Graphite modified water-coated anticorrosive resin and preparation method

A graphene-modified, anti-corrosion resin technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor outdoor weather resistance, poor hydrolysis resistance, slow drying of paint films, etc., achieve good water resistance and improve storage performance , the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A graphene-modified water-coated anticorrosion resin, in weight percentage, comprises 5% graphene dispersion liquid, 38% deionized water, 30% vegetable oil fatty acid, 15% pentaerythritol, 9.5% in this anticorrosion resin % phthalic anhydride, 0.1% antioxidant, 2% emulsifier, 0.4% pH regulator; the sum of the weight percentages of each component in the graphene modified water-coated anticorrosion resin is 100%.

[0032] The graphene dispersion is XF020 monolayer graphene oxide dispersion (Xianfeng Nano). The vegetable oil fatty acid is soybean oil. Described antioxidant is JYANOX-1010 antioxidant. Described emulsifier is EFS-1312 nonionic emulsifier (Shanghai Zhongcheng Fine Chemical Co., Ltd.). Described pH adjusting agent is potassium hydroxide.

[0033] The preparation method of above-mentioned graphene modified water-coated type anticorrosion resin comprises the following preparation steps:

[0034] (1) Put vegetable oil fatty acid, pentaerythritol, phthalic anh...

Embodiment 2

[0038] A graphene-modified water-coated anticorrosion resin, in weight percentage, comprises 10% graphene dispersion liquid, 35% deionized water, 26% vegetable oil fatty acid, 9% pentaerythritol, 16% in this anticorrosion resin % phthalic anhydride, 0.03% antioxidant, 3.5% emulsifier, 0.47% pH regulator; the sum of the weight percentages of each component in the graphene modified water-coated anticorrosion resin is 100%.

[0039] The graphene dispersion is XF020 single-layer graphene oxide dispersion. Described vegetable oil fatty acid is castor oil. Described antioxidant is JYANOX-1076 antioxidant. Described emulsifier is ES-1230 anionic emulsifier (Shanghai Zhongcheng Fine Chemical Co., Ltd.). The pH regulator is ammonia water.

[0040] The preparation method is the same as in Example 1.

Embodiment 3

[0042] A graphene-modified water-coated anticorrosion resin, in weight percentage, comprises 6% graphene dispersion liquid, 30% deionized water, 33% vegetable oil fatty acid, 14% pentaerythritol, 13% in this anticorrosion resin % phthalic anhydride, 0.08% antioxidant, 3.62% emulsifier, 0.3% pH regulator; the sum of the weight percentages of each component in the graphene modified water-coated anticorrosion resin is 100%.

[0043] The graphene dispersion is XF020 single-layer graphene oxide dispersion. The vegetable oil fatty acid is a mixture of refined linseed oil and coconut oil (weight ratio 1:1). Described antioxidant is JYANOX-1076 antioxidant. Described emulsifier is EFS-1312 nonionic emulsifier. The pH regulator is dimethylethanolamine.

[0044] The preparation method is the same as in Example 1.

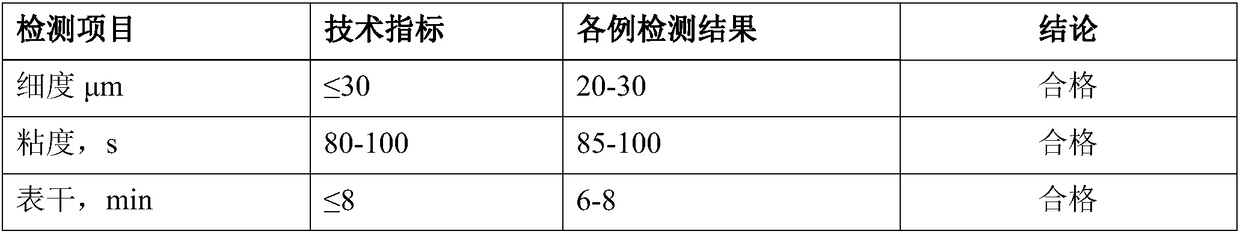

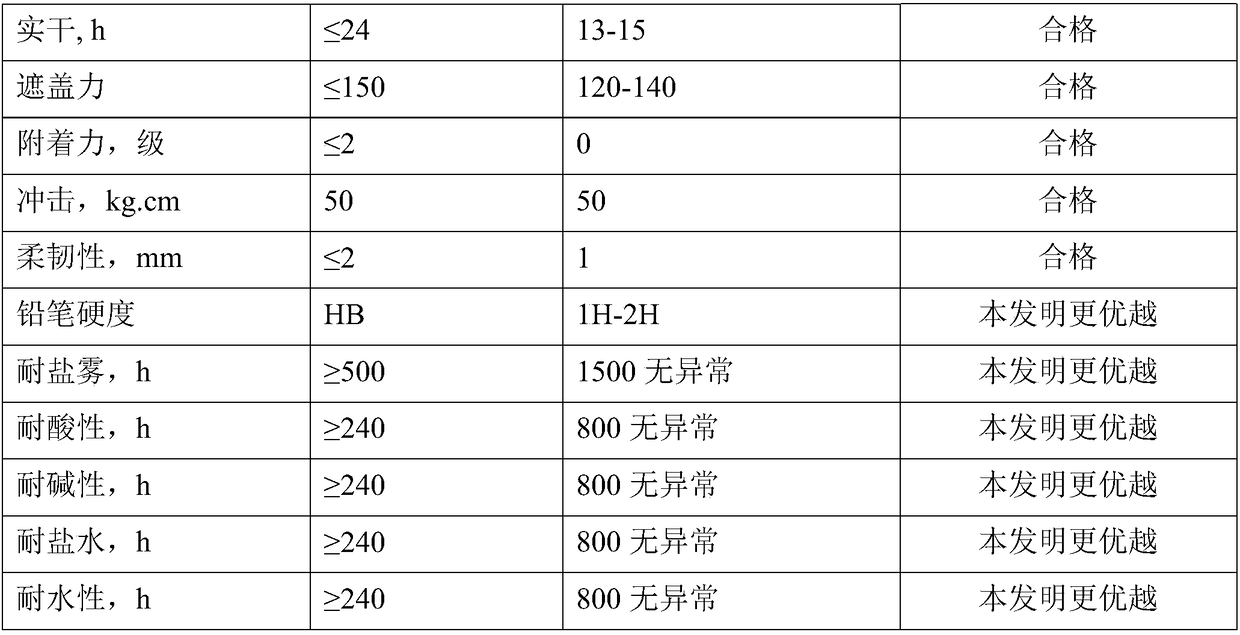

[0045] The graphene-modified water-coated anticorrosion resin described in any one of Examples 1 to 3 was used to prepare steel structure anticorrosion coatings, and the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com