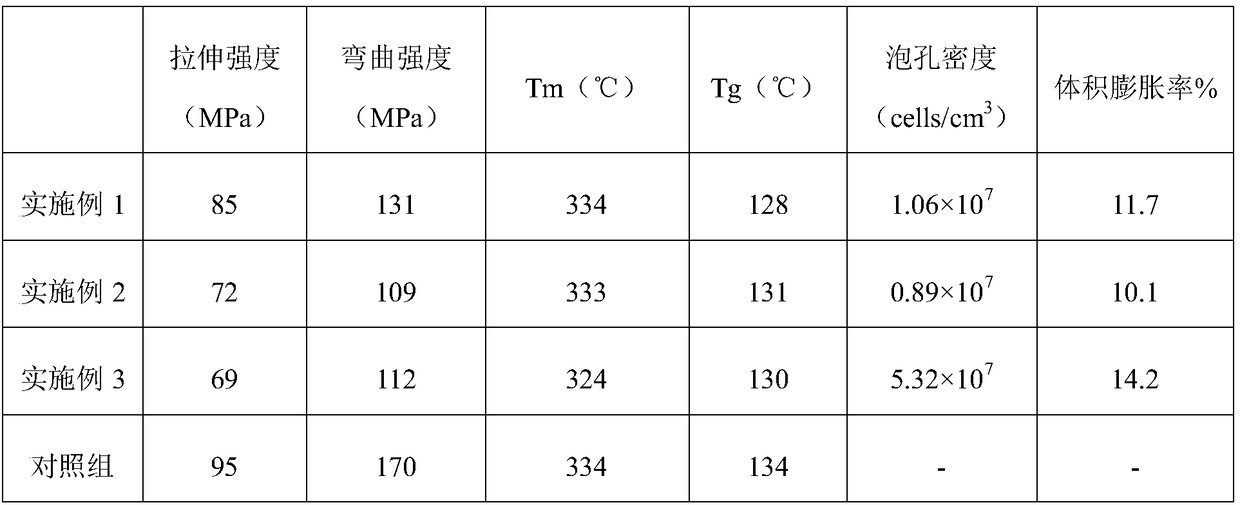

Examples

preparation example Construction

[0023] A preparation method of polyetheretherketone foaming material, comprising the following steps:

[0024] (1) Provide the above-mentioned raw materials for drying. The specific drying conditions are: polyether ether ketone particles, dry at 150-160°C for 220-240 minutes, and then cool to room temperature; polyimide, aluminum oxide, silicon dioxide , phenyl tetrazole were dried at 200-210°C for 180-200 minutes, and then cooled to room temperature; through drying, polyimide, aluminum oxide, silicon dioxide, phenyl tetrazole and polyetherether were effectively controlled The moisture content inside the ketone particles, if the moisture content in the raw material is too high, the water will be vaporized in advance at about 100°C during the foaming process, resulting in irregular foaming in the internal structure of the material. At the foaming temperature of critical carbon dioxide, the original bubbles will break, affecting the foaming rate and mechanical properties.

[00...

Embodiment 1

[0029] A polyether ether ketone foaming material, comprising the following raw materials in parts by mass: 8.5 kg of polyether ether ketone particles, 0.1 kg of supercritical carbon dioxide, 0.2 kg of phenyl tetrazole; 0.1 kg of polyimide , 0.1kg of aluminum oxide, 0.1kg of silicon dioxide with a particle size of 20nm; the melt index of polyetheretherketone particles is 20-25g / 10min. The purity of supercritical carbon dioxide is ≥99%.

[0030] A preparation method of polyetheretherketone foaming material, comprising the following steps:

[0031] (1) The above-mentioned raw materials are dried, and the specific drying conditions are:

[0032] PEEK particles, dried at 150°C for 240 minutes, then cooled to room temperature;

[0033] Polyimide, aluminum oxide, silicon dioxide, and phenyl tetrazole were dried at 200°C for 200 minutes, and then cooled to room temperature;

[0034] (2) Add the dried polyether ether ketone particles, polyimide, aluminum oxide, silicon dioxide, and ...

Embodiment 2

[0038] A polyether ether ketone foaming material, comprising the following raw materials in parts by mass: 9.5 kg of polyether ether ketone particles, 0.3 kg of supercritical carbon dioxide, 0.3 kg of phenyl tetrazole; 0.2 kg of polyimide , 0.3kg of aluminum oxide, 0.3kg of silicon dioxide with a particle size of 30nm; the melt index of polyether ether ketone particles is 20-25g / 10min. The purity of supercritical carbon dioxide is ≥99%.

[0039] A preparation method of polyetheretherketone foaming material, comprising the following steps:

[0040] (1) The above-mentioned raw materials are dried, and the specific drying conditions are:

[0041] PEEK particles, dried at 160°C for 220 minutes, then cooled to room temperature;

[0042] Polyimide, aluminum oxide, silicon dioxide, and phenyl tetrazole were dried at 210°C for 180 minutes, and then cooled to room temperature;

[0043] (2) Add the dried polyether ether ketone particles, polyimide, aluminum oxide, silicon dioxide, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com