A Suspension Bed Hydrogenation Process for Treating Heavy Oil

A suspended bed and heavy oil technology, which is applied in the fields of hydrogenation treatment process, hydrocarbon oil treatment, petroleum industry, etc., can solve the problems of insufficient reaction, uneven mixing, unsatisfactory separation effect of hydrogenation products, etc., to improve the conversion rate and The effect of light oil yield and good hydrogenation catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

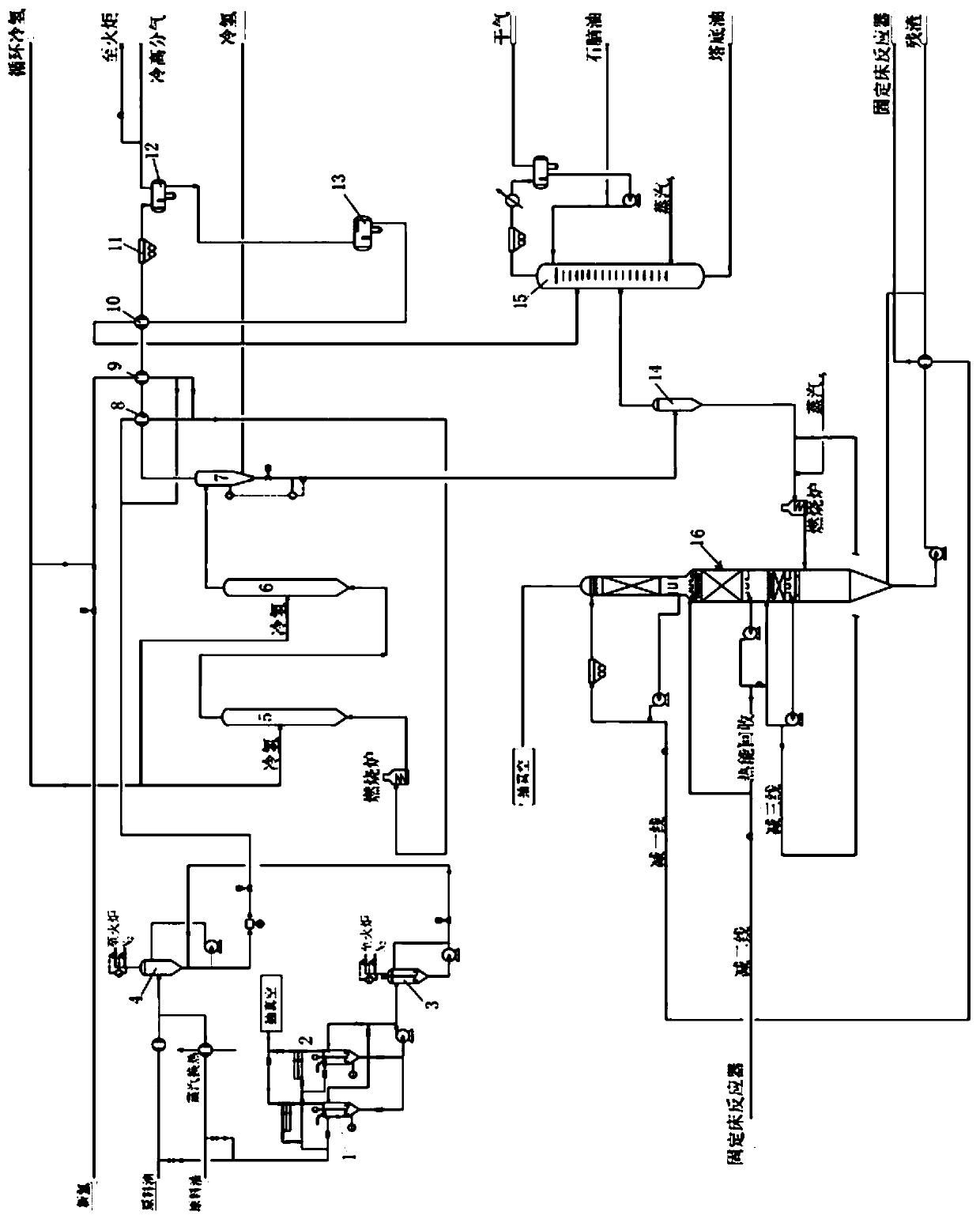

[0076] Such as figure 1 As shown, the suspended bed hydrogenation process for heavy oil provided in this embodiment includes the following steps:

[0077] (1) select residual oil as the raw material oil of this process, get half of the residual oil and mix it with the suspension bed hydrocracking catalyst to form a mixture, and carry out primary shear and secondary shear to the mixture successively, Obtain catalyst slurry;

[0078] (2) Mix the catalyst slurry with the remaining residual oil and hydrogen and send it into the suspension bed hydrogenation reactor, and control the operating pressure in the suspension bed hydrogenation reactor to 18MPa, the temperature to 425°C, and the volume of hydrogen oil The ratio is 1000 for hydrocracking reaction;

[0079] (3) After step (2) reacted for 1.5h, the obtained suspension bed hydrogenation product was subjected to thermal high-pressure separation at 18MPa and 400°C, and hot high-separation gas and hot high-separation oil were co...

Embodiment 2

[0084] Such as figure 1 As shown, the suspended bed hydrogenation process for heavy oil provided in this embodiment includes the following steps:

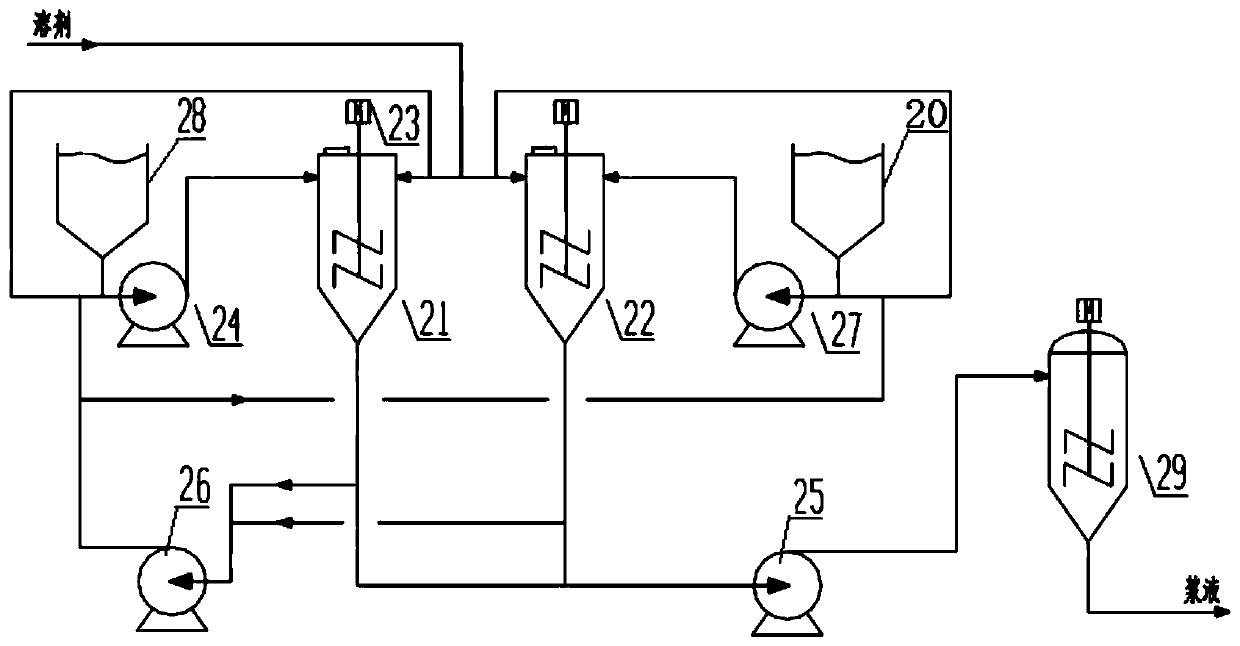

[0085] (1) Purification treatment of coal tar

[0086] Air is introduced into the coal tar so that the particle size is 0.2mm and the specific surface area is 50m 2 / g of kaolin powder and coal tar are back-mixed and contacted at a mass ratio of 0.1:1 and adsorbed at 50°C and 0.5MPa. The air flow required for each 1kg of kaolin powder is 0.5m 3 / s; After the adsorption is completed, settle and stratify, collect the upper layer material, and then perform solid-liquid separation on the upper layer material, and the collected liquid phase is the purified coal tar;

[0087] Compared with the coal tar before the purification treatment, the residual carbon value in the coal tar after the purification of this embodiment is reduced to 0.1%, which is reduced by 79%; the content of asphaltene is reduced by 76%; the colloid is reduced by 80...

Embodiment 3

[0095] Such as figure 1 As shown, the suspended bed hydrogenation process for heavy oil provided in this embodiment includes the following steps:

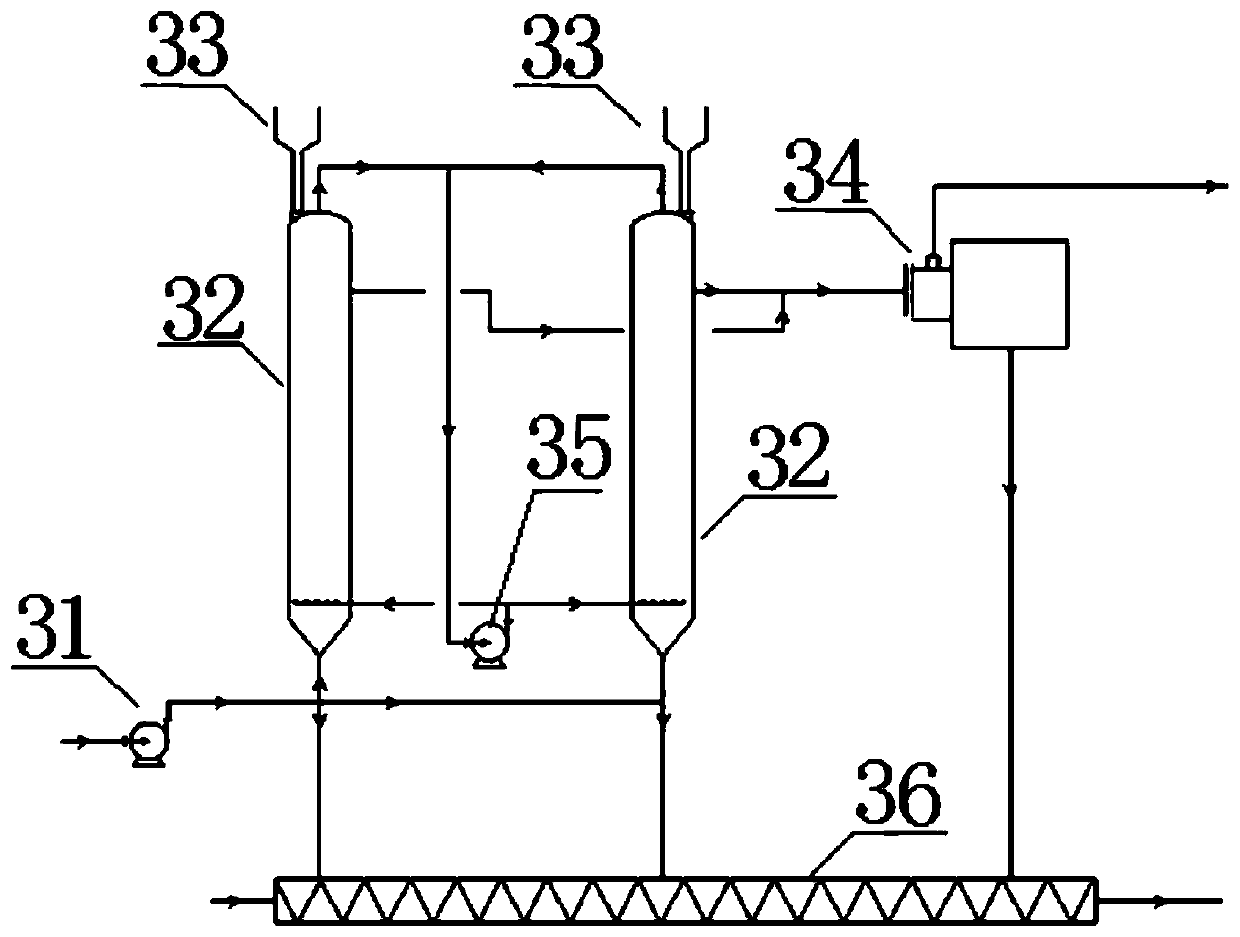

[0096] (1) Preparation of catalyst slurry

[0097] Select coal tar as the raw material oil of this process, please refer to Figure 5 Take half the amount of coal tar and inject it into the solvent buffer tank 51, after being buffered by the solvent buffer tank 51 and pressurized by the solvent booster pump 58, it enters the Venturi tube 56, and at the same time, the suspended bed hydrocracking catalyst enters from the solid catalyst The material system 55 also enters into the Venturi tube 56, and the coal tar and the catalyst are initially mixed in the Venturi tube 56 and then enter the slurry preparation tank 52, and form a primary slurry under the agitation of the stirring device 54, which is prepared in the tank. The temperature is 90°C, and the pressure in the preparation tank is normal; then the first-stage slurry is sheare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com